The Significance of Sterilization Indicator Cards in the Sticker Label Industry

In the ever-evolving world of healthcare and pharmaceuticals, ensuring the safety and effectiveness of medical instruments and devices is of paramount importance. Sterilization indicator cards, an integral component of the quality control process, have gained immense significance in the sticker label industry. These indicator cards play a pivotal role in maintaining the integrity and sterility of medical products. This article delves into the key aspects of sterilization indicator cards, their importance, and their applications within the sticker label industry.

Understanding Sterilization Indicator Cards

Sterilization indicator cards are specialized tools that are used to monitor and verify the effectiveness of sterilization processes. These processes are crucial in healthcare and other industries to eliminate microbial contaminants and ensure that medical instruments, equipment, and products are safe for use. The primary purpose of sterilization indicator cards is to change color when exposed to specific sterilization conditions, indicating whether the sterilization process has been successful.

Importance in the Healthcare Industry

In the healthcare sector, where precision and reliability are non-negotiable, sterilization indicator cards are indispensable. They provide an immediate and visual confirmation of sterilization success or failure. This is particularly critical when dealing with surgical instruments, medical devices, and pharmaceutical products that must be free from harmful microorganisms.

When healthcare professionals use sterilization indicator cards, they can trust that the products they are using have gone through a successful sterilization process. This trust is essential in preventing infections, ensuring patient safety, and maintaining the integrity of healthcare facilities.

Applications in the Sticker Label Industry

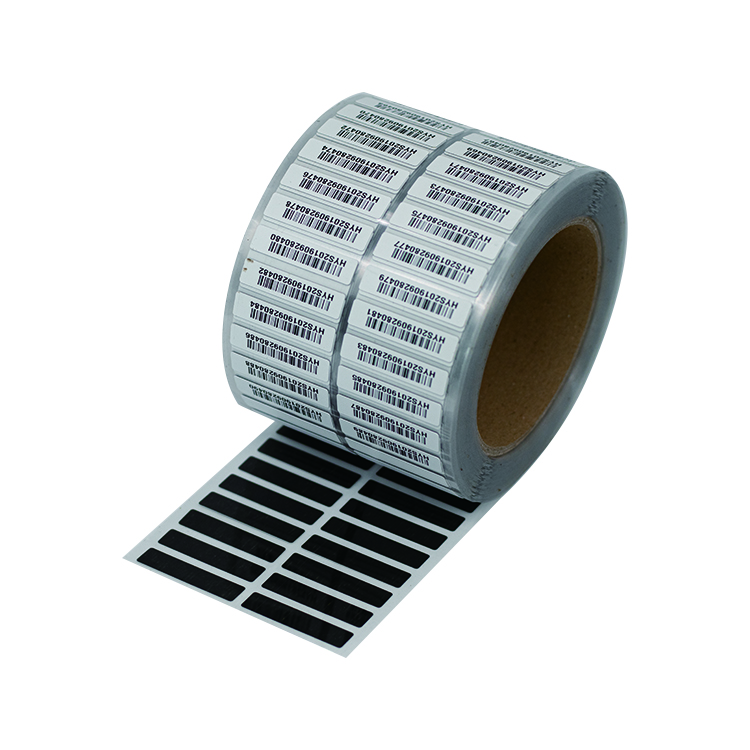

The sticker label industry has also recognized the significance of sterilization indicator cards, particularly in the production of labels for medical equipment and devices. These labels often include information related to usage instructions, product specifications, and sterilization requirements. For products that require sterilization, the inclusion of sterilization indicator cards on the labels has become a standard practice.

Sterilization indicator cards included on sticker labels serve as a visual assurance for end-users. They can quickly determine whether the product they are about to use has been adequately sterilized, giving them confidence in the product's safety and effectiveness. The integration of these indicator cards into sticker labels has revolutionized quality control within the sticker label industry.

The Mechanism of Sterilization Indicator Cards

The functioning of sterilization indicator cards is relatively straightforward. These cards contain a specially designed ink or dye that is sensitive to the conditions of the sterilization process. When exposed to the appropriate conditions, such as heat, steam, or chemicals, the ink or dye reacts and changes color. The change in color is a clear and immediate visual indicator that the sterilization process has been successful. On the other hand, if the process fails to meet the required conditions, the color change does not occur, signaling a potential issue with sterilization.

Benefits of Sterilization Indicator Cards

There are several key advantages to using sterilization indicator cards in the sticker label industry:

- Reliability: Sterilization indicator cards offer a highly reliable and instantaneous method of confirming sterilization success, reducing the risk of using non-sterile products.

- Convenience: These cards are easy to incorporate into sticker labels, making them a convenient solution for manufacturers.

- Cost-Effective: Sterilization indicator cards are a cost-effective way to enhance product safety and quality.

- Compliance: Their use ensures compliance with industry regulations and standards, which is particularly crucial in healthcare and pharmaceuticals.

Conclusion

In the sticker label industry, the integration of sterilization indicator cards has become a game-changer. These cards offer a simple yet effective way to confirm the sterilization status of medical products. The immediate visual feedback they provide not only enhances product safety but also builds trust among end-users.

As the healthcare and pharmaceutical industries continue to advance, the sticker label industry's commitment to quality control, including the use of sterilization indicator cards, remains steadfast. With these cards as an integral part of their products, sticker label manufacturers contribute to safer healthcare practices and improved patient outcomes.

Ultimately, sterilization indicator cards have transcended their role in healthcare to become a vital component of the sticker label industry, where product quality, safety, and compliance are paramount.

For the sticker label industry, and for the broader healthcare community, sterilization indicator cards have proven to be a small yet significant step towards ensuring the highest standards of quality and safety.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.