High-Temperature Resistant Labels: Ensuring Quality and Durability

Sticker labels play a crucial role in various industries, providing essential information, branding, and identification. In certain environments, such as those with high temperatures, standard labels may not withstand the conditions, leading to readability issues and potential safety concerns. To address this challenge, high-temperature resistant labels have been developed, offering exceptional durability and quality. In this article, we will explore the key aspects of these labels, their applications, and the importance of choosing the right supplier.

The Importance of High-Temperature Resistance

High-temperature resistant labels are specifically designed to withstand extreme heat conditions without compromising their adhesive properties or readability. Whether it's in automotive, aerospace, industrial, or electronic industries, where elevated temperatures are common, these labels ensure that vital information remains intact and visible.

One of the primary challenges faced by standard labels in high-temperature environments is adhesive failure. When exposed to excessive heat, the adhesive used in regular labels can deteriorate, resulting in peeling or detachment. High-temperature resistant labels, on the other hand, are equipped with specialized adhesives that can withstand extreme temperatures, ensuring long-lasting adherence.

Quality Considerations for High-Temperature Resistant Labels

When it comes to high-temperature resistant labels, ensuring quality is of utmost importance. Here are some key considerations:

1. Temperature Range:

High-temperature resistant labels should be able to withstand a wide range of temperatures, from moderate heat to extreme conditions. It is crucial to choose labels that are specifically designed to meet the temperature requirements of your application.

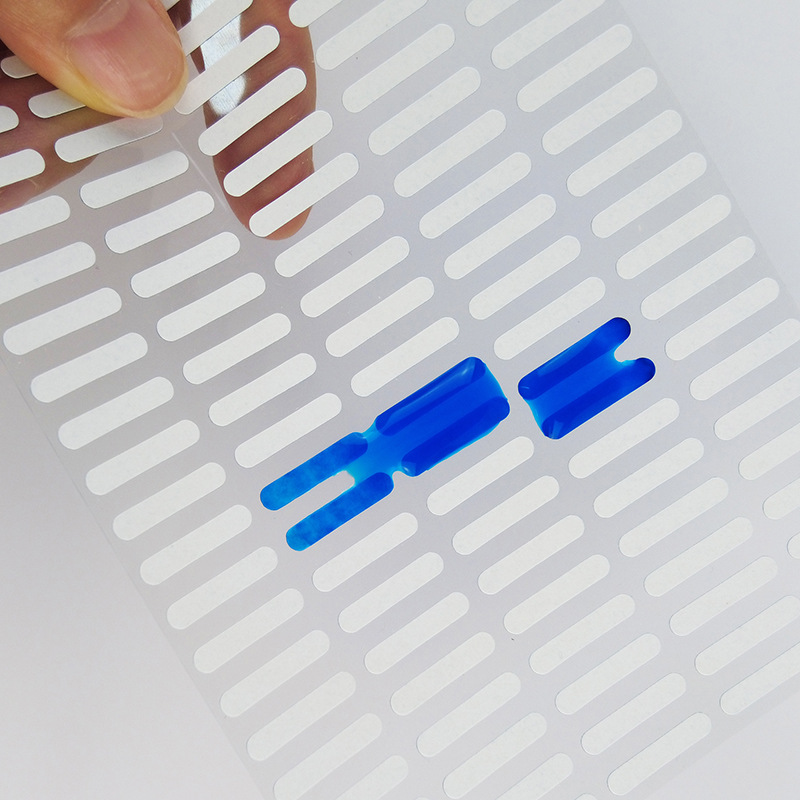

2. Material:

The material used in high-temperature resistant labels should be able to endure the heat without warping, discoloration, or degradation. Common materials include polyester, polyimide, and aluminum, each offering different levels of resistance and durability.

3. Adhesive:

The adhesive used in these labels should be capable of maintaining strong adhesion even at high temperatures. Silicone-based adhesives are commonly used due to their excellent heat resistance properties.

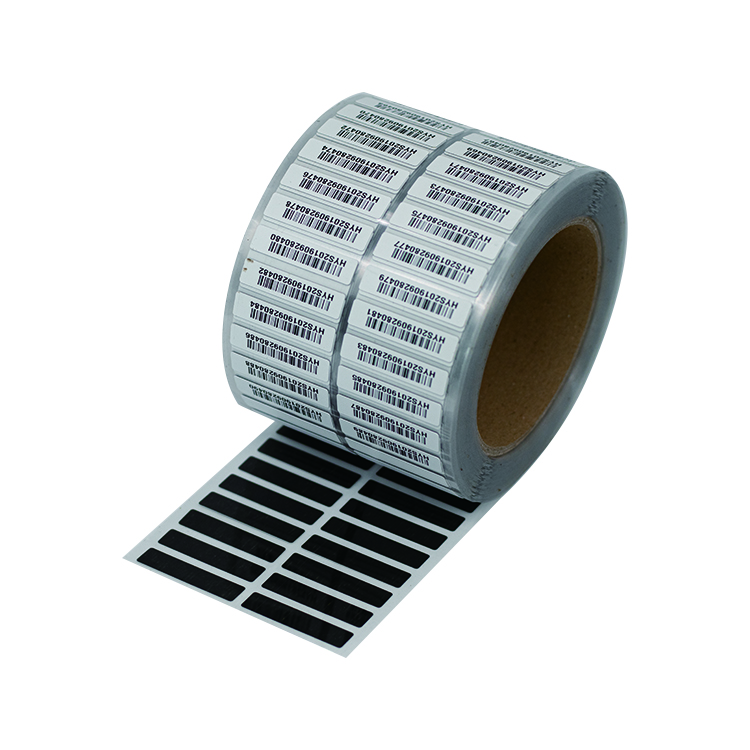

4. Print Quality:

High-temperature resistant labels should provide clear and legible printing, ensuring that important information remains readable even in extreme conditions. High-quality printing techniques, such as thermal transfer or laser printing, are often employed to achieve this.

Applications of High-Temperature Resistant Labels

The applications of high-temperature resistant labels are diverse and vital in various industries. Some notable examples include:

1. Automotive Industry:

In the automotive industry, high-temperature resistant labels are used on engine components, exhaust systems, and braking systems, where temperatures can reach extremely high levels. These labels ensure that critical information, such as part numbers, safety warnings, and barcodes, remain visible and intact.

2. Aerospace Industry:

Within the aerospace industry, high-temperature resistant labels are employed on aircraft engines, turbines, and other critical components. These labels withstand the extreme temperatures experienced during flight, ensuring that maintenance and safety information is readily available.

3. Industrial Applications:

In industrial settings, high-temperature resistant labels are used on machinery, equipment, and pipes that are exposed to high temperatures. These labels provide essential instructions, warning signs, and identification, helping to ensure operational safety and efficiency.

Choosing the Right Supplier

Given the critical nature of high-temperature resistant labels, it is essential to choose a reliable and experienced supplier. When selecting a supplier, consider the following:

1. Expertise:

Look for a supplier with extensive experience in producing high-temperature resistant labels for your specific industry. They should have a deep understanding of the unique requirements and challenges faced in your field.

2. Quality Assurance:

Ensure that the supplier follows strict quality control processes to guarantee the reliability and durability of their labels. Ask for certifications and testimonials from satisfied customers to assess their track record.

3. Customization Options:

Choose a supplier who can offer customized high-temperature resistant labels tailored to your specific needs. This includes options for size, shape, material, and printing, allowing you to meet your application requirements effectively.

In conclusion, high-temperature resistant labels are essential in industries where extreme heat conditions are prevalent. These labels ensure durability, legibility, and adherence even in the harshest environments. By considering the quality aspects and selecting the right supplier, you can ensure that your high-temperature resistant labels meet the stringent requirements of your industry.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.