How to Use High-Temperature Resistant Label Paper in Printing Factory

In the sticker label industry, high-temperature resistant label paper plays a crucial role in ensuring that labels maintain their quality and readability in extreme heat conditions. This specialized label paper is designed to withstand high temperatures without smudging or fading, making it ideal for various applications such as industrial labeling, automotive parts labeling, and more. In this article, we will explore the proper usage of high-temperature resistant label paper in a printing factory.

1. Selecting the Right High-Temperature Resistant Label Paper

Choosing the appropriate high-temperature resistant label paper is the first step towards ensuring successful printing. Consider the following factors:

a) Temperature range: Determine the maximum temperature the label will be exposed to and select label paper that can withstand that range.

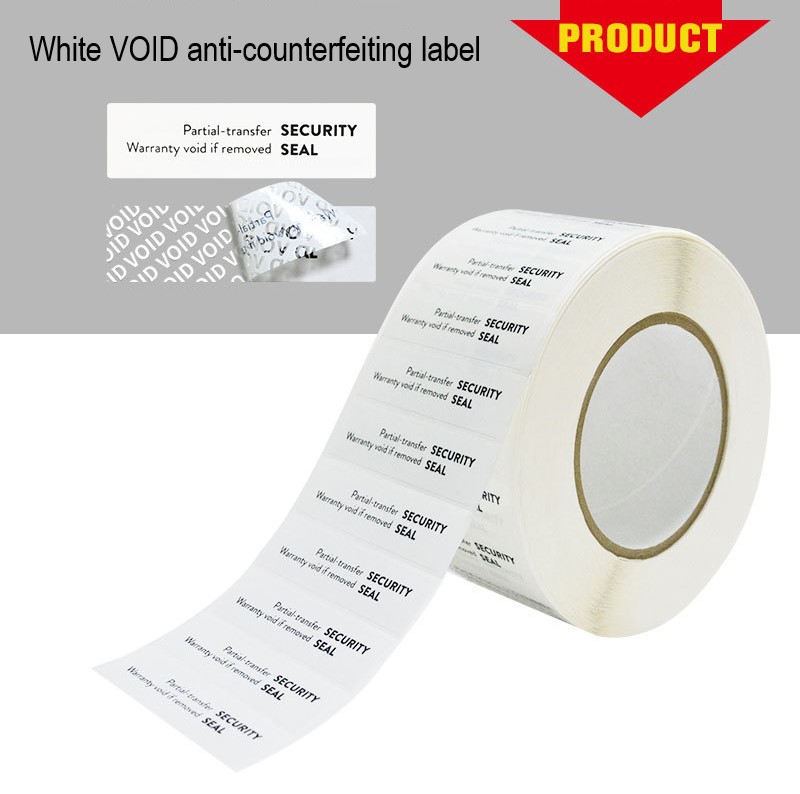

b) Adhesive strength: Ensure that the label paper has a strong adhesive that can withstand high temperatures without peeling off or losing its grip.

c) Compatibility: Check if the label paper is compatible with your printing equipment, ink, and other printing materials.

2. Preparing the Printing Equipment

Before printing, it is essential to prepare the printing equipment to ensure optimal results:

a) Clean the printer: Make sure the printer is free from dust, debris, or any residue that could affect the print quality or cause jams.

b) Calibrate the printer: Adjust the printer settings to match the label paper specifications, including temperature settings, print speed, and print density.

3. Printing Process

Follow these steps to print using high-temperature resistant label paper:

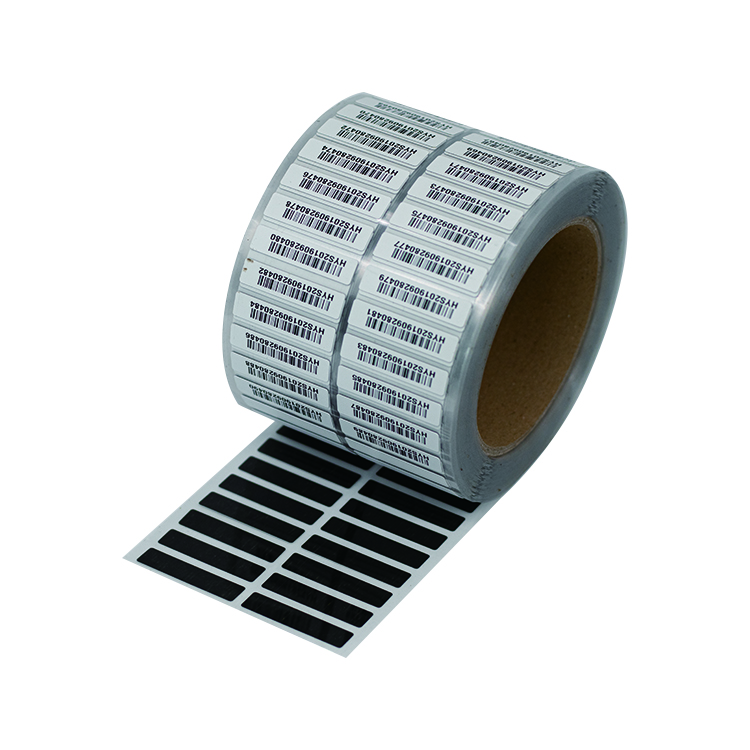

a) Design the label: Use professional design software to create the label layout, considering the required information, font size, and any additional graphics or logos.

b) Load the label paper: Ensure that the label paper is loaded correctly, aligning it with the printer's feeding mechanism to avoid misalignment or paper jams.

c) Adjust print settings: Set the printer to the appropriate temperature, print speed, and density recommended for the high-temperature resistant label paper.

d) Print a test label: Before printing a large batch, it is advisable to print a test label to ensure the desired print quality and adherence to the label paper.

4. Post-Printing Considerations

Once the labels are printed, it is crucial to handle them properly to maintain their integrity:

a) Allow drying time: Give the labels sufficient time to dry and set before handling or applying them to surfaces. This will prevent smudging or any damage to the printed information.

b) Storage conditions: Store the printed labels in a cool and dry environment to maintain their adhesive strength and overall quality.

c) Application process: Follow the recommended application instructions provided by the label paper manufacturer to ensure proper adhesion and longevity.

Conclusion

Using high-temperature resistant label paper in a printing factory requires careful consideration of various factors, including paper selection, equipment preparation, and proper printing techniques. By following the steps outlined in this article, you can ensure that your labels maintain their quality and readability even in extreme heat conditions. Remember to always choose the appropriate label paper and adhere to the manufacturer's guidelines for optimal results.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.