High temperature resistant ceramic label

The materials used are stainless steel and ceramic glaze, which are composite together. The substrate is stainless steel and the surface is ceramic. They are fused together through high-temperature sintering at around 1200 degrees Celsius. On the high-strength alumina engineering ceramic substrate, barcode labels are generated by high-temperature glaze firing. The barcode symbols are well protected by transparent high-temperature glaze, and the ceramic barcode can withstand extremely harsh environments such as acid, alkali, salt, fog, sunlight exposure, and even flame grilling for a long time

The excellent performance of liquefied gas cylinder barcodes precisely meets the requirements of permanent automatic identification and labeling of gas cylinders, and the existing commercialized products that have undergone batch durability testing

The basic information of high-temperature resistant ceramic labels is as follows

1. Base material: stainless steel 304, industrial 99 ceramic powder

2. Surface glaze material: imported transparent glaze porcelain glaze

3. Label size: The size can be customized according to user requirements

4. Barcode parameters: one-dimensional barcode, two-dimensional barcode, barcode format, size, resolution and other technical parameters can be customized according to user requirements

5. High temperature resistance (up to 1200 ° C or above), acid, alkali, salt, and mist corrosion resistance, and resistance to organic solvent scrubbing

6. The text information on the surface of porcelain tiles is not easy to scratch and can last for decades without fading, making it a permanent barcode for use

7. Barcode resistant to high temperature of 1200 degrees Celsius

8. The impact resistance of the steel cylinder QR code is tested using a 10 meter drop test. After free fall, the ceramic on the surface remains undamaged

High temperature resistant aluminum foil hang tag

High temperature resistant hang tag is an aluminum foil coated with high-temperature resistant coating, mainly developed for the growing demand of customers in the steel industry for product traceability. It is specifically used on steel and aluminum molded parts. This material can resist the influence of surrounding factors such as climate and industrial environment, such as oil pollution, emulsifiers, acid and alkali erosion, as well as the impact of harsh weather conditions such as wind, rain, lightning and ultraviolet rays during transportation and storage, ensuring excellent performance in various extreme and harsh application environments. In order to ensure smooth waste discharge, suitable die-cutting knives should be specially selected for processing

Suitable for high-temperature industrial applications. Because of its high initial viscosity and final viscosity, it can be adhered to various substrates, including metal sheets with medium and low energy

Product Parameters

Coating: White

Thickness: 80 ml

Substrate: Aluminum

Temperature resistance range -40 ° C; C-600° C labeling temperature: 250 ℃ C-300 ℃

Product Features

Maximum resistance to high temperature of 600 ℃

Tensile, tear, and friction resistance

Resistant to strong acids and other chemical reagents

No need for cooling, directly heat apply

Can be directly printed by a heat transfer label printer

High temperature resistant polyimide sticker

High temperature resistant barcode label is an opaque polyimide (high temperature resistant) label with permanent acrylic pressure-sensitive adhesive and a white surface layer suitable for heat transfer printing. It is designed to meet the high temperature requirements of reflow soldering (260 ℃) and wave soldering (350 ℃) environments, and is specifically designed for character or barcode identification on printed circuit boards or related electronic components. In addition, the labels are designed to resist corrosive fluxes and multiple rounds of cleaning commonly used in circuit board applications, making them ideal materials that can withstand the erosion of various soldering agents, melting agents, and cleaning agents encountered in the production process of circuit boards

Features

There are two types of substrates: P and PET

UL94 VTM-0 & VTM-1 fire rating certification (flame retardant)

Compliant with FAR smoke and toxic gas standards

Compliant with BSS 7238& 7239 standard

High temperature resistance, chemical resistance

Compliant with REACH and ROHS standards, halogen-free

Suitable for SMT surface mount manufacturing process of PCB circuit boards, it is a special label for printed circuit board (PCB) identification (commonly used for temperature resistance of 260 ℃ for 6 minutes). After passing through the furnace, it does not bubble, curl, glue, yellow, or be easily corroded by various chemical substances in the flux

High temperature resistant and removable vinyl sticker

Ethylene based removable stickers have a removable adhesive backing that can be peeled off and re applied multiple times without leaving any adhesive residue on the product. It can be used at a temperature of 120 ℃, and at a temperature of 150 ℃, it can be used for a short period of time. It is coated with a removable and soluble acrylic adhesive, which can be easily peeled off from one backing material and stuck to another. The label is intact and can be reused multiple times. It is easy to tear off and will not leave any marks. With the development of society, the usability of removable adhesive stickers has gradually increased in demand in various industries and has been widely used.

Suitable for high-temperature processes such as sheet metal painting, masking, baking, glass curing, etc. (commonly used for temperature resistance of 0-150 ° C for 20 minutes), it does not bubble, curl, glue, yellow, or easily corrode by various chemical substances in the flux after passing through the furnace.

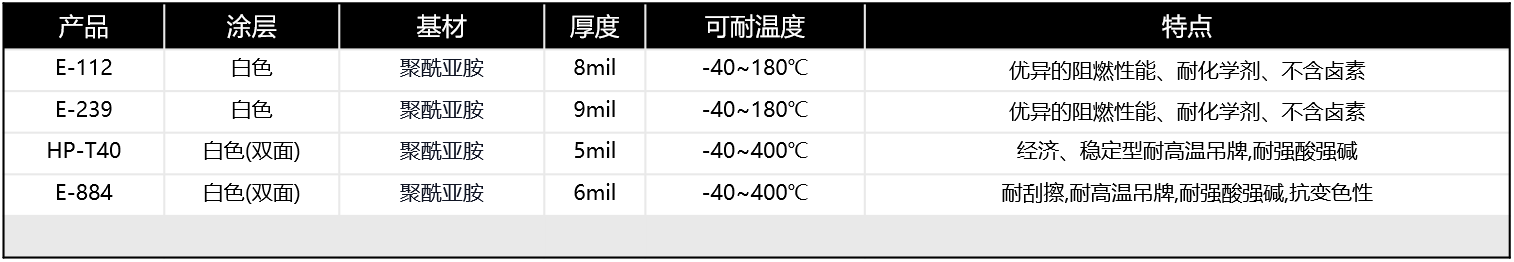

High temperature resistant polyimide tag material

High temperature resistant polyimide tags are used in extremely harsh production environments for steel, aluminum, and their castings. They can be applied in heat treatment production operations and hung on products as tags for production management and traceability. They have good resistance to deformation, solvents, and high temperatures

Application

Production management, traceability

Steel wire, steel coil, steel block

Aluminum products, stainless steel

Special steel tempering and annealing

High pressure gas cylinder

Automotive Parts

Inventory management, process management

Features and Advantages

Multiple materials and different thicknesses< br /> High cost-effectiveness

Excellent printing and printing effect

Can withstand 300 degrees Celsius; C high temperature

Acid resistant and suitable for open flames

Resistant to chemicals, moisture, and dirt

Economic and stable high-temperature resistant steel hang tag

High temperature resistant steel tag material list

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.