High-temperature Resistant Label Machine Manufacturer: Revolutionizing the Sticker Label Industry

The sticker label industry has witnessed significant advancements in recent years, with one of the key players being high-temperature resistant label machine manufacturers. These manufacturers have revolutionized the industry by introducing cutting-edge technology and innovative solutions that cater to the growing demand for durable and reliable labels in high-temperature environments.

Meeting the Challenges of High Temperatures

High-temperature environments pose unique challenges for labels, as traditional labels often fail to withstand extreme heat. Industries such as automotive, aerospace, electronics, and manufacturing require labels that can endure high temperatures without compromising their quality or readability. High-temperature resistant label machine manufacturers have risen to this challenge by developing specialized equipment and materials that can withstand the harshest conditions.

These manufacturers employ advanced printing techniques and utilize specially formulated inks and adhesives that can withstand temperatures ranging from 300 to 1000 degrees Fahrenheit. By incorporating heat-resistant materials into their label production process, they ensure that the labels remain intact and legible, even in extreme heat.

Advancements in Label Printing Technology

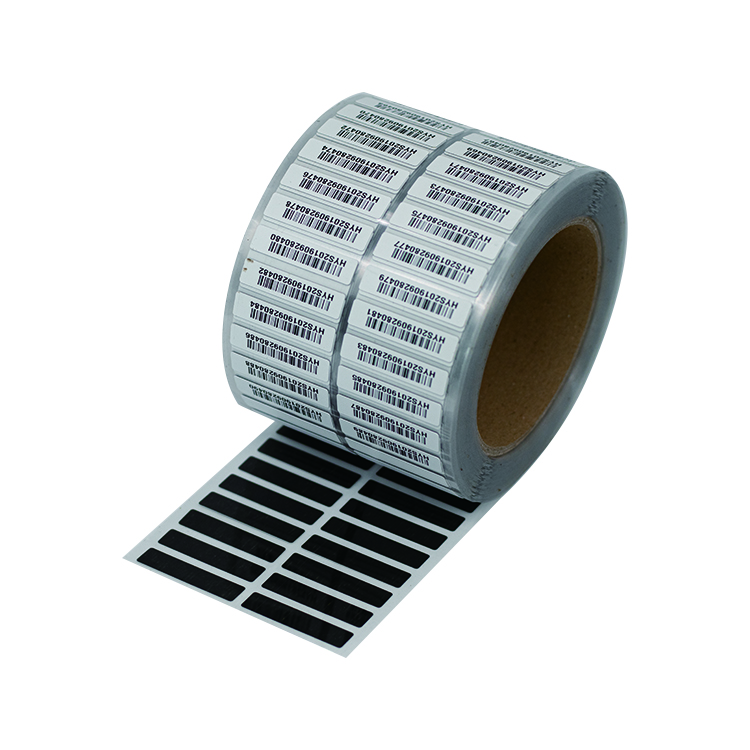

The high-temperature resistant label machine manufacturers have not only focused on developing heat-resistant materials but have also made significant strides in label printing technology. They have introduced state-of-the-art printing machines that offer high-resolution printing, allowing for precise and detailed label designs.

These machines utilize thermal transfer printing technology, which involves the transfer of ink from a ribbon onto the label material. This process ensures that the labels maintain their integrity and readability, even in high-temperature environments. Additionally, the use of thermal transfer printing eliminates the risk of smudging or fading, ensuring that the labels remain clear and legible throughout their lifecycle.

Customization and Versatility

High-temperature resistant label machine manufacturers understand the diverse requirements of different industries and offer a wide range of customization options. They provide labels in various shapes, sizes, and colors, allowing businesses to create labels that align with their branding and application needs.

Moreover, these manufacturers offer versatile label materials that can be used on a variety of surfaces, including metals, plastics, ceramics, and composites. This versatility enables businesses to label their products and equipment effectively, regardless of the material's composition or the application's specific requirements.

Ensuring Compliance and Safety

In industries where safety and compliance regulations are stringent, high-temperature resistant labels play a crucial role. Manufacturers in these sectors rely on labels to provide vital information, warnings, and instructions to ensure the safety of their employees and end-users.

High-temperature resistant label machine manufacturers understand the importance of compliance and safety and develop labels that meet the necessary standards. These labels are designed to withstand extreme temperatures, harsh chemicals, and other challenging conditions, ensuring that critical information remains visible and intact.

The Future of High-Temperature Resistant Labels

The sticker label industry continues to evolve, driven by the demand for labels that can withstand high temperatures and challenging environments. High-temperature resistant label machine manufacturers are at the forefront of this evolution, constantly pushing the boundaries of technology and innovation.

As industries such as automotive, aerospace, and manufacturing continue to grow, the need for high-temperature resistant labels will only increase. Manufacturers will strive to develop labels that can withstand even higher temperatures, longer durations, and more extreme conditions. With advancements in materials, printing technology, and customization options, high-temperature resistant labels will continue to play a vital role in various industries.

In conclusion, high-temperature resistant label machine manufacturers have transformed the sticker label industry by addressing the unique challenges posed by high-temperature environments. Through their advanced printing technology, heat-resistant materials, customization options, and commitment to safety and compliance, they have revolutionized the way labels are produced and used. The future of high-temperature resistant labels looks promising, as manufacturers continue to innovate and meet the growing demands of various industries.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.