The Dilemma: Waterproof Labels or Weatherproof Labels?

When navigating the realm of sticker production for your enterprise, the choice between waterproof and weatherproof labels looms large. Though they share similarities, their intended functions diverge significantly. A waterproof sticker courageously faces moisture, while a weatherproof label, a stalwart guardian of products, braves not just moisture but also UV light and extreme temperatures. Remember, weatherproof does not automatically imply waterproof. Each type possesses unique properties tailored to specific environmental challenges.

Deciphering the Right Label for Your Business

Selecting the perfect label for your product need not be an odyssey. To aid in this quest, let us dissect the essential properties of these labels, arming you with the knowledge to make an informed decision for your burgeoning business.

A Glimpse into Various Label Types

Before delving deeper, grasp the fundamental differences among water-resistant, waterproof, and weatherproof labels. Each has its forte, and understanding these distinctions is paramount.

Water-Resistant Labels

Water-resistant labels are akin to a temporary raincoat—adequate for a brief encounter with moisture. They often feature a waterproof coating atop standard adhesive label stock. However, prolonged exposure to moisture will see water creeping along the edges, potentially marring shipping labels and barcodes.

Waterproof Label Options

True to their name, waterproof labels scoff at water, whether submerged or simply damp. Every layer, from adhesive to the top coat, rebuffs moisture. Such labels are indispensable for products housed in wet environments, like water bottles, ensuring durability and clarity.

Weatherproof Labels

Weatherproof labels, versatile sentinels, defend against a multitude of environmental assailants. These labels, boasting UV-resistant ink and high-adhesion properties, refuse to be easily parted from their surfaces, offering peace of mind for products exposed to the elements.

UV-Resistant Weatherproof Labels

Sunlight, the perennial foe of label longevity, can fade a full-color label into oblivion if not properly countered. UV-resistant weatherproof labels, forged with specialized inks tested under simulated sunlight, resist such fading. This is critical for outdoor products or those near windows. The Blue Wool scale, borrowed from textiles, quantifies this resistance, with higher ratings indicating superior resilience. ASTM standards, such as D3424, further testify to these labels' endurance, aiding in selecting inks that stand up to light's ravages.

Temperature Resistant Weatherproof Labels

Temperature extremes, both hot and cold, test adhesive fidelity. Freezer-grade adhesives laugh in the face of frost, while cold-temperature adhesives bravely withstand subzero conditions. High-temperature scenarios often involve hot-fill processes, and adhesives must endure these thermal trials to keep labels intact. The Shear Adhesion Failure Temperature (SAFT) test serves as the ultimate arbiter, determining an adhesive's high-temperature mettle.

Service Life of a Label

Every label has a lifespan, a journey from pristine application to eventual wear. For materials under HazCom regulations, this lifespan must cover the product's entire existence, requiring labels that endure years of outdoor storage. It's essential to distinguish between service life and shelf life; high-quality vinyl and polyester labels, with superior top coatings, generally offer extended utility. For less demanding conditions, paper labels may suffice if maximum water protection isn't needed.

Crafting stickers: Standard Paper vs Vinyl Sticker Paper

Transitioning from label types to materials, consider the choice between standard sticker paper and vinyl sticker paper. This decision often pivots on the specific demands of your product and environment.

Standard Sticker Paper

Standard sticker paper, economical and versatile, fits many everyday applications. However, its resilience falters under harsh conditions, particularly in moisture-rich environments.

Vinyl Sticker Paper

Vinyl sticker paper, robust and flexible, excels in durability. It defies not only water but also abrasions and tears, making it ideal for products subjected to rigorous handling or outdoor exposure.

A Deep Dive into Specialty Materials

Moving beyond the conventional, a myriad of specialty materials await those seeking unique sticker properties. From biodegradable films to rewritable whiteboard stickers, each material presents distinct advantages for specialized applications.

Biodegradable Film Material

Eco-conscious businesses may opt for biodegradable film material, a testament to sustainability without compromising on durability.

Durable Sticker Material

For those demanding endurance beyond the ordinary, durable sticker materials rise to the occasion, standing up to the toughest environmental challenges.

Special Paper Material

Special paper materials, offering unique textures and finishes, cater to discerning tastes, blending aesthetics with functionality.

Car Wrap Vinyl Film Material

Car wraps, vivid and attention-grabbing, utilize specialized vinyl film materials designed to stretch and conform to vehicle contours while enduring the rigors of road travel.

Rewritable Whiteboard Sticker Material

Ideal for educational and office settings, rewritable whiteboard sticker materials foster creativity and flexibility, inviting repeated use and revision.

Exploring Additional Materials and Applications

Expanding further, the universe of sticker and label materials includes options like color cutting vinyl materials, DTF Transfer Film, and laminated film, each opening new avenues for creative and functional applications.

Color Cutting Vinyl Materials

For intricate designs and vibrant presentations, color cutting vinyl materials are unparalleled, providing precision and pop.

DTF Transfer Film

DTF transfer film offers a versatile solution for fabric applications, ensuring designs are both vivid and durable.

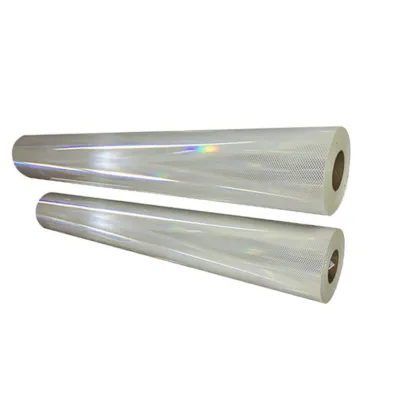

Laminated Film

Laminated film, often used as a protective top layer, enhances durability while adding a touch of professionalism and polish.

Industrial Tape and Beyond

In industrial applications, the demand for robust adhesives grows, with industrial tape serving as a critical component in various manufacturing and construction contexts.

Making Informed Choices for Your Sticker Needs

Ultimately, the choice between standard and specialty materials, waterproof and weatherproof labels, hinges on understanding each product's unique requirements and environmental challenges. Equipped with this knowledge, your business can confidently select the right materials, ensuring both quality and longevity in every sticker and label produced.

Final Thoughts

In the world of labels and stickers, diversity reigns supreme, offering boundless possibilities to match every need and niche. Through careful consideration of materials and environmental demands, your high-tech enterprise can create stickers that not only stick but endure, embodying both form and function. As you navigate this sticky subject, may your choices reflect the ingenuity and dedication inherent in your business's mission.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.