How to Apply Strong Adhesive Oil Resistant Labels: A Comprehensive Guide to the Sticker Label Industry

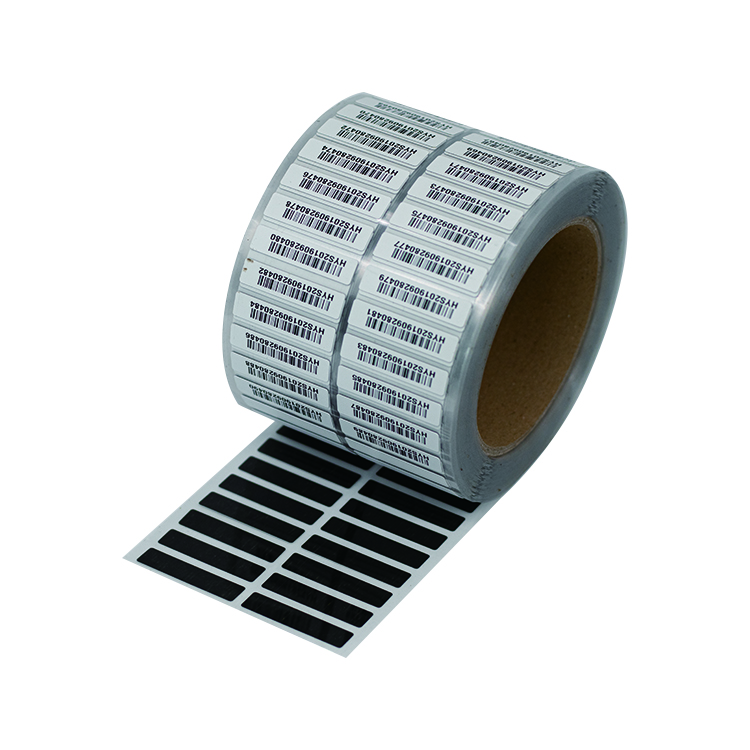

Sticker labels have become indispensable in various industries, providing essential information and branding for products. One critical aspect of sticker labels is their adhesive strength and resistance to oil, ensuring they remain affixed and readable even in challenging environments. In this comprehensive guide, we will explore the techniques and considerations involved in applying strong adhesive oil-resistant labels.

Understanding the Basics of Strong Adhesive Oil-Resistant Labels

Before delving into the application process, it is crucial to comprehend the fundamental characteristics of strong adhesive oil-resistant labels. These labels are specifically engineered to adhere firmly to surfaces while withstanding exposure to oil, ensuring longevity and readability in industrial settings.

Selecting the Right Label Material

Choosing an appropriate label material is the first step in ensuring the effectiveness of strong adhesive oil-resistant labels. Materials like polyester and vinyl offer excellent durability and oil resistance, making them ideal choices for applications in challenging environments.

Preparation of Surfaces

Proper surface preparation is essential for the adhesive to bond effectively. Surfaces must be clean, dry, and free from any contaminants such as oil, dust, or moisture. Utilizing cleaning solutions designed for specific surfaces can enhance the adhesion of the labels.

Application Techniques

The application technique plays a significant role in the longevity of sticker labels. Applying consistent pressure, using appropriate tools like squeegees, and ensuring uniformity during application are key factors. Additionally, following the manufacturer's guidelines regarding temperature and pressure conditions is vital for optimal adhesion.

Quality Assurance and Testing

Quality assurance measures are imperative to guarantee the effectiveness of strong adhesive oil-resistant labels. Regular testing, both in controlled environments and real-world conditions, helps assess the labels' performance over time. Conducting tests related to oil exposure, temperature variations, and abrasion resistance provides valuable insights into the labels' durability.

Conclusion

In conclusion, the application of strong adhesive oil-resistant labels requires meticulous attention to detail and adherence to best practices. By understanding the fundamentals, selecting the right materials, preparing surfaces adequately, employing proper application techniques, and conducting thorough quality testing, industries can ensure the labels remain intact and legible in oil-prone environments. Following these guidelines will undoubtedly enhance the efficiency and effectiveness of sticker labels in various applications.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.