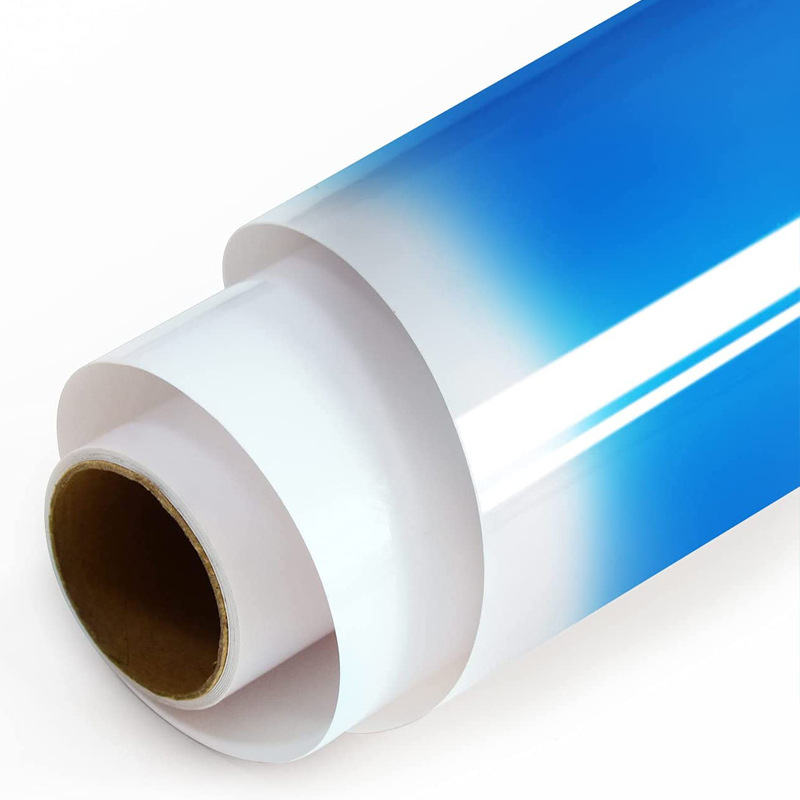

Hot stamping film

Hot stamping film, also known as aluminum foil (the term aluminum foil is more commonly used in the printing industry), is a hot stamping material made by coating and vacuum evaporating a thin film substrate with a layer of metal foil. The thickness of aluminum foil is generally (12, 16, 18, 20)μ m. 500-1500mm wide. Electrochemical aluminum foil is made by coating a release layer, a color layer, vacuum aluminum plating, and then coating a glue layer on a thin film, and finally rewinding the finished product

1. Specifications:

Thickness: 0.012mm Width: 0.64m, 1.28m

Length: 120m, 180m, 240m, 300m, 360m, 1000m, 3000m

Standard specification: 0.012mm * 0.64m * 120m

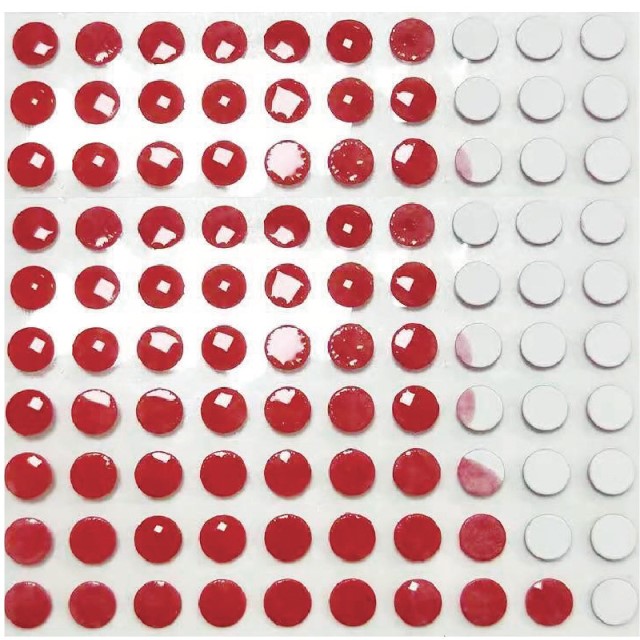

2. Colors: Gold, Silver, Red, Green, Blue, Black, Bronze, Coffee, Matte Gold, Matte Silver, Pearl, Laser, Pigment Foil, etc

3. Type: 1. Sheet 2. Over plastic type 3. Non adhesive type 4. Spray 5. Water pine paper 6. Pigment type 7. Pearl type 8. Hot cloth type

4. Application scope: Suitable for hot stamping various gift packaging boxes, food packaging boxes, tobacco and alcohol packaging boxes, labels, red envelopes, couplets, spring couplets, red envelopes, holiday greeting cards, invitation cards, festive supplies, calendars, written binding tags, trademarks, cosmetics lids, cosmetics hoses, handbags and other paper boxes as well as stationery

5. Hot stamping on various types of paper or cardboard, laminated paper, and plastics such as PC, PS,PP,PET,PVC,OPP,ABS, Imitation leather, etc

6. Product features: clear and beautiful patterns, bright colors, dazzling, wear-resistant, weather resistant, clear contours, suitable for fine patterns, large, medium and small area hot stamping, flat hot stamping and rolling hot stamping, as well as manual, semi-automatic, fully automatic and other hot stamping machines

7. Weight: Gross weight: 1.7KG/roll Net weight: 1.5KG/roll

8. Outer box size: according to customer requirements

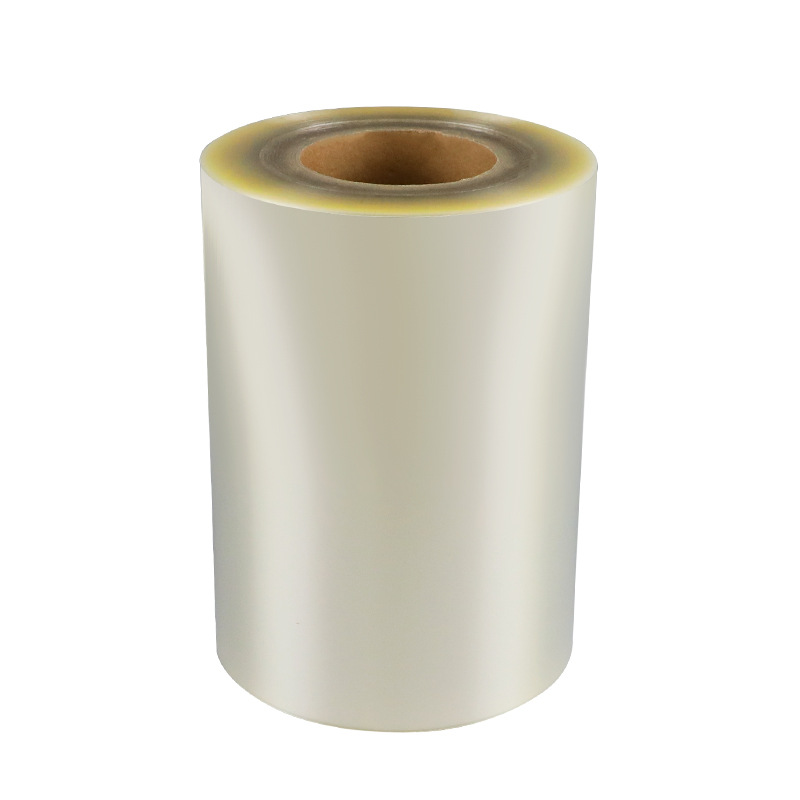

9. Packing list: Inner packaging: PET packaging film Outer packaging: 15 standard rolls per box in cardboard boxes

10. Reference hot stamping temperature: Paper type/Over molded type/Spray type/Non adhesive type/Water pine paper type/Pigment type/Pearl type: 100 ℃ -130 ℃, Hot cloth type: 80 ℃ -145 ℃

11. Reference hot stamping time: 0.3S-0.8S

12. Storage conditions: anti pressure, moisture-proof, heat-resistant, sun proof, stored in a cool and ventilated place, with a shelf life of two years

Can PET material hold food

-

PET is a safe, food-grade plastic. As long as it is not used to store excessively hot liquids or liquids contaminated with oil and dirt that make it difficult to clean, it is suitable for holding drinking water. PET is a very safe food-grade plastic, but it should not be used for storing overly hot or oily liquids, as this can make it difficult to clean thoroughly.

-

Most beverage bottles on the market are made of PET, which is a type of polymer material widely used in various food packaging. These materials are non-toxic and odorless at low temperatures, and even when used to store beverages, they will not have any impact on humans. However, if PET is exposed to high temperatures or sunlight for a long time, it will slowly degrade and release some harmful solvents to the human body.

-

Regardless of the type of plastic product, various additives such as light stabilizers and smoothing agents must be added during the production process. These chemical components are toxic to the human body. If plastic bottles are used to store rice, flour, drinking water, oil, and other substances for a long time, they may dissolve some harmful substances and introduce them into the human body. Additionally, mineral water bottles or beverage bottles should not be reused, as bacteria may easily grow inside them. Therefore, it is recommended to use materials such as glass or stainless steel, which are safer.

PET self-adhesive label

PET is a fibrous material with good rigid ductility, capable of withstanding certain high temperatures, enduring harsh environments, and resisting corrosion from strong acids, strong bases, and other chemicals. Commonly used fabrics include matte silver, matte white, shiny silver, pure white, and fully transparent.

The temperature resistance range of basic PET labels is -20℃ to +120℃, with a minimum label application temperature of 10℃;

For PET labels with strong adhesion used on cables, the temperature resistance range is -20℃ to +100℃, with a minimum label application temperature of 10℃.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.