What is a self-adhesive label

adhesive labels are composite materials made of film, paper, or special materials, with adhesive coated on the back and silicone coated paper as protective paper. They are processed through printing, die-cutting, and other techniques to create finished labels. When in use, simply peel off from the base paper and press lightly to apply it to the surface of various substrates. It can also be automatically labeled on the production line using a labeling machine.

Compared with traditional labels, self-adhesive labels do not require glue brushing, paste, or pollution, which can save labeling time and be easily and quickly applied in various situations. Various types of labels can be processed using different fabrics, adhesives, and base paper, and applied to materials that cannot be used for general paper labels. It can be said that adhesive labels are a universal label.

Classification of self-adhesive labels

Adhesive labels can be basically divided into two categories: paper adhesive labels and film adhesive labels.

Paper adhesive labels include transfer printing labels, regular paper labels, thermal sensitive labels, special labels, and anti-counterfeiting labels;

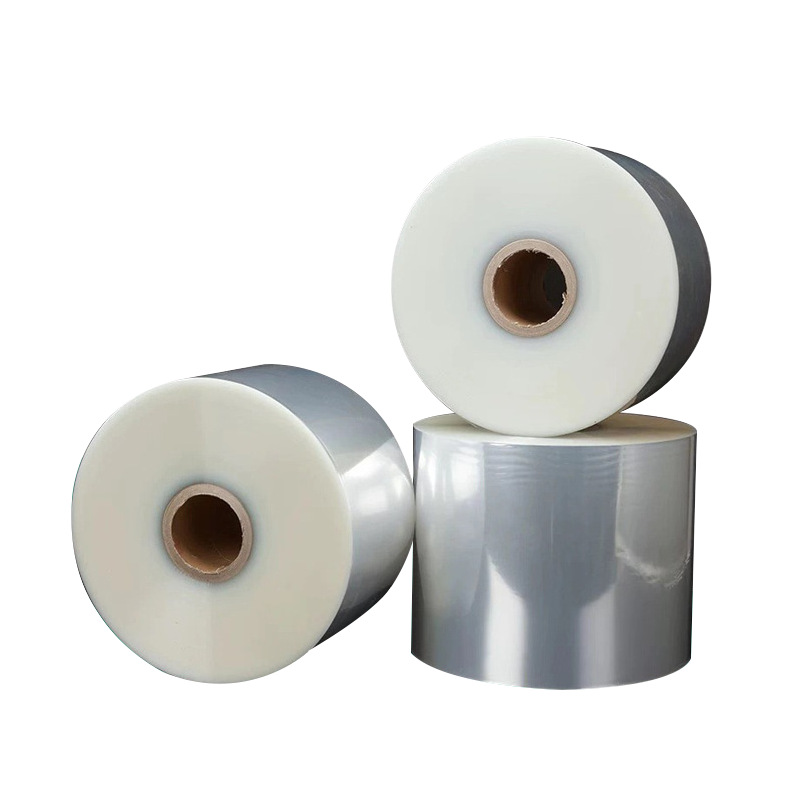

Film labels include polyethylene film (PE), PP (polypropylene) adhesive labels, PET (polypropylene) adhesive labels, PVC shrink film adhesive labels, etc.

Compared with traditional stickers, self-adhesive stickers

Compared with traditional stickers, self-adhesive stickers have the advantages of no brushing, no paste, no dipping in water, no pollution, saving labeling time, etc. They are widely used, convenient and fast. All kinds of self-adhesive labels can be applied to materials that are not suitable for ordinary paper labels. It can be said that self-adhesive labels are universal labels. The printing of self-adhesive labels is very different from the printing of traditional printed materials. The self-adhesive labels are usually printed and processed on the labeling machine, and multiple processes are completed at one time, such as graphic printing, die-cutting, waste disposal, sheet cutting and rewinding. It can be seen that self-adhesive labels have high requirements for printing technology and printing equipment. Therefore, when choosing self-adhesive labels, several points should be noted:

⑴ Consider comprehensively based on the type, grade, quality, characteristics of the adhesive surface, usage environment, and user requirements of the labeled object. If a label made of transparent polypropylene adhesive is applied to a transparent bottle, it can create a fashionable feeling without a label, improve the quality of the product, and stimulate consumers' desire to purchase. The flexibility, shrinkage, opacity, processing characteristics, and labeling properties of polyvinyl chloride film are very good, and the colors are bright and the contrast is large, which can attract people's attention and have the effect of promoting and selling products

The surface of thin film adhesive labels must be smooth, dense, uniformly dense, consistent in color, and have good transparency to ensure uniform ink absorption of the film and small color difference of the same batch of printed products

The thickness of the adhesive label should be uniform, and the strength index should be qualified. The printing pressure applied during the printing process is related to the thickness of the adhesive. If the thickness is uneven, the printing pressure will also be uneven, which can cause the handwriting or ink color of the printed label to be dark or light. If the film strength is too poor, the tension of the film during the printing process will be difficult to control, which will have a significant impact on die-cutting and waste disposal

The adhesive label should be flat and the rewinding tension should be even. Good flatness is necessary for correct conveying, operation, alignment, and winding during printing. The rewinding tension of the film should be uniform and appropriate. If the tension is too low, the film substrate may become loose, and the longitudinal and transverse overprinting may not be accurate; If the tension is too high, the substrate will shrink laterally, the color matching will be unstable, and it will be difficult to print normally

Membrane adhesive labels should also have the characteristics of corrosion resistance, aging resistance, non fading, and low shrinkage and expansion ratios. If the corrosion resistance is poor, prone to aging and fading, the label produced will not be durable and will also affect the sales and use of the product. If the shrinkage and expansion ratio is large, it not only affects the printing accuracy during printing, but also causes deformation of the label during use, affecting the sales and use of the product. Especially for high-end product labels, efforts should be made to avoid the awkward situation where the product has not expired but the label has already aged (label aging includes reasons such as plastic aging and ink fading). If necessary, aging resistance tests should be conducted on plastics or labels to test their performance

The selected adhesive labels should also be within their validity period and maintain good adhesion

Adhesive thermal label paper

Adhesive thermal label paper is a type of thermal printing paper specifically used for electronic scales and cash registers, and should be used in conjunction with label printers or thermal printers. Long term exposure to sunlight and high working temperatures can accelerate the fading of text and images. Thermal label paper on the market is generally divided into ordinary thermal label paper and three proof thermal label paper (waterproof, oil proof, alcohol proof), which can be purchased according to needs

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.