The Cost of Heat-Resistant Label Printing in the Sticker Label Industry

In the sticker label industry, heat-resistant labels play a crucial role in various applications that require durability and resistance to high temperatures. These labels are designed to withstand extreme heat without losing their adhesive properties or deteriorating in quality. If you are considering heat-resistant label printing for your business needs, it is essential to understand the cost factors involved. In this article, we will explore the key elements that contribute to the overall cost of heat-resistant label printing.

Label Material

The choice of label material significantly impacts the cost of heat-resistant label printing. Various materials, such as polyester, polyimide, and vinyl, are commonly used for heat-resistant labels. Each material has its unique characteristics and price range. Polyester labels, for example, offer excellent heat resistance and are relatively affordable. On the other hand, polyimide labels have exceptional thermal stability but tend to be more expensive. Vinyl labels strike a balance between cost and performance. The material you choose will depend on your specific requirements and budget.

Printing Technique

The printing technique employed also affects the cost of heat-resistant label printing. Different methods, such as flexographic printing, digital printing, and screen printing, offer varying levels of quality, durability, and cost. Flexographic printing is a popular choice for large-scale production, offering cost-effective solutions for heat-resistant label printing. Digital printing, although more expensive, provides high-quality results with the added advantage of customization and shorter turnaround times. Screen printing, while durable, is often used for specialized applications and may be more costly.

Label Size and Shape

The size and shape of the labels you require will impact the overall cost. Larger labels typically require more material and ink, resulting in higher costs. Similarly, complex shapes may require additional die-cutting processes, which can increase the price. It is essential to consider your specific labeling needs and balance them with your budget to determine the most cost-effective size and shape for your heat-resistant labels.

Quantity

The quantity of heat-resistant labels you need will also influence the cost. Printing labels in bulk generally reduces the per-unit cost, as economies of scale come into play. However, it is crucial to strike a balance between ordering in large quantities and avoiding excess inventory. Carefully assess your labeling requirements and consider factors such as shelf life and demand fluctuations to determine the optimal quantity that aligns with your budget.

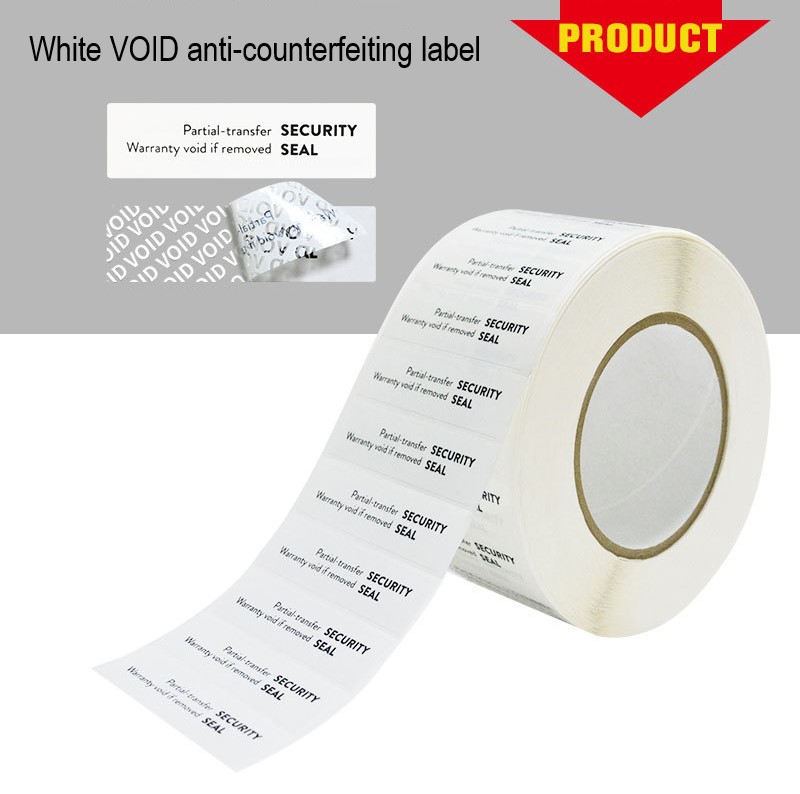

Additional Features

Additional features, such as custom designs, colors, finishes, and special adhesives, can increase the cost of heat-resistant label printing. Custom designs and colors often require additional setup and printing processes, which can add to the overall expense. Special finishes, such as gloss or matte coatings, may enhance the label's appearance but can also impact the price. Additionally, if your application requires unique adhesives, such as high-tack or low-tack options, the cost may vary accordingly. Consider the necessity of these additional features and weigh them against your budget to make informed decisions.

Conclusion

Heat-resistant label printing in the sticker label industry involves several factors that contribute to the overall cost. The choice of label material, printing technique, size and shape, quantity, and additional features all play a significant role in determining the final price. It is crucial to assess your specific requirements, consider your budget, and work closely with a reputable label printing company to find the optimal balance between cost and quality. By understanding these cost factors, you can make informed decisions and ensure that your heat-resistant labels meet your business needs effectively.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.