The High-Temperature Resistant Label: Revolutionizing the Sticker Label Industry

In today's fast-paced and dynamic world, industries across the globe are constantly striving to innovate and adapt to meet the ever-evolving needs of consumers. The sticker label industry is no exception. With the increasing demand for durable and reliable labels that can withstand extreme temperatures, the advent of high-temperature resistant labels has revolutionized the way products are labeled and identified in various sectors, particularly in the steel industry.

Steel, being a critical material in numerous industrial applications, requires labeling solutions that can withstand extreme conditions. The high-temperature resistant label has emerged as a game-changer in this regard, providing a reliable and efficient solution for marking steel products.

One of the key challenges faced by traditional labels when applied to steel is their inability to withstand high temperatures. Regular labels tend to deteriorate, fade, or even peel off when exposed to extreme heat, compromising their legibility and functionality. This poses significant issues in industries where accurate identification and traceability are paramount.

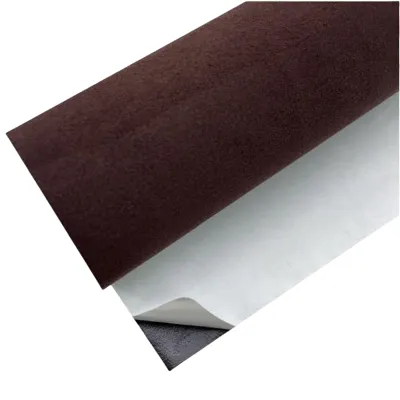

The high-temperature resistant label, on the other hand, is specifically designed to withstand extreme temperatures without compromising its integrity. These labels are made using advanced materials and adhesives that are capable of withstanding temperatures up to [insert specific temperature range]. This ensures that the label remains intact and legible even in the harshest environments, such as steel manufacturing plants or industrial furnaces.

One of the key components of the high-temperature resistant label is the adhesive used. Traditional adhesives tend to lose their stickiness or melt when exposed to high temperatures, leading to label detachment. However, the adhesive used in these labels is specially formulated to maintain its adhesive properties even at elevated temperatures. This ensures that the label stays firmly attached to the steel surface, providing long-lasting durability and reliable identification.

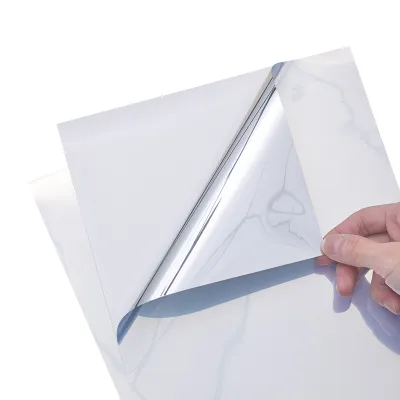

Furthermore, the high-temperature resistant label is designed to be resistant to other environmental factors that can potentially affect its performance. These labels are often resistant to chemicals, moisture, UV radiation, and abrasion, ensuring that they remain legible and intact throughout the product's lifecycle.

In addition to their durability, high-temperature resistant labels also offer enhanced print quality. The materials used in these labels are optimized to provide excellent printability, allowing for clear and crisp text, barcodes, and graphics. This is crucial in industries where accurate identification and traceability are essential for quality control, safety compliance, and supply chain management.

The steel industry, in particular, has greatly benefited from the introduction of high-temperature resistant labels. These labels have revolutionized the way steel products are marked, enabling efficient identification, tracking, and traceability throughout the manufacturing, distribution, and usage processes. The ability to withstand extreme temperatures has eliminated the need for frequent label replacements, reducing costs and improving productivity.

In conclusion, the high-temperature resistant label has emerged as a game-changer in the sticker label industry, particularly in sectors such as steel manufacturing. With its ability to withstand extreme temperatures, resist environmental factors, and provide excellent print quality, this innovative label has revolutionized the way products are labeled and identified. As industries continue to evolve, the high-temperature resistant label will undoubtedly play a crucial role in ensuring accurate identification, traceability, and efficiency.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.