Ceramic barcode for liquefied gas cylinder

Liquefied gas cylinder ceramic barcode is a barcode label generated by high-temperature glaze firing on a high-strength alumina engineering ceramic substrate. The barcode symbol is well protected by transparent high-temperature glaze, and the ceramic barcode can withstand extremely harsh environments such as acid, alkali, salt, fog, sunlight exposure, and even flame grilling for a long time. The excellent performance of liquefied gas cylinder barcodes precisely meets the requirements of permanent automatic identification and labeling of gas cylinders. The basic situation of existing commercialized ceramic barcode gas cylinder identification signs that have been tested for batch durability is as follows:

1. Matrix material: high-purity Al2O3 industrial ceramics

2. Surface glaze material: transparent glaze

3. The size and shape of the label can be customized according to user requirements

4. Barcode parameters: one-dimensional barcode, two-dimensional barcode, barcode format, size, resolution and other technical parameters can be customized according to user requirements

5. High temperature resistance (up to 1200 ° C or above), acid, alkali, salt, and mist corrosion resistance, and resistance to organic solvent scrubbing.

6. Resistant to vibration and impact, with good mechanical strength

7. The text information on the surface of porcelain tiles is not easy to scratch and never fades, truly becoming a permanent barcode for use

High temperature resistant aluminum foil hang tag

High temperature resistant hang tag is an aluminum foil coated with high-temperature resistant coating, mainly developed for the growing demand of customers in the steel industry for product traceability. It is specifically used on steel and aluminum molded parts. This material can resist the influence of surrounding factors such as climate and industrial environment, such as oil pollution, emulsifiers, acid and alkali erosion, as well as the impact of harsh weather conditions such as wind, rain, lightning and ultraviolet rays during transportation and storage, ensuring excellent performance in various extreme and harsh application environments. In order to ensure smooth waste discharge, suitable die-cutting knives should be specially selected for processing

Suitable for high-temperature industrial applications. Because of its high initial viscosity and final viscosity, it can be adhered to various substrates, including metal sheets with medium and low energy

Product Parameters

Coating: White

Thickness: 80 ml

Substrate: Aluminum

Temperature resistance range -40 ° C; C-600° C labeling temperature: 250 ℃ C-300 ℃

Product Features

Maximum resistance to high temperature of 600 ℃

Tensile, tear, and friction resistance

Resistant to strong acids and other chemical reagents

No need for cooling, directly heat apply

Can be directly printed by a heat transfer label printer

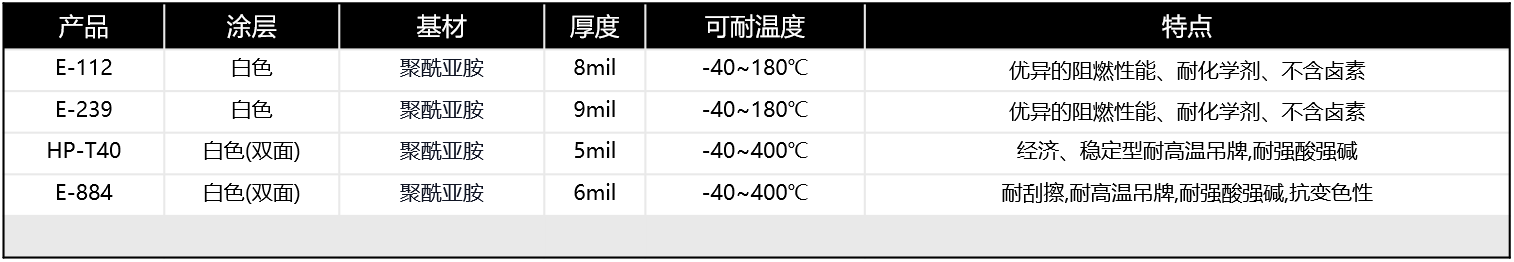

High temperature resistant polyimide tag material

High temperature resistant polyimide tags are used in extremely harsh production environments for steel, aluminum, and their castings. They can be applied in heat treatment production operations and hung on products as tags for production management and traceability. They have good resistance to deformation, solvents, and high temperatures

Application

Production management, traceability

Steel wire, steel coil, steel block

Aluminum products, stainless steel

Special steel tempering and annealing

High pressure gas cylinder

Automotive Parts

Inventory management, process management

Features and Advantages

Multiple materials and different thicknesses< br /> High cost-effectiveness

Excellent printing and printing effect

Can withstand 300 degrees Celsius; C high temperature

Acid resistant and suitable for open flames

Resistant to chemicals, moisture, and dirt

Economic and stable high-temperature resistant steel hang tag

High temperature resistant steel tag material list

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.