The Significance of Solvent-Resistant Sticker Labels

Solvent-resistant sticker labels play a pivotal role in various industries where durability and longevity are paramount. These labels are designed to withstand exposure to a wide range of solvents, ensuring that crucial information remains intact in demanding environments.

Understanding Solvent Resistance

Solvent resistance is a critical characteristic in sticker label manufacturing. It involves the ability of a label to maintain its adhesive properties and structural integrity when exposed to solvents commonly used in specific industries. This resistance is particularly essential in sectors such as chemical manufacturing, automotive, and healthcare.

Applications in Chemical Manufacturing

In the chemical manufacturing industry, where exposure to various solvents is inevitable, solvent-resistant sticker labels find extensive use. These labels are applied to chemical containers, providing essential information about the product, including handling instructions, chemical composition, and safety precautions.

Solvent Resistance in Automotive Labels

Automotive applications demand labels that can withstand exposure to fuels, oils, and cleaning solvents. Solvent-resistant sticker labels in this sector are utilized for product identification, branding, and compliance labeling on parts and components. The resilience of these labels ensures that vital information remains intact throughout the vehicle's lifespan.

Healthcare Industry Requirements

In the healthcare sector, where sterilization and chemical cleaning are routine processes, solvent-resistant labels are indispensable. These labels are commonly used on medical equipment, pharmaceutical packaging, and laboratory supplies. Their ability to resist solvents ensures that crucial information, such as expiration dates and dosage instructions, remains legible and accurate.

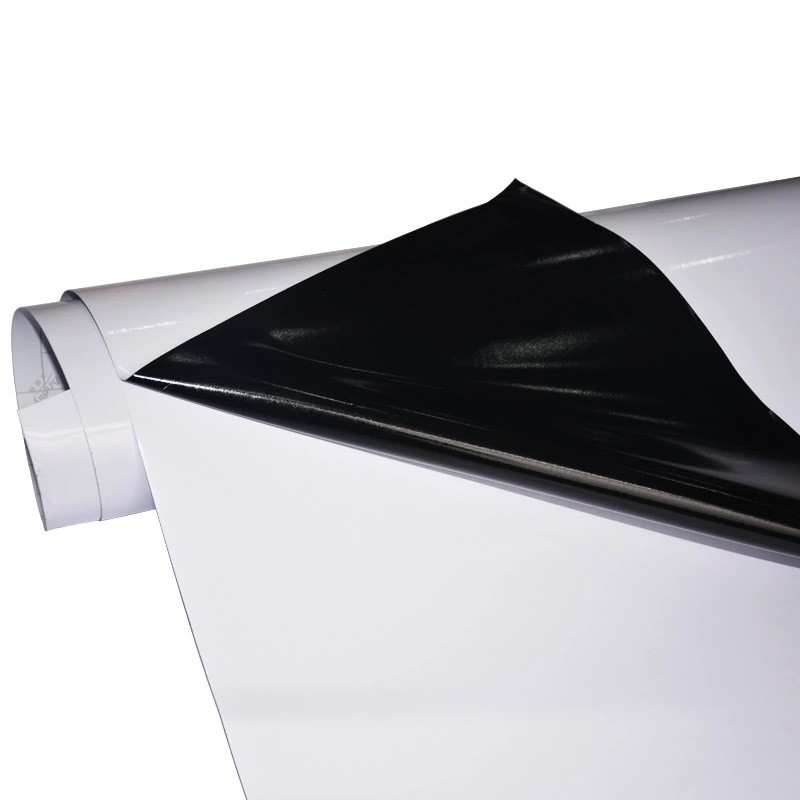

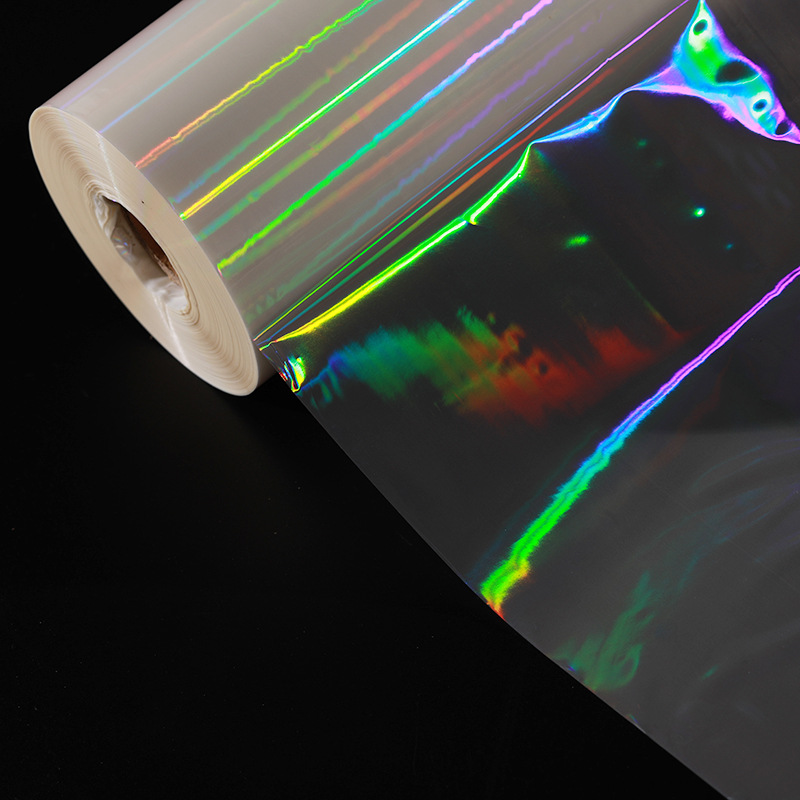

Material Selection and Manufacturing Process

The production of solvent-resistant sticker labels involves meticulous material selection and a specialized manufacturing process. High-quality materials, including solvent-resistant adhesives and durable label substrates, are chosen to withstand the harsh effects of solvents without compromising performance.

Quality Assurance and Testing

To guarantee the effectiveness of solvent-resistant labels, rigorous quality assurance measures and testing protocols are implemented. These tests assess the labels' resistance to a variety of solvents, ensuring that they meet industry standards for durability and longevity.

Conclusion

In conclusion, solvent-resistant sticker labels are indispensable in industries where exposure to solvents is a common occurrence. From chemical manufacturing to healthcare and automotive applications, the ability of these labels to withstand harsh environments ensures the integrity of crucial information. The meticulous selection of materials, coupled with rigorous quality assurance, makes solvent-resistant sticker labels a reliable solution for demanding labeling requirements.

```We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.