Non-Upturning, Enduring High-Temperature Labels: Wholesale Manufacturing Excellence**

The sticker label industry has seen significant advancements in recent years, with a focus on creating labels that can withstand high temperatures without upturning or losing their integrity. This development has paved the way for a niche market of wholesale manufacturers specializing in producing these specialized labels. In this article, we will delve into the intricacies of non-upturning, enduring high-temperature labels and the wholesale manufacturers that excel in this field.

**The Importance of Non-Upturning, Enduring High-Temperature Labels**

Non-upturning, enduring high-temperature labels play a crucial role in industries where extreme heat is a common factor. These labels are engineered to maintain their structural integrity even in environments where temperatures soar to levels that would cause conventional labels to deteriorate. This capability is invaluable in sectors such as automotive, aerospace, and industrial manufacturing, where precision and durability are paramount.

Manufacturers in these industries rely on these specialized labels to provide critical information, warnings, and identification, ensuring that their products perform optimally under the most demanding conditions. The ability of these labels to endure high temperatures without upturning is a testament to the precision and quality that goes into their production.

**Wholesale Manufacturing: Meeting Industry Demands**

Wholesale manufacturers specializing in non-upturning, enduring high-temperature labels play a pivotal role in meeting the demands of industries that require these specialized products. These manufacturers employ state-of-the-art technology and employ skilled professionals with expertise in materials science and label production.

One of the key advantages of sourcing from wholesale manufacturers is the economies of scale they offer. By producing labels in large quantities, they can provide cost-effective solutions without compromising on quality. Additionally, these manufacturers often have the capacity for customization, allowing clients to tailor labels to their specific requirements.

**Materials and Manufacturing Processes**

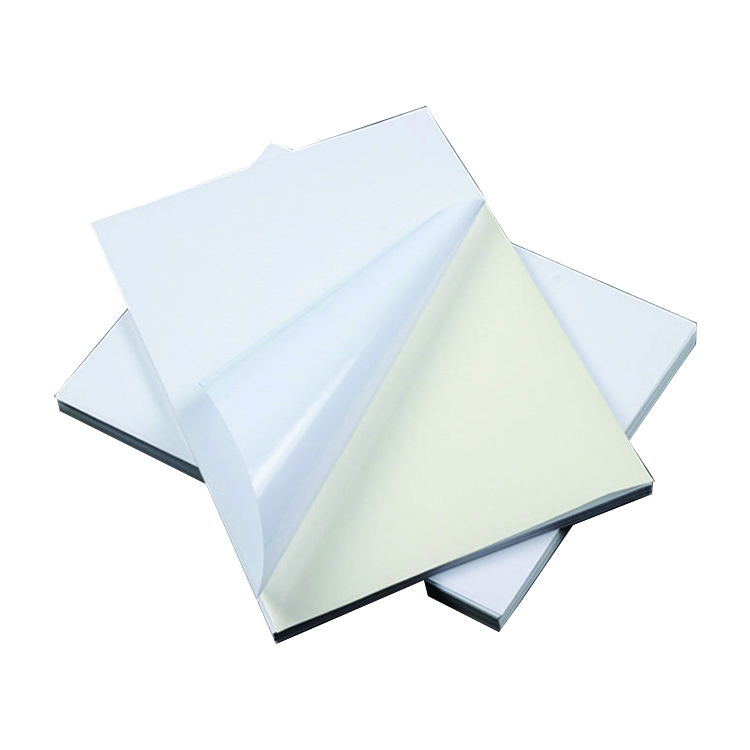

The production of non-upturning, enduring high-temperature labels requires a meticulous selection of materials and precise manufacturing processes. These labels are typically made from specialized materials such as heat-resistant polymers, ceramics, and metals. These materials undergo rigorous testing to ensure they meet the stringent standards for high-temperature endurance.

The manufacturing process involves precision cutting, printing, and finishing techniques. Advanced printing technologies, such as thermal transfer printing and laser marking, are employed to ensure the durability and legibility of the labels. Additionally, special adhesives are used to ensure that the labels remain securely affixed even in high-temperature environments.

**Quality Assurance and Compliance**

Wholesale manufacturers of non-upturning, enduring high-temperature labels adhere to strict quality assurance protocols. Each batch of labels undergoes thorough testing to verify their performance under extreme heat conditions. This ensures that the labels meet or exceed industry standards for durability and longevity.

Furthermore, these manufacturers are well-versed in industry regulations and compliance standards. They work closely with regulatory bodies to ensure that their labels meet all necessary requirements for use in specific industries. This commitment to compliance gives clients confidence in the reliability of the labels they receive.

**Conclusion: Elevating Industry Standards**

Non-upturning, enduring high-temperature labels have revolutionized industries that operate in extreme heat environments. The expertise and precision of wholesale manufacturers in producing these labels have elevated industry standards, providing a vital component for the success of businesses in sectors ranging from aerospace to automotive.

By prioritizing quality, customization, and compliance, these manufacturers continue to play a pivotal role in ensuring that products perform optimally even in the harshest conditions. As technology advances and industries continue to push boundaries, the role of non-upturning, enduring high-temperature labels and their dedicated manufacturers will only become more crucial.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.