Exploring the Dynamics of Sticker Label Industry**

The sticker label industry has witnessed remarkable growth in recent years, driven by a surge in demand across various sectors. This article delves into the intricate facets of this dynamic industry, shedding light on its key components, manufacturing processes, and emerging trends.

The Essence of Sticker Labels

Sticker labels serve as indispensable elements in packaging, branding, and communication. They are versatile, acting as both functional and aesthetic components. Sticker labels find applications in a myriad of industries including food and beverage, pharmaceuticals, cosmetics, and logistics, among others.

The Manufacturing Process

The production of sticker labels involves a meticulous process that ensures high quality and precision. Raw materials such as adhesive materials, facestock, and release liners are selected based on the specific requirements of the label. These materials undergo a series of treatments including coating, lamination, and printing to achieve the desired attributes.

Coating: Enhancing Adhesive Properties

Coating is a critical step in the sticker label manufacturing process. It involves applying a layer of adhesive material onto the facestock. The choice of adhesive material depends on factors such as application surface, temperature conditions, and desired permanence. Heat treatment techniques play a pivotal role in enhancing the adhesive properties, ensuring labels adhere effectively in diverse environments.

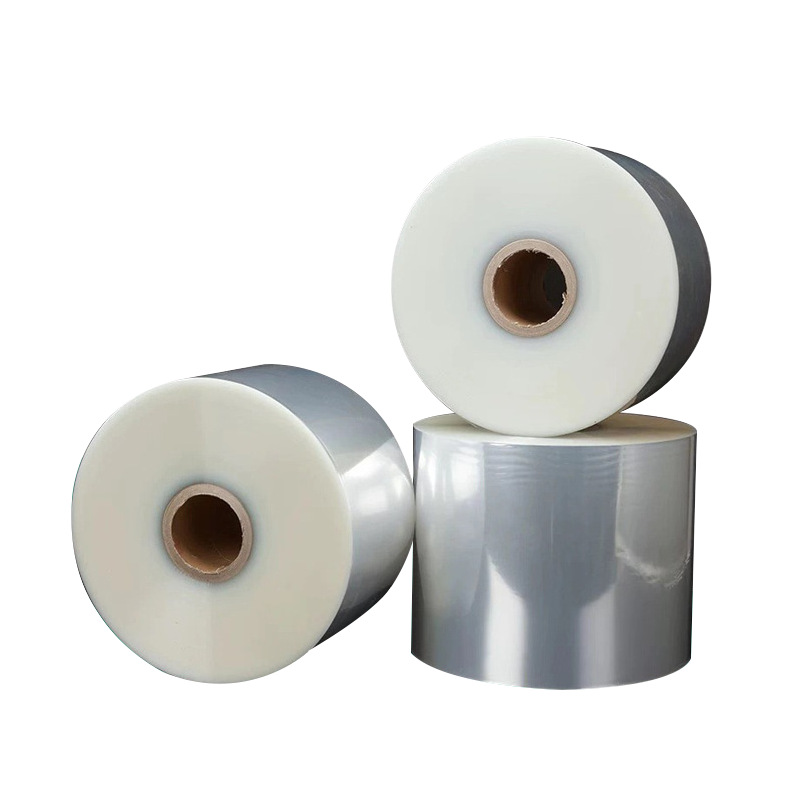

Lamination: Strengthening Durability

Lamination involves sandwiching the adhesive-coated facestock between a release liner and a protective layer. This process imparts durability and resilience to the sticker label, safeguarding it from environmental factors and mechanical stress during handling and application.

Printing: Infusing Identity and Information

Printing is a crucial stage where labels acquire their distinct visual identity. Advanced printing technologies, including flexography, digital printing, and screen printing, enable the incorporation of vibrant colors, intricate designs, and essential information such as product details, barcodes, and regulatory compliance.

Emerging Trends: Technology and Sustainability

The sticker label industry is evolving in response to technological advancements and growing environmental consciousness. Digital printing is gaining prominence, offering high-resolution, cost-effective solutions with minimal setup time. Moreover, the industry is witnessing a shift towards eco-friendly materials and sustainable practices, reflecting a commitment to reducing environmental impact.

Customization and Personalization

As consumer preferences continue to diversify, customization and personalization have become paramount in the sticker label industry. Brands are leveraging variable data printing techniques to create unique, individualized labels that resonate with target audiences. This trend not only enhances brand loyalty but also fosters a deeper connection between consumers and products.

Regulatory Compliance and Security Features

Adherence to regulatory standards and the incorporation of security features are imperative in certain industries, particularly pharmaceuticals and food packaging. Sticker labels play a pivotal role in ensuring product authenticity and consumer safety. Advanced technologies, such as holographic elements and tamper-evident materials, are employed to meet these stringent requirements.

Conclusion: Pioneering the Future of Packaging

The sticker label industry stands at the forefront of innovation and sustainability, driving advancements in packaging and brand communication. With a focus on technological integration, customization, and environmental responsibility, this industry is poised to shape the future of packaging solutions across diverse sectors.

For businesses seeking high-quality sticker label solutions, Heat Treatment Business Card stands as a reliable partner, offering expertise in adhesive technologies and a commitment to excellence.

*Disclaimer: The information provided in this article is for informational purposes only and does not constitute professional advice. Readers are advised to seek professional guidance for specific applications and requirements.*We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.