Classification of sterilization indicator cards

-

Process chemical indicator card: Used for individual items or packages to indicate whether the item has undergone a sterilization process, distinguishing between sterilized and non-sterilized items, such as chemical indicator tape.

-

Special test chemical indicator card: Used for specific experimental operations related to sterilizers or sterilization standards, such as various B-D test papers. It detects the effectiveness of cold air removal and saturated steam penetration in pre-vacuum sterilizers, as well as any air leaks.

-

Single-parameter chemical indicator card: Used for testing a single parameter during the sterilization process, such as gas concentration indicator cards (e.g., hydrogen peroxide low-temperature plasma).

-

Multi-parameter chemical indicator card: Features two or more key parameters (time, temperature, humidity, gas concentration, steam saturation level).

-

Comprehensive parameter chemical indicator card: A specialized indicator card that reacts to all parameters within the specified range during various sterilization processes, with set values reaching the inactivation level.

-

Simulated chemical indicator card: An indicator card that reacts to all evaluation parameters within the specified range of each sterilization cycle, with set values based on the selected sterilization program settings.

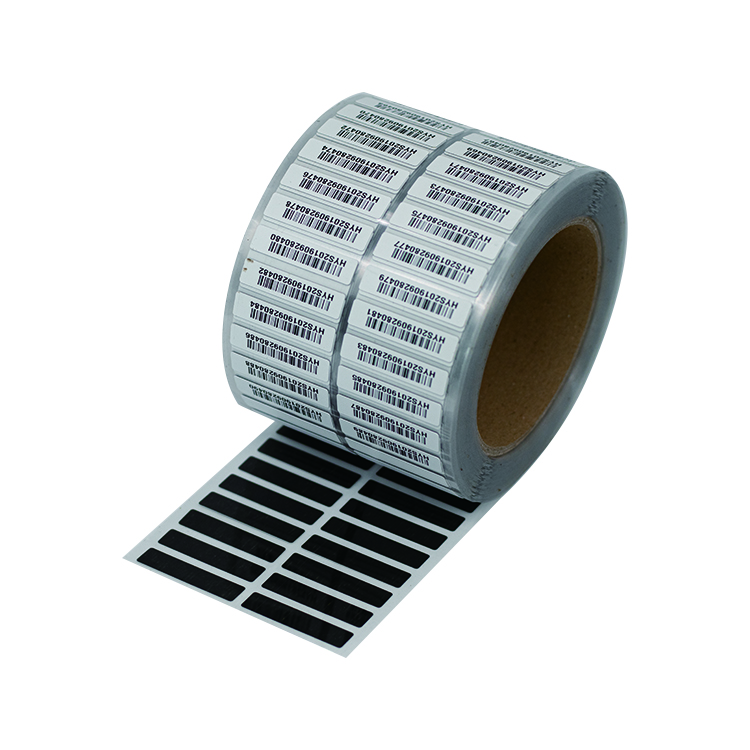

Low temperature plasma sterilization indicator label/card/tape

Apply thermosensitive chemical color changing ink as a sterilization indicator, and back coat with pressure-sensitive adhesive release paper. It can be used inside item packaging or attached to the surface of the sterilization package. Under the required sterilization conditions, the color of the indicator color code changes from red to yellow, and the color after sterilization is not easily faded

Instructions for use

1. Remove the plasma sterilization indicator label from the backing paper and directly stick it to the surface of the sterilized item package. Gently press the label to enhance its sealing effect, and then place it in the plasma sterilizer for sterilization treatment

2. After sterilization, take out the package and observe the color change of the indicator label. If the label changes from red to yellow, it indicates that the package has been sterilized; If the label color remains unchanged, it indicates that the package has not undergone sterilization treatment

Suitable for hospitals, pharmaceuticals, food, health products, beverages, hygiene and epidemic prevention, medical device manufacturers, and sterilization service institutions to perform plasma sterilization, used to indicate whether the sterilization package has undergone plasma sterilization treatment, and also used for plasma indicator effect detection and judgment

Gamma Cobalt 60 Sterilization Indicator Label

Coated with thermosensitive chemical color changing ink as a sterilization indicator, and backed with pressure-sensitive adhesive release paper, it can be used inside item packaging or attached to the surface of the sterilization package. Under the sterilization conditions of gamma cobalt 60Co gamma electron beam radiation, the color of the indicator color code changes from yellow to red, and the color after sterilization is not easily faded.

Cobalt-60 sterilization is the process of using 60Co gamma rays to irradiate microorganisms, directly or indirectly damaging their nuclei, thereby killing microorganisms and achieving disinfection and sterilization. It is a type of irradiation sterilization technology that uses V-rays generated by the radioactive isotope cobalt-60 to irradiate packaged food. In the process of energy transmission and transfer, strong and enhanced physical and biological effects are generated to achieve the goals of insecticide, sterilization, inhibition of physiological processes, food hygiene quality, maintenance of nutritional quality and flavor, and extension of shelf life

Suitable for hospitals, pharmaceuticals, food, health products, beverages, hygiene and epidemic prevention, medical device manufacturers, and sterilization service institutions to sterilize gamma cobalt-60 electron beam, used to indicate whether the sterilization package has undergone plasma sterilization treatment, and also used for gamma cobalt-60 indicator effect testing and judgment

Radiation sterilization instruction label

The irradiation sterilization color-changing indicator label is a circular label with a diameter of 13mm, used as an indicator for whether irradiation sterilization products have been exposed and whether the dose has reached the required level. Compared to similar types of indicator labels, its larger diameter makes it more eye-catching and easier to identify.

Before irradiation sterilization, the yellow label is attached to the outer packaging of the product. After the irradiation dose reaches the corresponding requirement, it changes to a bright red color. The color starts to change at 4kGy, and as the dose increases, the red color gradually deepens.

There are 5000 labels per roll, and customized production is also available according to user requirements.

Requirements for sterilization labeling

The requirements for sterilization markings include the form, location, and content of the markings.

-

Form of markings: Sterilization markings typically appear in the form of graphics, text, or symbols to clearly indicate that the product has been sterilized.

-

Location of markings: Sterilization markings should be clear, easily identifiable, and placed in a visible location on the product packaging or container to ensure that consumers can easily see them.

-

Content of markings: Sterilization markings should include relevant information such as the sterilization method, date, batch number, etc., to provide information about the product's sterilization process.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.