The Materials Used in High-Temperature Resistant Sticker Labels

Sticker labels are ubiquitous in our daily lives, serving a wide range of purposes, from branding products to conveying important information. In various industries, such as automotive, electronics, and manufacturing, sticker labels must withstand extreme temperatures. This article delves into the fascinating world of high-temperature resistant sticker labels and the materials that make them durable and reliable.

The Importance of High-Temperature Resistance

High-temperature resistant sticker labels are essential for environments where extreme heat is a constant challenge. Think of applications like automotive engines, industrial machinery, or even kitchen appliances. The labels on these items need to withstand not only high temperatures but also potential exposure to oils, chemicals, and physical abrasion. This is where the choice of materials becomes crucial.

Polyimide Labels: The Industry Standard

Polyimide is the material of choice when it comes to high-temperature resistant sticker labels. It offers exceptional thermal stability and resistance to a wide range of chemicals and solvents. Polyimide labels are renowned for their ability to maintain their integrity even in extreme heat, making them the preferred choice for many industries.

One of the standout features of polyimide labels is their resistance to temperatures exceeding 500 degrees Fahrenheit (260 degrees Celsius). This exceptional heat resistance makes them invaluable in industries where extreme temperatures are a constant challenge, such as aerospace and automotive manufacturing.

Silicone Labels: A Versatile Alternative

Silicone labels are another option for applications that require high-temperature resistance. While they might not match the extreme heat resistance of polyimide labels, silicone labels can still withstand temperatures of up to 392 degrees Fahrenheit (200 degrees Celsius). Additionally, they offer excellent resistance to UV radiation and harsh chemicals.

Industries that focus on outdoor equipment, such as solar panels and outdoor electronics, often opt for silicone labels due to their versatility and durability. They provide a strong balance between temperature resistance and cost-effectiveness.

Ceramic Labels: Extreme Heat Champions

In situations where the temperature is off the charts, such as in certain specialized industrial processes, ceramic labels are the champions of high-temperature resistance. These labels can endure temperatures exceeding 2000 degrees Fahrenheit (1093 degrees Celsius). Ceramic labels are crafted from high-quality ceramic materials that can withstand extreme thermal stress.

Industries like metallurgy, glass manufacturing, and foundries rely on ceramic labels to ensure that critical information and identification remain intact even in the harshest conditions. These labels are an essential component of quality control and safety protocols in extreme-heat environments.

Label Adhesives and Backings

The material of the label itself is only part of the equation. The adhesive used to affix the label to the substrate is equally important. For high-temperature resistant labels, silicone-based adhesives are often the preferred choice. Silicone adhesives maintain their properties at elevated temperatures and adhere well to various surfaces.

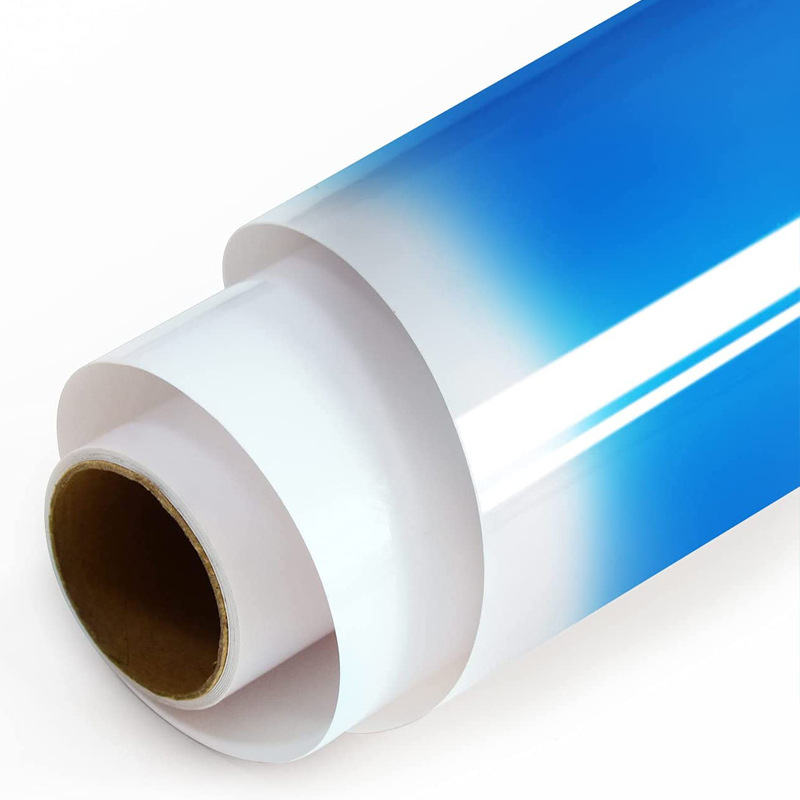

As for the backing material, it's typically a release liner or backing paper that protects the adhesive until the label is applied. The choice of backing material should be compatible with the label material and the intended application environment. In high-temperature scenarios, it's essential that the backing material doesn't break down or weaken under heat stress.

Conclusion

High-temperature resistant sticker labels play a vital role in numerous industries where extreme heat and challenging conditions are a constant. The choice of materials, such as polyimide, silicone, or ceramic, is determined by the specific needs of the application and the temperature ranges involved. These labels not only convey important information but also ensure safety and quality control in environments where temperature extremes are a daily reality.

Understanding the materials and adhesives used in high-temperature resistant labels is key to selecting the right solution for your industry, be it automotive, electronics, aerospace, or heavy manufacturing. With these durable labels, businesses can continue to function effectively even in the hottest of conditions.

When it comes to high-temperature resistant sticker labels, the materials make all the difference. Whether it's the exceptional heat resistance of polyimide, the versatility of silicone, or the extreme capabilities of ceramic, these labels are the unsung heroes of industries that operate in the hottest of environments.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.