Classification of sterilization indicator cards

-

Process chemical indicator card: Used for individual items or packages to indicate whether the item has undergone a sterilization process, distinguishing between sterilized and non-sterilized items, such as chemical indicator tape.

-

Special test chemical indicator card: Used for specific experimental operations related to sterilizers or sterilization standards, such as various B-D test papers. It detects the effectiveness of cold air removal and saturated steam penetration in pre-vacuum sterilizers, as well as any air leaks.

-

Single-parameter chemical indicator card: Used for testing a single parameter during the sterilization process, such as gas concentration indicator cards (e.g., hydrogen peroxide low-temperature plasma).

-

Multi-parameter chemical indicator card: Features two or more key parameters (time, temperature, humidity, gas concentration, steam saturation level).

-

Comprehensive parameter chemical indicator card: A specialized indicator card that reacts to all parameters within the specified range during various sterilization processes, with set values reaching the inactivation level.

-

Simulated chemical indicator card: An indicator card that reacts to all evaluation parameters within the specified range of each sterilization cycle, with set values based on the selected sterilization program settings.

Disinfection and sterilization indicator tape

Sterilization indicator tape is a product used to indicate the sterilization process. It utilizes indicator ink on the tape that changes color after undergoing sterilization, allowing for the determination of whether an item has been sterilized or not. This provides a straightforward and convenient way to assess the sterilization status of the item.

Commonly used sterilization methods include high-pressure steam sterilization, ethylene oxide sterilization (EO sterilization), and plasma sterilization.

Medical sterilization indicator tape is a product specifically designed for the medical field to indicate the sterilization process. It utilizes indicator ink on the tape that changes color after undergoing sterilization, enabling the determination of whether a medical item has been sterilized or not. This provides a straightforward and convenient means of reflecting the sterilization status of the medical item.

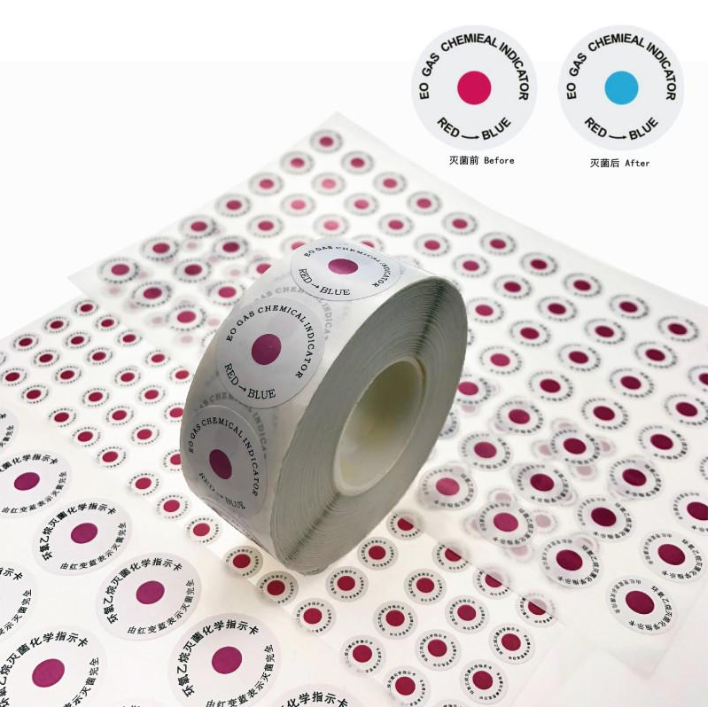

EO ethylene oxide sterilization indicator sticker/card/tape

The principle of EO ethylene oxide sterilization purple to blue indicator label is that it undergoes alkylation reaction with thiol groups (- SH), amino groups (- NH2), hydroxyl groups (- OH), carboxyl groups (- COOH) on protein molecules, as well as amino groups (- NH -) on nucleic acid molecules, causing the protein to lose reactive groups, hindering the normal biochemical reaction and metabolism of the protein and leading to microbial death, thereby achieving sterilization effect.

When using ethylene oxide sterilization gas for sterilization, the temperature, humidity, concentration of sterilization gas, and sterilization time inside the sterilization cabinet are important parameters that affect the sterilization effect. Due to the potential carcinogenicity, mutagenicity, and acute toxicity of ethylene oxide, it is necessary to closely monitor the atmospheric concentration, chamber temperature and humidity, pressure, ethylene oxide gas concentration, and sterilization time during the sterilization process for the safety of personnel. The sterilization effect is usually monitored using biological EO ethylene oxide sterilization indicator labels. The control of sterilizers is somewhat difficult, and the entire sterilization process should be carried out under the supervision of skilled technicians. After sterilization treatment, filtered sterile air should be introduced and undergo a vacuum air circulation process to safely remove residual ethylene oxide.

Suitable for hospitals, pharmaceuticals, food, health products, beverages, hygiene and epidemic prevention, medical equipment manufacturers, and sterilization service institutions to sterilize with ethylene oxide. It is used to indicate whether the sterilization package has undergone ethylene oxide sterilization treatment, and also to test and judge the effectiveness of ethylene oxide sterilization.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.