In the bustling world of commerce, the pressure on businesses to stand out has never been more intense. As shelves become increasingly crowded and online stores overflow with options, a brand's ability to create an immediate and lasting impression is paramount. One simple yet powerful way to achieve this is through distinctive, high-quality sticker materials. These aren't just ordinary stickers; they are carefully crafted pieces of art, engineered to transform packaging and capture consumer attention. Whether you're looking to amplify your product’s presence or add a dash of luxury, the material you choose for sticker printing can be a game-changer.

But what materials are actually used in sticker printing, and how do they affect the final product? The world of sticker materials extends far beyond mere paper. Today's sticker printing leverages everything from high-tech vinyl and eco-friendly biodegradable films to specialty laminates and industrial-grade adhesives. The options are vast, each bringing its own set of advantages and aesthetic possibilities. It’s time to pull back the curtain on the rich variety of materials available and explore their distinctive features.

A Comprehensive Look at Sticker Materials

Let’s begin by diving deep into the most commonly used materials in sticker printing. Each material brings a different tactile and visual experience, not to mention various functional properties that can influence durability, application, and overall design potential.

1. Digital Printed Self Adhesive Vinyl Material

One of the most popular materials in the realm of sticker printing, Self Adhesive Vinyl, offers unparalleled versatility. Its flexibility and resilience make it ideal for both indoor and outdoor applications. What sets Digital Printed Self Adhesive Vinyl Material apart is the ability to print in vibrant, high-definition colors, bringing designs to life with unmatched clarity. The adhesive backing is strong yet removable, providing ease of use on a wide range of surfaces—from product packaging to signage.

2. Biodegradable Film Material

As the world moves towards more eco-conscious choices, Biodegradable Film Material offers a green alternative without compromising quality. This material is derived from sustainable sources and decomposes naturally over time, making it an excellent option for environmentally-minded brands. Despite its eco-friendliness, biodegradable film does not lag in durability. It resists tears and holds up well in various weather conditions, offering a guilt-free yet robust sticker solution.

3. Durable Sticker Material

As the name suggests, Durable Sticker Material is designed to withstand the toughest conditions. This could include exposure to UV rays, moisture, and abrasion. Often employed in industrial or outdoor settings, this material’s resilience ensures your stickers last as long as you need them to—whether that's for months or even years. These stickers can brave elements like water, oil, and extreme temperatures, all while retaining their vibrant colors and adhesive properties.

4. Special Paper Material

For brands seeking a more tactile, artisanal feel, Special Paper Material offers a textured alternative. The surface may mimic the appearance of fine art paper, adding an extra layer of sophistication to the finished product. These stickers are particularly popular for limited-edition packaging, hand-crafted goods, and organic or natural products. The matte or slightly grainy finish of special paper lends a distinctive and luxurious feel, contrasting with the sleekness of more modern materials.

5. Car Wrap Vinyl Film Material

A heavier-duty cousin of the standard vinyl sticker, Car Wrap Vinyl Film Material is engineered for high-impact visuals. As the name suggests, this material is often used in vehicle wraps but can just as easily be employed in oversized sticker designs for products, displays, or advertising purposes. Car wrap vinyl is thick, malleable, and built to stretch over contours while maintaining adhesion. Its durability makes it resistant to scratches, chips, and fading, even in harsh outdoor environments.

6. Rewritable Whiteboard Sticker Material

Function meets flexibility with Rewritable Whiteboard Sticker Material. Ideal for both promotional use and practical applications, these stickers allow users to write, erase, and rewrite information as needed. Whether for labeling purposes, promotions that require frequent updates, or even customizable to-do lists, these stickers merge utility with design. The surface is smooth, matte, and ready for any dry-erase marker, offering a practical solution that blends seamlessly into any environment.

7. Color Cutting Vinyl Materials

For those looking to inject vibrancy into their stickers, Color Cutting Vinyl Materials are a must. Available in a spectrum of brilliant hues, these vinyl materials allow intricate designs to be cut directly into the material, resulting in sharp, eye-catching visuals. The solid, uniform color from edge to edge ensures the sticker pops on any surface, whether it’s affixed to a product, display, or vehicle.

8. DTF Transfer Film

Direct-to-Fabric (DTF) Transfer Film represents a leap forward in fabric printing technology. With DTF, designs are transferred directly onto textiles with vivid detail, opening up new avenues for creative applications. The flexibility of this material is ideal for fashion brands, custom apparel makers, or anyone wanting to print stickers that can be applied to fabric surfaces. The transfers are durable and withstand multiple washes without fading, ensuring long-term quality.

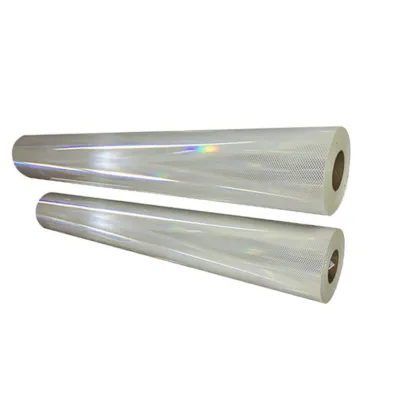

9. Laminated Film

For those who want their stickers to look sharp over time, Laminated Film provides a protective shield. Applied as a final layer over the printed sticker, this film guards against scratches, UV exposure, and moisture. Laminated Film is available in both glossy and matte finishes, offering businesses the opportunity to add a touch of sophistication to their designs while enhancing durability.

10. Industrial Tape Material

On the more functional end of the spectrum, Industrial Tape Material is designed for serious work. This sticker material focuses on strong adhesion and durability in harsh conditions, often found in industrial settings. Its applications include safety labels, heavy-duty packaging, and警示 signs. Though it may not be as glamorous as vinyl or laminated options, the strength of industrial tape material is unmatched when it comes to longevity and performance under pressure.

The Aesthetic and Functional Impact of Different Materials

While the choice of sticker material undoubtedly impacts the visual appeal, its influence extends to the tactile and functional aspects as well. High-quality materials enhance brand perception, increase product visibility, and add intrinsic value to your offerings. But what exactly can businesses expect when choosing different materials? Let's break down the potential benefits:

Creating Lasting First Impressions

From the consumer’s very first touch, the sticker material can set the tone for their entire interaction with your product. Vinyl or laminated materials provide a polished, sleek surface, communicating luxury and attention to detail. Biodegradable or special paper materials send a message of environmental responsibility and artisanal care. In either case, the right material choice ensures that your product leaves a lasting, positive impression.

Durability Across Environments

Some stickers need to stand up to extreme weather, frequent handling, or even chemicals. Materials like Durable Sticker Material and Car Wrap Vinyl Film are specifically designed to withstand these challenging environments. Whether your stickers are destined for outdoor billboards or factory floors, selecting a robust material ensures your message remains intact and legible for as long as possible.

Sustainability and Consumer Values

In a world increasingly focused on environmental impact, Biodegradable Film Material and eco-friendly options speak directly to consumers who prioritize sustainability. Offering stickers that decompose naturally, without leaving harmful residues, aligns your brand with eco-conscious values, potentially broadening your appeal to a more environmentally-minded audience.

Versatility in Design and Use

Certain materials provide greater design flexibility. DTF Transfer Film and Color Cutting Vinyl Materials allow for vivid, detailed graphics with a wider range of textures and visual effects. These stickers can be used across a range of products, from fabric to complex packaging shapes, giving designers greater freedom to innovate. Additionally, Rewritable Whiteboard Sticker Material opens doors for interactive applications where information can be changed regularly, adding utility to the visual aspect.

How Sticker Materials Can Elevate Your Business Packaging

It’s clear that the right material choice can have far-reaching effects on the overall consumer experience. Let’s examine more closely how integrating premium materials into your sticker printing strategy can take your brand to the next level:

Enhanced Brand Perception

Selecting a luxurious material such as Foil Labels or Laminated Film can give your products a high-end, polished appearance. This, in turn, elevates your brand's overall perception, potentially allowing you to command higher prices and attract a more discerning customer base.

Memorable Unboxing Experiences

Premium sticker materials can make the unboxing experience truly special. When customers open their packages to find shimmering foil or high-gloss labels, their initial impression of your brand is immediately heightened. This memorable experience can lead to increased brand loyalty and word-of-mouth referrals.

Standing Out in a Crowded Marketplace

In retail environments where competition is fierce, a unique sticker material like holographic or glitter options can make your products leap off the shelves. The more eye-catching and luxurious your packaging, the more likely it is to grab attention amid a sea of competitors.

Designing with the Right Material and Finish

Selecting the right material for your stickers involves not just practical considerations but also aesthetic ones. When embarking on the design process, keep the following tips in mind:

-

Reflect Your Brand Identity: Stickers should be a natural extension of your brand. Whether your brand is modern, eco-friendly, or artisanal, ensure your material and finish choices align with your brand identity.

-

Strike a Balance Between Visual and Tactile Elements: Sometimes, the tactile experience of a material can be as impactful as its visual appearance. Consider how the texture of materials like Special Paper or Biodegradable Film can contribute to a well-rounded sensory experience.

-

Keep It Simple and Elegant: Luxury often stems from simplicity. You don’t need overly intricate designs when high-quality materials and clean, effective imagery speak for themselves. Let your chosen material shine through with refined design choices.

-

Ensure High-Quality Imagery and Text: No matter how premium your sticker material is, low-quality images or hard-to-read fonts will detract from its overall impact. Always use crisp graphics and legible text to maintain a polished look.

Choosing the right material for sticker printing is an art and a science. It’s about understanding the balance between aesthetics, durability, and functionality while keeping your brand identity at the forefront. From vinyl and laminated films to biodegradable options and specialty papers, your material choices set the tone for how the world perceives your brand.

Remember, stickers are more than just labels—they are a powerful branding tool. When crafted with the right materials and thoughtful design, they can elevate your product packaging, create unforgettable unboxing experiences, and ultimately boost your brand’s perceived value. Invest the time to choose materials that align with your goals, and watch as your brand ascends above the noise of a crowded marketplace.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.