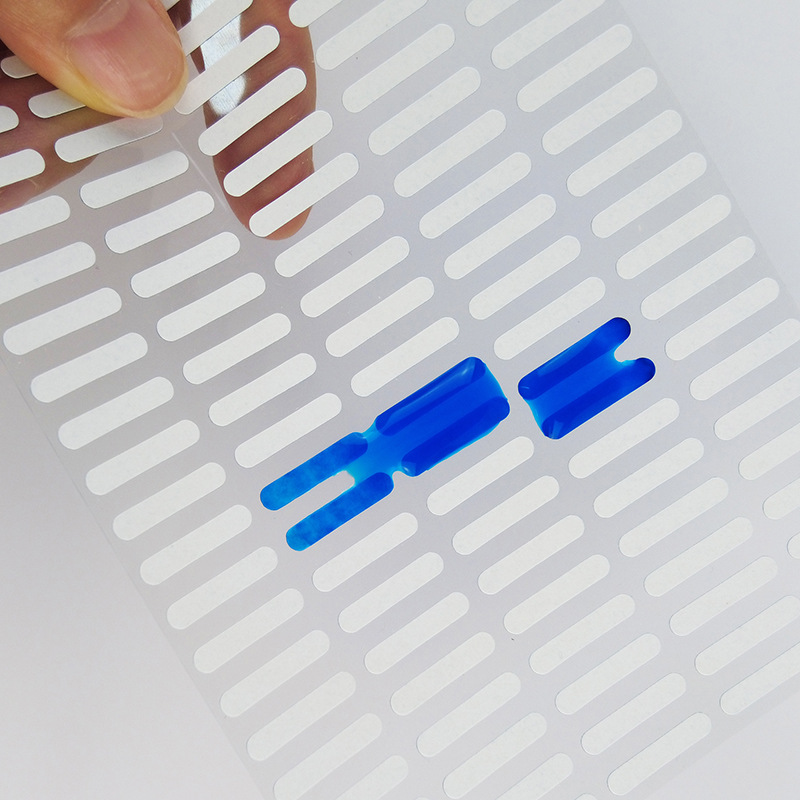

PET self-adhesive label

PET is a fibrous material with good rigid ductility, capable of withstanding certain high temperatures, enduring harsh environments, and resisting corrosion from strong acids, strong bases, and other chemicals. Commonly used fabrics include matte silver, matte white, shiny silver, pure white, and fully transparent.

The temperature resistance range of basic PET labels is -20℃ to +120℃, with a minimum label application temperature of 10℃;

For PET labels with strong adhesion used on cables, the temperature resistance range is -20℃ to +100℃, with a minimum label application temperature of 10℃.

PET label paper

PET label paper comes in various colors such as bright white, matte white, silver, etc. Common colors include silver dragon and silver silver label paper, which have excellent high temperature resistance, chemical corrosion resistance, good waterproof performance, durability, tensile strength, acid and alkali resistance, scratch resistance, friction resistance and other characteristics. However, the cost is relatively higher when used in conjunction with resin based carbon tape printing. Widely used in electrical, electric, and mechanical equipment.

Laser black PET label

Laser black PET label is a 2mil PET label material with a black glossy coating and white sub layer, specifically designed for laser labels in CO2, YAG, UV, or fiber diode marking systems

Laser black PET label product parameters

Coating: Black

Thickness: 2mil

Substrate: PET

Temperature resistance range: -40-180 ℃

Certification standard: RoHS/SGS

Product characteristics of laser black PET label

Smooth and consistent surface, good dimensional stability, excellent printing effect, laser scanning capability, chemical corrosion resistance, solvent resistance, outstanding friction resistance, high temperature resistance, and high humidity performance can be used for under hood identification in automobiles

Application of Laser Black PET Label Products

ID and warranty labels, asset traceability, durable product nameplates, safety barcode labels

Can PET labels be used for chemical labeling?

Chemical labels can use PET labels. PET labels are made of polyester film, which is a polymer material with good hardness and brittleness. It can withstand certain high temperatures, resist harsh environments, and resist corrosion from chemicals such as acid and alkali. It is very suitable for outdoor and high-quality labels.

These characteristics of PET labels make them very suitable for use as chemical labels, as they can clearly and persistently display important information about chemical products, such as name, hazard level, risk statement, etc., ensuring the safe use of the product.

In addition, the common colors for PET labels include matte silver, matte sub white, bright silver, bright white, and transparent. You can choose the appropriate color according to your actual needs. There are also various thickness specifications to choose from, such as 25 series (1 series=1um), 50 series, 75 series, etc., to meet the requirements of different manufacturers and products.

What labels are usually used for plastic buckets

Plastic drums are a commonly used packaging container. Unlike packaging containers made of other materials, plastic drums have the characteristics of light weight and relatively low price, so their use is becoming increasingly widespread. As an important part of packaging, choosing the appropriate label material and adhesive strength is crucial for maintaining the beauty and quality of the packaging.

For plastic bucket labels, PET labels can generally be chosen, which have high water resistance, pollution resistance, and excellent adhesive strength. PET label material has certain advantages such as temperature resistance, friction resistance, high strength, and good transparency, and it is more suitable for pasting on the surface of plastic drums compared to other materials of labels.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.