Sustainability Considerations in Flame Retardant Label Technology

Introduction:

Sticker labels play a crucial role in various industries, providing essential information, branding, and identification. However, the production and disposal of sticker labels can have significant environmental impacts. In recent years, there has been a growing focus on sustainability within the label industry, prompting the development of flame retardant label technology. This article explores the sustainability considerations associated with flame retardant label technology and its potential benefits.

Flame Retardant Label Technology: An Overview

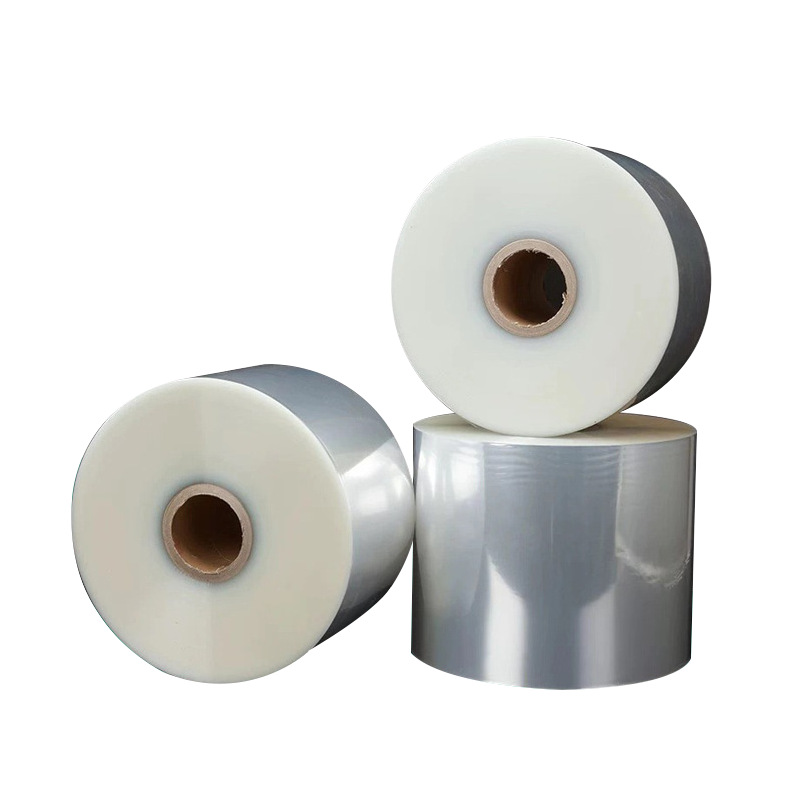

Flame retardant label technology involves the use of materials and manufacturing processes that reduce the flammability of labels. These labels are designed to resist ignition, slow down flame spread, and self-extinguish when exposed to fire. The incorporation of flame retardant properties into sticker labels enhances safety measures in various applications, including electrical equipment, automotive, and consumer goods.

The Environmental Impact of Traditional Labels

Traditional sticker labels often contain materials that are not environmentally friendly. For instance, some labels are made from non-recyclable plastics, which contribute to the growing problem of plastic waste. Moreover, the production of these labels involves energy-intensive processes and the emission of greenhouse gases. Additionally, when traditional labels are disposed of, they can end up in landfills, further exacerbating environmental concerns.

Sustainability Benefits of Flame Retardant Label Technology

1. Enhanced Safety:

Flame retardant label technology significantly improves safety standards. By reducing the flammability of labels, the risk of fire-related accidents can be minimized. This is particularly crucial in industries where flammable materials or high temperatures are present.

2. Reduced Environmental Impact:

Flame retardant labels offer a more sustainable alternative to traditional labels. These labels can be manufactured using environmentally friendly materials such as bio-based polymers or recycled paper. By choosing sustainable materials, the label industry can contribute to reducing plastic waste and greenhouse gas emissions.

3. Recycling and Reusability:

Flame retardant labels can be designed for easy recycling. By using recyclable materials and incorporating appropriate labeling, the recycling process can be streamlined. Additionally, these labels can also be designed for reusability, allowing them to be removed and applied to other products, reducing waste generation.

Challenges and Future Considerations

Despite the numerous benefits, flame retardant label technology also presents some challenges. For instance, the development of cost-effective and efficient manufacturing processes for these labels is crucial. Furthermore, ensuring the compatibility of flame retardant labels with existing labeling equipment and standards is essential for widespread adoption.

In the future, it will be important to continue research and development efforts to improve the sustainability of flame retardant label technology. This includes exploring new materials, optimizing manufacturing processes, and establishing industry-wide standards for eco-friendly labels.

Conclusion

Flame retardant label technology offers a sustainable solution for the label industry, addressing both safety and environmental concerns. By incorporating flame retardant properties into labels, the risk of fire-related accidents can be reduced, while the environmental impact of production and disposal can be minimized. The adoption of this technology can contribute to a more sustainable and responsible label industry, paving the way for a greener future.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.