High-Temperature Resistant Label Typography Design

Sticker labels are an essential component in various industries, serving as a means to convey important information about products, ensure brand recognition, and facilitate efficient logistics. However, in certain environments where extreme temperatures are present, ordinary sticker labels may fail to withstand the harsh conditions and lose their functionality. To address this challenge, the development of high-temperature resistant label typography design has become crucial. This article explores the significance of such designs and their impact on the sticker label industry.

The Importance of High-Temperature Resistance

In industries like automotive, aerospace, and manufacturing, where high temperatures are common, traditional sticker labels often face significant challenges. The extreme heat can cause labels to fade, peel, or even disintegrate, rendering them ineffective. This can lead to critical issues such as loss of product identification, compromised safety, and hindrance to efficient operations.

High-temperature resistant label typography design aims to overcome these challenges by utilizing materials and techniques specifically engineered to withstand extreme heat. These labels are designed to maintain their integrity, legibility, and adhesive properties even in the most demanding conditions.

The Role of Typography in High-Temperature Resistance

Typography plays a crucial role in ensuring the durability and readability of high-temperature resistant labels. The choice of fonts, sizes, and styles directly impacts the label's ability to withstand heat and maintain its visual appeal. Here are some key considerations:

1. Font Selection

When designing labels for high-temperature environments, it is essential to choose fonts that can withstand heat without distortion or degradation. Fonts with thick strokes and minimal intricate details tend to perform better in extreme conditions. Sans-serif fonts, such as Arial or Helvetica, are often preferred due to their simplicity and legibility.

2. Size and Scaling

The size of the typography is critical in ensuring readability from a distance or in challenging conditions. High-temperature resistant labels often need to be visible even in environments with limited lighting or through protective gear. Scaling the typography appropriately ensures that the label remains legible under adverse circumstances.

3. Contrast and Color

Choosing the right color palette and contrast is vital for high-temperature resistant labels. Colors that are easily distinguishable from the background and provide high contrast enhance legibility. Opting for bold, high-contrast color combinations, such as black on white or yellow on black, helps ensure visibility even in extreme heat.

The Advancements in High-Temperature Resistant Materials

As technology progresses, the sticker label industry has witnessed advancements in materials designed to withstand high temperatures. These materials offer enhanced durability, adhesion, and resistance to heat-induced degradation. Some notable advancements include:

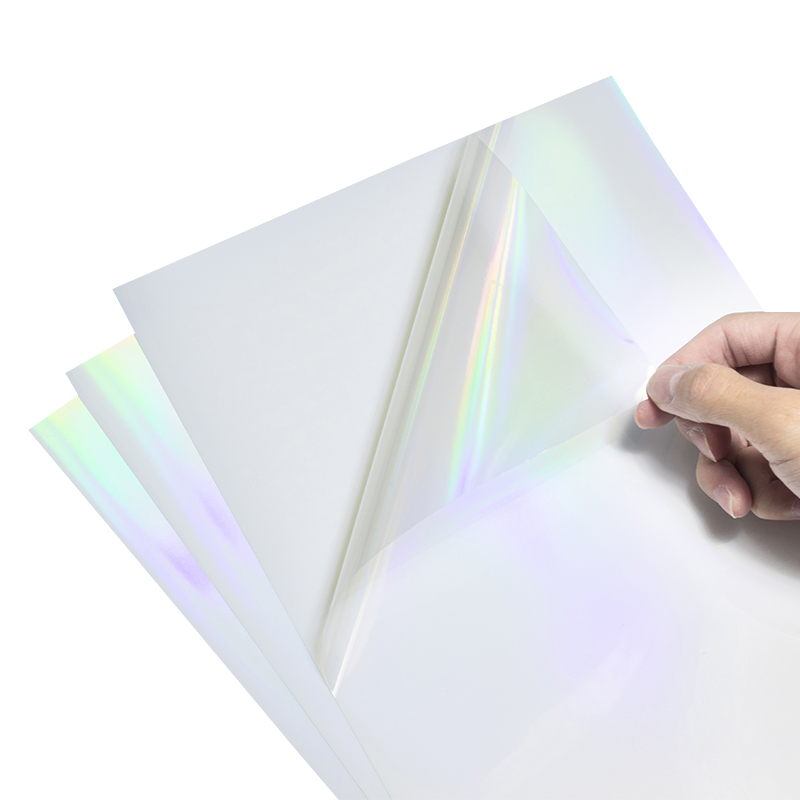

1. Heat-Resistant Substrates

New substrates, such as polyimide or ceramic-based materials, have been developed to withstand extreme temperatures. These materials can maintain their structural integrity and adhesive properties even when exposed to temperatures exceeding 500°C.

2. Resilient Adhesives

Adhesives specifically formulated for high-temperature environments have become increasingly prevalent. These adhesives are designed to resist heat-induced degradation, ensuring that labels remain firmly attached to products or surfaces despite extreme conditions.

3. Protective Coatings

Applying protective coatings over label typography can significantly enhance its resistance to heat, chemicals, and other environmental factors. These coatings act as a barrier, safeguarding the label and preserving its legibility and functionality for extended periods.

Conclusion

The development of high-temperature resistant label typography design has revolutionized the sticker label industry, enabling labels to withstand extreme heat and maintain their functionality in challenging environments. Through careful font selection, appropriate sizing, and consideration of contrast and color, labels can remain legible and effective even in the harshest conditions. With advancements in materials and adhesives, the future of high-temperature resistant labels looks promising, ensuring the safety, efficiency, and reliability of various industries.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.