Garbage classification adhesive label stickers

1. When using labels, the label paper should be kept warm (around 20 ℃) so that it can exert maximum adhesion

2. The use of labels should only be applicable in dry weather (i.e. without rain, snow, etc.)

3. Labels should be applied to concrete surfaces with temperatures above 10 ℃

4. Labels should be applied to surfaces suitable for adhesion. The surface suitable for pasting should be smooth, without cracks, holes, and gravel

5. Before pasting, the surface of the object to be pasted should be cleaned first

6. Try to avoid contaminating glue with income and expenses as much as possible

7. After pasting, it is necessary to press the label firmly a few times

Cleaning method for adhesive labels

1. First, tear off the adhesive decorations attached to the glass or product surface, soak the towel in warm water (hot water should be used in winter), and repeatedly wipe the adhesive marks twice; Then use a warm and damp towel with soap, and repeatedly wipe the marks several times; Finally, use a clean and warm towel to wipe off the soap foam, and the adhesive marks will be removed

2. Apply toothpaste evenly on the surface of the sticker, let it sit for a while, and then wipe it with a soft cloth. Sometimes there are more stickers and they are more firm. Just apply toothpaste on the traces that have not been removed in one go. The method is still the same, and you can remove the headache sticker. The principle is that toothpaste contains glycerin, which is a good solvent that can dissolve the components of stickers. In addition, many cosmetics also contain glycerin, which can be used to remove stickers

3. Furthermore, using a pen, paper, or knife to scrape, it is suitable for hard surfaces such as glass and floor tiles; Wipe with alcohol, suitable for glass, floor tiles, clothing, etc; Freezing, once the adhesive becomes hard after freezing, it can be directly peeled off and is suitable for methods that are not suitable for alcohol or scratching

4. I heard that the effect of wind oil essence is also good. If it is a self-adhesive sticker or the like, it can be easily peeled off by blowing it with a hair dryer. However, it is not suitable for plastic, as overheated plastic will deform

5. Using a wind dryer to heat blow is very effective and convenient at home. Almost everyone has a wind dryer, whether it is for sticker glass, plastic, wood, or metal. First, use a wind dryer to heat blow back and forth a few times, then tear a small edge and slowly tear along the direction of tearing while using the wind dryer to heat blow. The effect is very good

6. Rub vigorously with a rubber a few times

7. In industry, wiping with natural water is very easy to remove

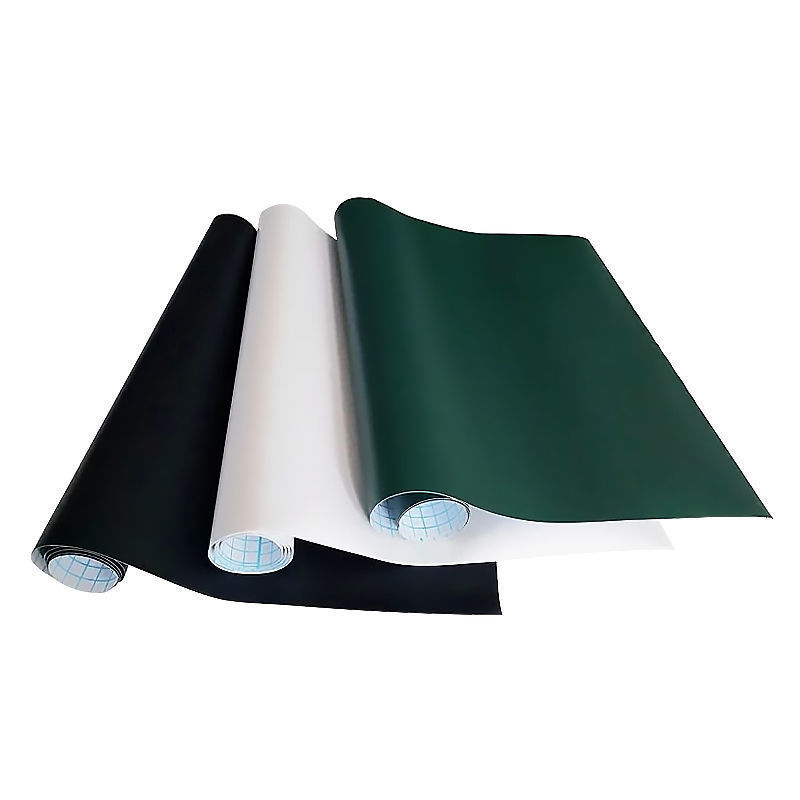

Laser etched adhesive material

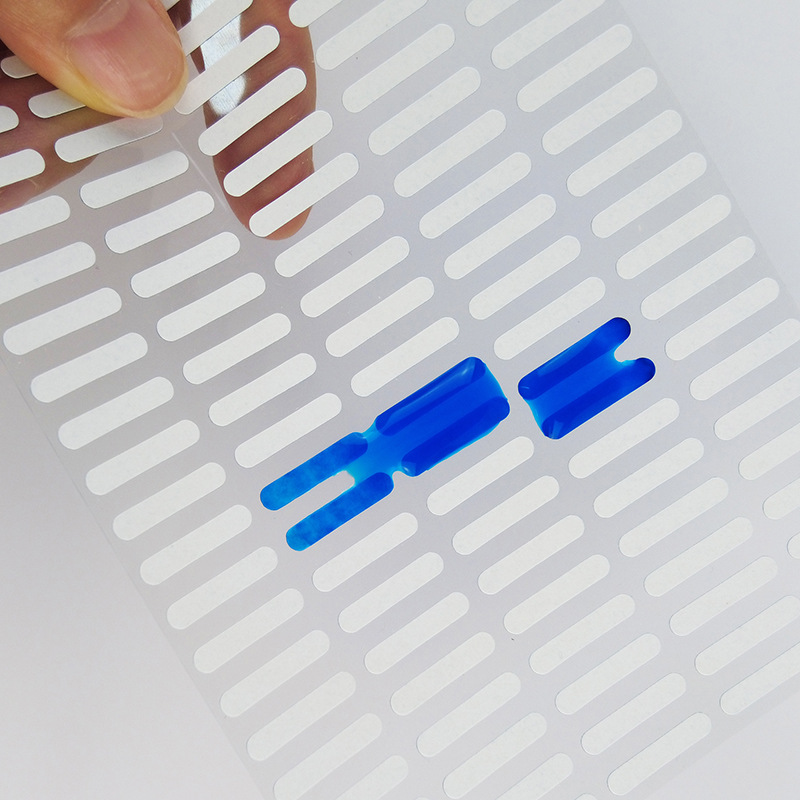

Laser etched label paper is a two-layer film used for the production of labels in laser marking equipment. By special production techniques, the black surface and white bottom form a unified whole. The material is halogen-free and resistant to chemical substances, temperature and other environmental influences. It is coated with high-performance acrylic adhesive, which has good initial adhesion and high final adhesion even on low-energy surface energy surfaces such as polypropylene. Laser label paper can also be used for identifying evidence based on specific application scenarios. Usually, once the label is attached to a surface and removed, it will be damaged and comply with UL/CSA standards

Laser can etch the top layer of double-layer materials to form a certain pattern. The same laser also allows labels to be semi perforated to specific sizes, increasing flexibility to manufacture various durable labels

Surface substrate:

Basic weight: 155g/m2 10% Thickness: 100um 10%

The surface material of this product has been treated to be resistant to chemicals such as engine oil, alcohol, and gasoline, and is suitable for anti-counterfeiting purposes on nameplates. Commonly used for labeling automotive components such as internal combustion engines, VIN codes, and vehicle information plates, disinfecting medical equipment labels, power battery labels, and nameplates for equipment with complex operating conditions

Adhesive:

Initial adhesion force:≥ 20 N 90° Peel force:≥ 9N/25mm

Minimum label temperature: 5 ℃ Operating temperature: -40 ℃ -150 ℃

This product uses modified acrylic adhesive, which has good initial adhesion, adhesion, and temperature resistance. It has excellent adhesion performance on metal surfaces or metal paint surfaces

Release paper:

Basic weight 110g/m2 10% Thickness: 105um 10%

Opacity: 85% Longitudinal tensile strength: 40-55N

Processing Attention:

This product is suitable for laser marking and cutting. Attention should be paid to adjusting the filling method, density, energy, and speed< br /> Storage period: at a temperature of 23 ° C; 2 ° C, relative humidity of 50 ° C; In 5% of cases, it can be stored for one year. Products that have exceeded their expiration date can still be used after passing inspection

Instructions for use:

The temperature resistance, chemical resistance, peel resistance, and wear resistance of the product need to be tested and approved according to the end use scenario before use

Adhesive label printing

Small adhesive labels are often an important reflection of a company's image and brand, playing a crucial role in showcasing product quality and arousing consumer desire to purchase. So, when choosing labels or self-adhesive labels, how can the printing process of self-adhesive labels avoid the occurrence of adhesive residue

1. For cylindrical bottles, especially those with a diameter less than 30MM, careful selection of materials is necessary.

2. If the label size is too large or too small, attention should be paid to conducting actual tests.

3. If the object being pasted is an irregular surface or even a spherical surface, there are specific considerations for the type, thickness, and adhesive of the label material.

4. Some rough surfaces such as corrugated cardboard boxes can affect labeling, and the gloss on the surface of corrugated cardboard boxes can also have an impact.

5. Automatic labeling machine labels, and labeling tests can be conducted if necessary.

6. Even if the label is labeled at room temperature, attention should be paid to whether it has experienced high temperatures during export transportation and use.

7. The characteristics of adhesives can be affected by environments with high water or oil content, and attention should be paid to the environment and temperature for label labeling.

8. Sometimes plasticizers may seep out from the surface of soft PVC, so special attention should be paid to selecting the appropriate adhesive.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.