What impact does the material selection of adhesive labels have on product quality?

1. Material quality: Adhesive labels made of different materials have different qualities. Generally speaking, high-quality adhesive label materials are sturdy, flexible, and wear-resistant, which can ensure that the labels are not easily damaged during use and maintain a clear appearance of the product.

2. Adhesive and Fixation: The adhesive and fixation of self-adhesive labels directly affect whether the label can be firmly attached to the product packaging. Choose high-quality materials, and the adhesive on the back of the label has high stickiness, which can firmly adhere to the packaging surface without easy detachment, improving the packaging quality of the product.

3. Weather resistance: Adhesive labels made of different materials also have differences in weather resistance. In humid or high-temperature environments, some low-quality adhesive labels may fade, peel off, and affect the appearance and quality of product packaging. Therefore, choosing materials with good weather resistance is very important.

4. Environmental friendliness: With the increasing awareness of environmental protection, more and more companies are choosing environmentally friendly adhesive label materials, such as using biodegradable materials or printing environmentally friendly inks. Choosing environmentally friendly materials can reduce pollution to the environment, enhance a company's sense of social responsibility, and also better meet consumers' requirements for environmental protection.

Overall, the material selection of adhesive labels has a significant impact on product quality. When choosing adhesive labels, enterprises should comprehensively consider factors such as product packaging needs, usage environment, and environmental requirements, and choose high-quality materials that are suitable for their own products to improve the packaging quality and brand image of the products.

What carbon tape is suitable for matte silver adhesive labels?

The carbon tape suitable for matte silver adhesive labels is mainly resin carbon tape

Characteristics of Resin Carbon Ribbon

Durability: Resin carbon tape has high durability and wear resistance, and can maintain the clarity and durability of handwriting in different environments. When used in conjunction with matte silver adhesive labels, the printed content can remain clear for a long time and is not easily faded or blurred

Waterproof and oil resistant: Resin carbon tape usually has good waterproof and oil resistant properties, which can effectively prevent the influence of water or oil on the printing effect. This is particularly important for the application of matte silver adhesive labels in damp or greasy environments

Print quality: Resin carbon tape usually produces good printing results, allowing for clear and durable patterns and text on matte silver adhesive labels. This ensures the printing quality and readability of the matte silver adhesive label

In summary, resin carbon tape should be selected for printing matte silver adhesive labels to ensure clear, durable, and reliable printing results. When selecting carbon ribbon, it is also necessary to determine the appropriate model and specifications based on actual needs and the requirements of the barcode printer

Which material should be chosen for electronic product adhesive labels?

For electronic product labels, our main consideration is the flame retardancy of the material

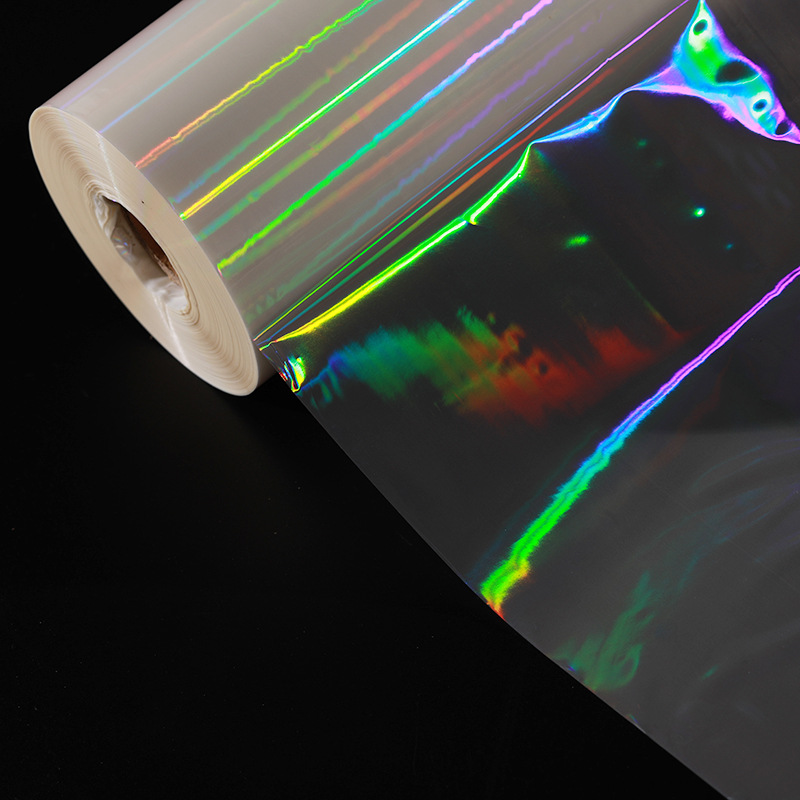

PET self-adhesive label:Polyester film, which can be processed or untreated on the surface.. There are several types of surfaces, including pure white, sub white, transparent, and various types of bright silver, sub silver, etc. that have undergone coating solutions. Due to its high tensile strength and properties such as moisture resistance, high temperature resistance, alkali resistance, and solvent resistance, it can be used as a labeling material for various electronic and mechanical devices that can be affixed to a horizontal surface

When choosing the material for adhesive labels, we also need to consider adhesion and applicability. Adhesive strength is a key factor in whether a label can be firmly attached to a product, while applicability refers to whether the label is suitable for printing and processing

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.