Sterilization Instruction Label Introduction

Sterilization instruction labels play a pivotal role in various industries, ensuring the safety and efficacy of medical devices, pharmaceutical products, and many other items that require sterilization. These labels serve as essential guides for users and manufacturers alike, providing clear and concise information on how to properly sterilize and maintain the integrity of sensitive equipment and products.

The Importance of Sterilization Labels

Accurate sterilization is crucial in industries such as healthcare, pharmaceuticals, and food processing, where the presence of harmful microorganisms can pose significant risks to public health. Sterilization labels serve several vital purposes:

1. **Safety**: Sterilization labels help ensure that medical equipment and instruments are free from harmful microorganisms, reducing the risk of infections in healthcare settings.

2. **Quality Control**: Manufacturers use sterilization labels to verify that their products have undergone proper sterilization procedures, maintaining product quality and compliance with regulatory standards.

3. **User Guidance**: These labels provide clear instructions to end-users on how to maintain sterility and avoid contamination, guaranteeing product effectiveness.

Components of Sterilization Labels

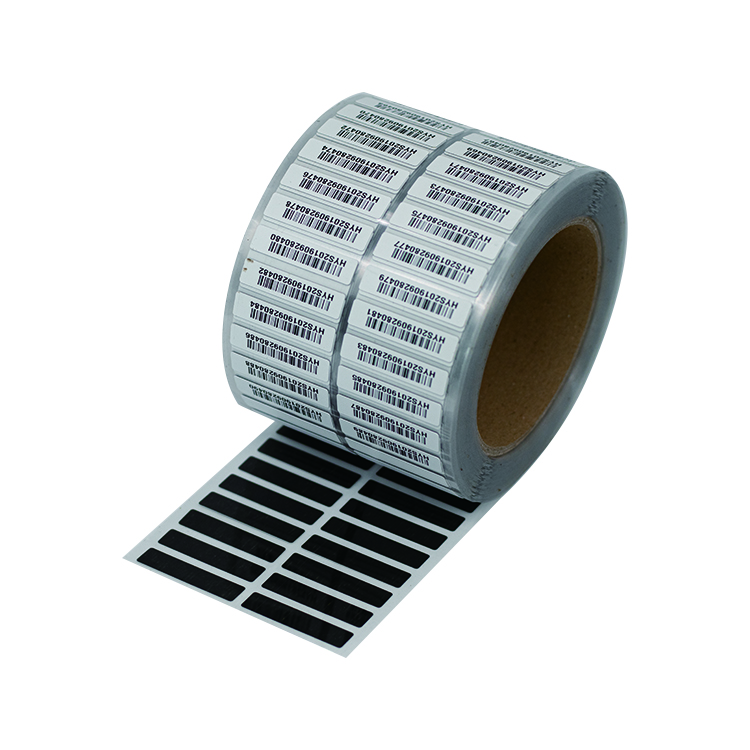

Sterilization labels typically consist of the following components:

1. **Identification Information**: This includes the product name, lot number, and expiration date to trace and verify the product's origin and lifespan.

2. **Sterilization Method**: Clear indication of the sterilization method used, such as steam, ethylene oxide, or radiation.

3. **Instructions for Use**: Detailed instructions on how to properly sterilize the product, including recommended temperature, pressure, and duration.

4. **Cautionary Symbols**: Universal symbols or text highlighting precautions, such as "Do Not Reuse" or "Handle with Care."

5. **Barcodes**: Barcodes for quick and accurate tracking, especially in healthcare settings.

Common Sterilization Methods

Various sterilization methods are used in different industries, each with its advantages and limitations:

1. **Autoclaving**: Utilizes high-pressure steam to kill microorganisms and is commonly used in healthcare and laboratories.

2. **Ethylene Oxide (EO) Sterilization**: Suitable for heat-sensitive items and medical devices, as it doesn't involve high temperatures.

3. **Gamma Radiation**: Effective in sterilizing a wide range of products, including pharmaceuticals and certain medical devices.

4. **Chemical Sterilization**: Uses chemical agents like hydrogen peroxide to sterilize sensitive equipment.

5. **Dry Heat Sterilization**: Effective for items that can withstand high temperatures without moisture, like glassware and metal instruments.

Regulatory Compliance

Sterilization labels must adhere to industry-specific regulations and standards, ensuring safety and quality. Regulatory bodies like the FDA (Food and Drug Administration) and ISO (International Organization for Standardization) set guidelines for labeling practices. Compliance with these standards is essential to prevent recalls, ensure patient safety, and maintain the reputation of manufacturers.

Conclusion

In conclusion, sterilization instruction labels are indispensable tools in various industries where sterilization is critical. They provide essential information to manufacturers, healthcare professionals, and end-users, ensuring that products remain safe and effective. By following the instructions on these labels and adhering to regulatory standards, industries can maintain high levels of quality and safety, ultimately benefiting public health and product integrity.

For more information on specific sterilization practices and regulations, it is advisable to consult industry-specific guidelines and standards.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.