Steam sterilization instruction label/card/tape

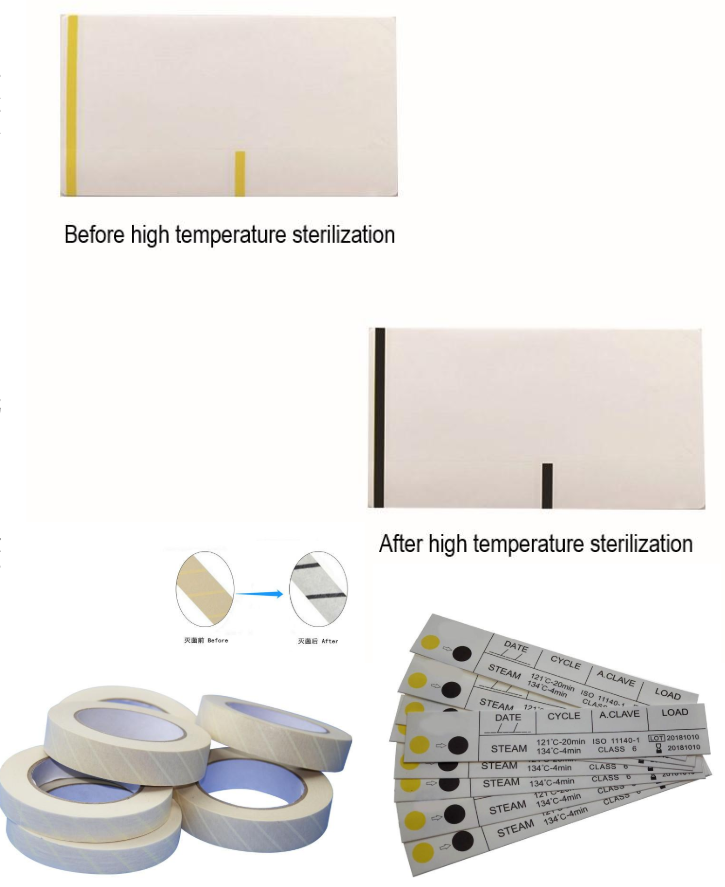

Coated with color changing ink as a sterilization indicator, back coated with pressure-sensitive adhesive release paper, the label is printed with thermosensitive chemical material, which can be used inside the packaging of the item or attached to the surface of the sterilization package. Under the required sterilization conditions, the indicator color code changes from yellow to black, and the color after sterilization is not easy to fade

Instructions for use:

1. Remove the steam ethane sterilization indicator label from the backing paper and directly stick it to the surface of the sterilized item package. Gently press the label to enhance its sealing effect, and then place it in the steam sterilization pot for sterilization treatment

2. After sterilization, take out the package and observe the color change of the indicator label. If the label changes from yellow to black, it indicates that the package has been sterilized; If the label color remains unchanged, it indicates that the package has not undergone sterilization treatment

Suitable for hospitals, pharmaceuticals, food, health products, beverages, hygiene and epidemic prevention, medical device manufacturers, and sterilization service institutions to perform pressure steam sterilization, used to indicate whether the sterilization package has undergone pressure steam sterilization treatment, and also used for steam sterilization indicator effect testing and judgment

Sterilization instruction label

Sterilization indicator label is a special label used to monitor and indicate whether an item has undergone sterilization treatment. It is usually made of corrugated paper or label paper as the substrate, coated with color changing ink as a sterilization indicator, and back coated with pressure-sensitive adhesive. Under the standard conditions of pressure steam sterilization treatment temperature, temperature duration, and steam saturation, the indicator color block of the sterilization indicator label will change color, such as from light yellow to black, to intuitively reflect whether the sterilization result is qualified

The main uses of sterilization indicator labels include:

- Indicate whether the item package has undergone pressure steam sterilization process

- If the discoloration is uneven or incomplete, it may indicate that the package has not undergone sterilization treatment that meets the conditions

- Sterilization information can be recorded, such as the operator, sterilization expiration date, package item name, pot, etc

There are various types of sterilization indicator labels, including single label, roll label, traceable label, etc., which are suitable for different sterilization needs and scenarios. In addition, with the continuous development of medical technology, the performance and types of sterilization indicator labels are also constantly updated and improved to meet a wider range of sterilization monitoring needs

The function of sterilization indicator labels

Sterilization indicator labels play a crucial role in various fields such as healthcare, biological experiments, and food processing. Its core role is mainly reflected in the following aspects:

- Intuitive display of sterilization status: The sterilization indicator label can clearly and intuitively display whether the item has undergone the prescribed sterilization process through color changes.. This helps staff quickly assess the safety of items and avoid using unsterilized or incompletely sterilized items

- Ensure sterilization quality: The discoloration of the label is a direct reflection of the sterilization effect. If the label changes color unevenly or does not change color, it indicates that there may be problems with the sterilization process, such as temperature, time, or steam saturation not meeting the requirements. This prompts staff to inspect and improve the sterilization process to ensure sterilization quality

- Recording and Traceability: Some sterilization indicator labels also have the function of recording sterilization information, such as operator, sterilization date, expiration date, etc. This helps establish a traceability system for sterilized items, improving management efficiency and safety

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.