Removable high temperature label

Removable high-temperature label material based on polyimide film, combined with a printable coating designed specifically for SMT process, has excellent printing effect and high temperature resistance. This material is mainly used for marking circuit boards and other electronic components in SMT processes, with a temperature resistance of up to 350 ℃ @ 50min. After passing through the furnace, it can be torn off without leaving any residue, making it the best choice for process materials. There are two main thicknesses, 1mil (0.025mm) and 2mil (0.05mm), with two colors: smooth and matte. Customized color removable adhesive high-temperature resistant labels are available.

The removable adhesive high-temperature resistant label can be repeatedly peeled off before passing through the furnace. After passing through the furnace at high temperature, the label is peeled off from the PCB board without leaving any residue adhesive on the circuit board. It is often used for identification on SMT repeated furnace fixtures. The removable adhesive high-temperature resistant label has the following product characteristics:

1. Before passing through the tin furnace, it can be repeatedly pasted, and after passing through the furnace, remove the label without leaving any residue;

2. There are two options for the base paper: PET and Grassin. Grassin base paper is recommended for easy die-cutting and more conducive to barcode printer printing;

3. Excellent high temperature resistance, chemical solvent resistance, and extremely strong wear resistance.

The removable adhesive high-temperature resistant label is designed specifically for high-temperature lead-free soldering applications. The label is particularly suitable for heat transfer printing, saving you identification costs while ensuring high quality.

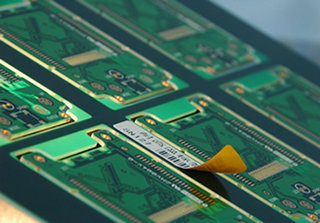

Removable high-temperature label application

1. High temperature resistant label, removable high temperature label 1. It is mainly used for barcode applications on PCB circuit boards or related electronic components, which require both high temperature resistance and process requirements such as repeated labeling and removal of labels after passing through the furnace;

2. Used for high-temperature resistant digital identification in industries such as automotive electronics, steel, casting, and aluminum, as well as quality traceability of metal component heat treatment processes;

3. Can be printed on-site with a barcode printer, capable of producing high-definition barcodes and text.

300 ℃ high temperature resistant label

The technical parameters of the 300 ℃ high-temperature resistant hanging tag are that the white polyimide film high-temperature sticker is designed to improve its performance for use at extremely high temperatures. Their characteristics make them particularly suitable for thermal conductive barcode labels used in the production process of printed circuit boards. High quality and cost-effective, widely used in industries such as electronics, automotive, and home appliances.

Capable of withstanding extreme temperatures during component soldering, these advanced labels even resist direct contact with lead-free solder, which is typically 30 to 40 ° C higher than conventional lead solder. These films will also remain white, barcode readability, and adhesive performance exposed to 300 ° C for up to one minute.

Smooth, ultra consistent, and highly transparent white coated polyimide enables high-resolution (600dpi) printing and acceptance of traditional inks, as well as heat transfer printing and high-quality resin tapes. Improved durability and high chemical resistance ensure strict cleaning during the post assembly stage of the circuit board, including the use of infrared and irritating chemicals. They also provide excellent wear resistance and strip-shaped stains.

600 ℃ high temperature resistant hanging tag

The 600 ℃ high-temperature resistant hanging tag is a PI film coated with high-temperature resistant coating, mainly developed for the growing demand of customers in the steel industry for product traceability. It is specifically used on steel and aluminum molded parts. This material can resist the influence of surrounding factors such as climate and industrial environment, such as oil pollution, emulsifiers, acid and alkali erosion, as well as the impact of wind, rain, lightning, ultraviolet rays and other harsh weather conditions during transportation and storage, ensuring excellent performance in various extreme and harsh application environments. In order to ensure smooth waste discharge, suitable die-cutting knives should be specially selected for processing.

Suitable for UV printing ink or heat transfer carbon tape printing. Please refer to the technical manual for the die-cutting requirements of the product. Due to production requirements, there are 2 joints in every 500 meter long roll. The standard storage period in an environment with a temperature of 22 ° C and a relative humidity of 50% is 12 months. It is recommended to process and use this label within 12 months after purchasing the materials.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.