High-Temperature Resistant Label Layout Design

In the sticker label industry, the design of high-temperature resistant labels plays a crucial role in ensuring the durability and legibility of information in extreme conditions. These labels are specifically engineered to withstand elevated temperatures, making them suitable for various applications in industries such as automotive, aerospace, electronics, and manufacturing. In this article, we will explore the key considerations and best practices for designing high-temperature resistant labels.

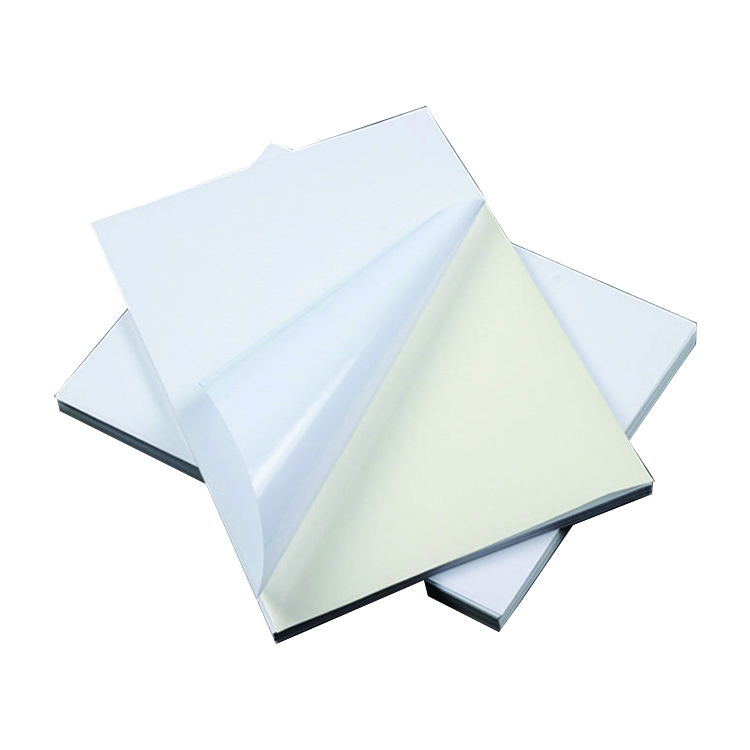

Material Selection

The choice of materials for high-temperature resistant labels is of paramount importance. Labels intended for use in extreme heat must be able to withstand prolonged exposure to high temperatures without compromising their adhesive properties or readability. Common materials used for such labels include:

- Polyester (PET): Polyester labels offer excellent resistance to heat, chemicals, and abrasion. They are capable of withstanding temperatures up to 300°C, making them suitable for various industrial applications.

- Polyimide (PI): Polyimide labels are known for their exceptional thermal stability. They can withstand temperatures up to 500°C, making them ideal for applications in extreme heat environments.

- Ceramic: Ceramic labels are highly resistant to heat and can withstand temperatures exceeding 1000°C. They are commonly used in industries where extreme temperatures are encountered, such as foundries and metalworking plants.

Label Design

When designing high-temperature resistant labels, it is important to consider several factors to ensure optimal performance. These factors include:

- Font Selection: Choose a font that is legible even in small sizes and can withstand the effects of heat. Fonts with bold and simple designs are often preferred for high-temperature labels.

- Contrast: Ensure a high contrast between the label background and the text or graphics to enhance readability. Dark-colored labels with light-colored text or graphics are commonly used to achieve this.

- Information Hierarchy: Clearly define the hierarchy of information to ensure that critical details are easily distinguishable. Use font size, weight, and positioning to differentiate between important and secondary information.

- Graphics and Symbols: Incorporate relevant graphics and symbols to convey information quickly and effectively. Symbols that indicate temperature resistance or cautionary signs can enhance the label's usability.

Label Placement

The proper placement of high-temperature resistant labels is crucial to ensure their effectiveness and longevity. Consider the following guidelines:

- Surface Compatibility: Ensure that the label material is compatible with the surface it will be applied to. Different materials may adhere differently to various surfaces, so it is essential to choose the appropriate adhesive for optimal bonding.

- Clean and Dry Surface: Before applying the label, ensure that the surface is clean and free from any contaminants or moisture. This will help maximize adhesion and prevent label failure.

- Orientation: Place the label in a position that ensures maximum visibility and readability. Consider the angle at which the label will be viewed and position it accordingly for optimal impact.

Conclusion

Designing high-temperature resistant labels requires careful consideration of materials, design elements, and placement. By selecting the appropriate materials, designing labels with clear information hierarchy, and ensuring proper placement, these labels can withstand extreme temperatures and provide essential information in challenging environments. The sticker label industry continues to innovate and develop new solutions to meet the demands of various industries requiring high-temperature resistant labels.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.