The Cost of High-Temperature Label Printing in the Sticker Label Industry

In the sticker label industry, high-temperature label printing plays a crucial role in various sectors such as manufacturing, automotive, and aerospace. These labels are designed to withstand extreme temperatures and harsh environments, providing vital information, tracking, and identification. However, one common question that arises is: How much does high-temperature label printing cost?

When it comes to determining the cost of high-temperature label printing, several factors come into play. Let's explore these factors to gain a better understanding of the pricing structure.

1. Material Selection

The choice of materials for high-temperature label printing significantly impacts the cost. Different materials offer varying levels of durability, adhesion, and resistance to heat. Common materials used for high-temperature labels include polyester, polyimide, and ceramic. Polyester labels are cost-effective, while polyimide and ceramic labels are more expensive due to their exceptional heat resistance properties.

2. Label Size and Quantity

The size and quantity of labels required also affect the overall cost. Larger labels or bulk orders often result in higher prices due to increased material consumption and production complexity. Manufacturers usually offer volume discounts, making it more cost-effective to order larger quantities of high-temperature labels.

3. Printing Techniques

The printing technique employed for high-temperature labels can influence the cost. Common printing methods include thermal transfer, screen printing, and digital printing. Thermal transfer printing is a popular choice for high-temperature labels due to its durability, but it can be more expensive than other methods. Screen printing and digital printing offer cost-effective alternatives, especially for smaller quantities or intricate designs.

4. Specialized Features

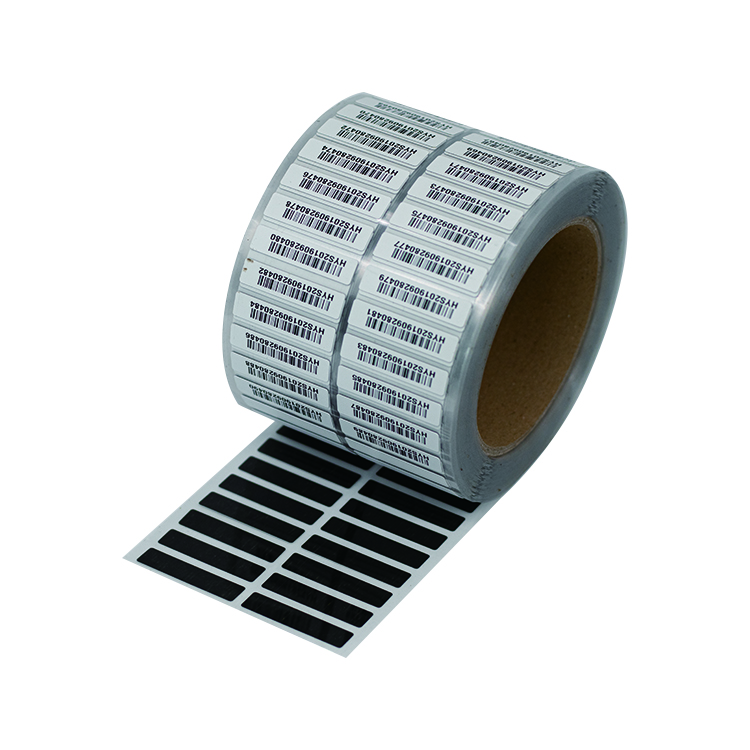

Some high-temperature labels may require additional specialized features, such as barcodes, QR codes, or variable data. These features add value but can also increase the overall cost. The complexity of the design and the technology required to incorporate these features will impact the final price.

5. Supplier Selection

The choice of supplier also plays a significant role in determining the cost of high-temperature label printing. Different suppliers have varying pricing structures, quality standards, and production capabilities. It is crucial to research and compare multiple suppliers to ensure you receive the best value for your investment.

Conclusion

High-temperature label printing is an essential aspect of the sticker label industry, providing durability and reliability in extreme conditions. When considering the cost of high-temperature label printing, factors such as material selection, label size and quantity, printing techniques, specialized features, and supplier selection must be taken into account. By understanding these factors, businesses can make informed decisions and find the most cost-effective solution that meets their specific requirements.

Remember, the cost of high-temperature label printing can vary significantly depending on individual needs and preferences. It is always recommended to consult with industry professionals or suppliers to get accurate pricing information tailored to your specific project.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.