The Dynamics of Heat-Resistant Label Paper in the Sticker Label Industry

Sticker labels have become an indispensable component of modern product packaging and branding strategies. Among the myriad choices in the label industry, heat-resistant label paper has emerged as a key player, offering unique properties that cater to specific applications. This article delves into the intricacies of heat-resistant label paper, exploring its transparency, toxicity, and the implications for the sticker label industry.

Understanding Heat-Resistant Label Paper

Heat-resistant label paper is engineered to withstand elevated temperatures without compromising its structural integrity or print quality. This specialized material finds applications in various industries, ranging from food and beverage to electronics. The transparency of heat-resistant label paper is a crucial factor that influences its suitability for specific use cases.

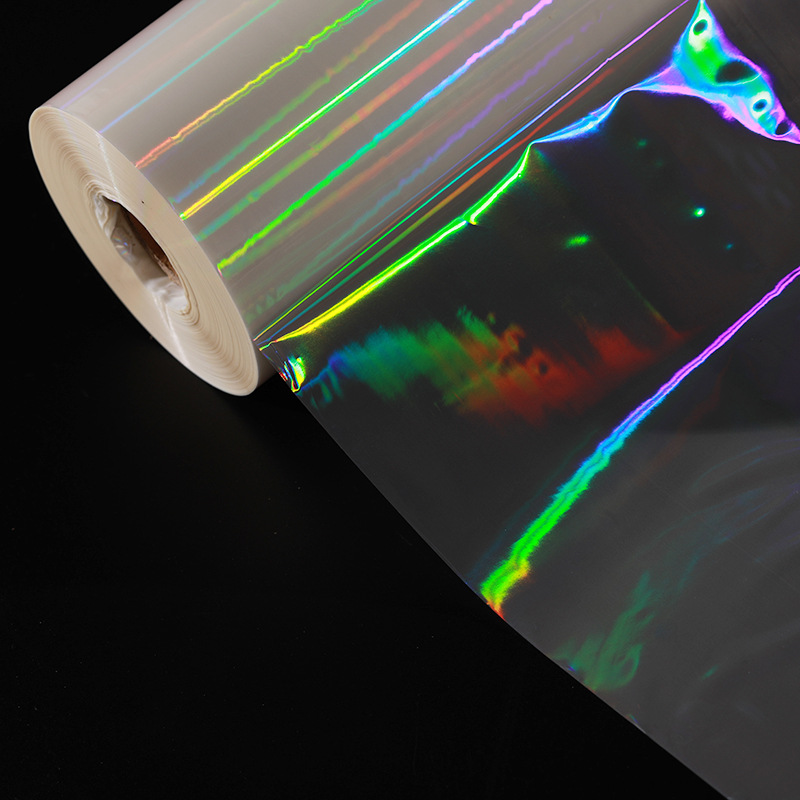

Transparency: A Critical Attribute

The transparency of heat-resistant label paper is a key determinant of its effectiveness in different applications. Transparent labels are often preferred for products where showcasing the contents or maintaining visibility is essential. Heat-resistant label paper, with its transparent properties, provides a clear window to the underlying surface, enabling manufacturers to convey information and branding elements seamlessly.

The Toxicity Quandary

Concerns regarding the toxicity of label materials have gained prominence in recent years. As the sticker label industry strives for sustainability and compliance with environmental regulations, the toxicity of label materials, including heat-resistant label paper, is a topic of scrutiny.

Toxicity Assessment of Heat-Resistant Label Paper

The toxicity of heat-resistant label paper is a multifaceted consideration, involving the evaluation of its constituent materials and the potential release of harmful substances under different conditions. Regulatory standards and industry certifications play a pivotal role in assessing and ensuring the safety of label materials.

Regulatory Compliance and Industry Standards

Sticker label manufacturers are obligated to adhere to stringent regulatory standards governing the production and use of label materials. Compliance with international standards such as REACH and RoHS is imperative to ensure that heat-resistant label paper meets established safety benchmarks.

Environmental Impact

Beyond toxicity, the environmental impact of heat-resistant label paper is a crucial aspect to consider. The sticker label industry is increasingly focused on adopting eco-friendly practices, and the choice of label materials contributes significantly to a product's overall sustainability profile.

Innovation in the Sticker Label Industry

The sticker label industry is characterized by a continuous pursuit of innovation to meet evolving market demands. Advances in material science and manufacturing technologies contribute to the development of heat-resistant label papers with enhanced properties, addressing both transparency and environmental considerations.

Conclusion

In conclusion, the dynamics of heat-resistant label paper in the sticker label industry are shaped by its transparency, toxicity considerations, and the broader context of regulatory compliance and environmental impact. As the industry navigates these complexities, the quest for innovative label solutions remains paramount, ensuring that sticker labels not only meet functional requirements but also align with sustainability goals.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.