The world of industrial labeling and identification is evolving rapidly, with an ever-growing demand for versatile, durable, and eco-friendly solutions. Amidst this transformative landscape, Self Adhesive Vinyl Material emerges as a standout option, celebrated not just for its sticky efficacy but also for its adaptability in design, durability, and sustainability. From Digital Printed Self Adhesive Vinyl to Biodegradable Film Material, this material offers endless possibilities for a wide array of industries. But what truly sets it apart? Let’s dive deep into the nuances of Self Adhesive Vinyl Material and explore how it provides both convenience and customization in design like no other.

The Cellulose Foundation: Beyond Ordinary Paper

At the foundation of many advanced adhesive solutions lies cellulose film—a natural, flexible, and transparent material derived from cotton pulp or wood pulp. Unlike traditional paper, cellulose film undergoes a special regeneration process, transforming it into what we commonly call "cellophane". This process not only grants the material its transparency but also ensures that it remains flexible, combining the best qualities of both plastic and paper. In addition to these features, the environmental benefits of cellulose film—coupled with its potential for customization—are propelling it to the forefront of modern adhesive technologies.

But cellulose film isn’t just about appearance. The adhesive it partners with is equally groundbreaking. Environmental-friendly pressure-sensitive glue, made using biodegradable, water-based compounds like butyl acrylate, water, rosin resin, and additives, ensures that the entire product remains eco-conscious. This glue is biodegradable, breaking down into harmless substances such as water and carbon dioxide, thus allowing it to be recycled alongside waste cartons. The versatility doesn’t stop there—custom colors such as white, red, blue, coffee, and beige are available, making the material ideal for logos and bespoke designs.

The Shift Towards Eco-Conscious Labeling

An interesting revelation is that 80 billion pieces of clothing are manufactured every year, and a staggering 90 percent use plastic for labels and price tags. With consumers increasingly leaning toward environmentally responsible brands, this mass usage of plastic is being scrutinized like never before. The solution? Biodegradable cellulose paper films and eco-friendly adhesives that offer similar, if not better, durability and aesthetic appeal, without harming the environment.

The post-pandemic era has seen heightened consumer awareness regarding health, comfort, and sustainability. More people are questioning the environmental footprint of their clothing and accessories, demanding transparency from brands about materials and manufacturing practices. Here, Self Adhesive Vinyl Materials from OwnLikes not only meet the stringent requirements of eco-conscious clients but surpass expectations by offering custom solutions such as bio-based materials, degradable films, and moisture barrier coatings, all of which are critical for today’s evolving market.

OwnLikes: The Epitome of Innovation and Sustainability

OwnLikes offers an integrated solution that bridges the gap between traditional industrial adhesives and future-forward eco-labeling. From advanced cellulose paper films to high-performance pressure-sensitive adhesives, OwnLikes provides fibers and films that boast tensile strength comparable to nylon and polyester. What differentiates them is their relentless focus on sustainability without compromising on performance or customization.

Take, for example, their flagship product OL008. This cellulose paper film isn’t just another product on the shelf—it’s a testament to innovation, combining:

• Sustainable raw materials from responsibly managed forest resources.

• A fully biodegradable and sustainable product lifecycle.

• Enhanced high transparency and tensile strength through innovative coating processes.

• FSC Certification and SGS Biodegradation Certification, ensuring eco-friendly practices from start to finish.

Each attribute is designed with a circular economy in mind, where recycling and renewable resources take precedence, thus ensuring a reduced environmental footprint.

Custom Solutions for an Ever-Changing Market

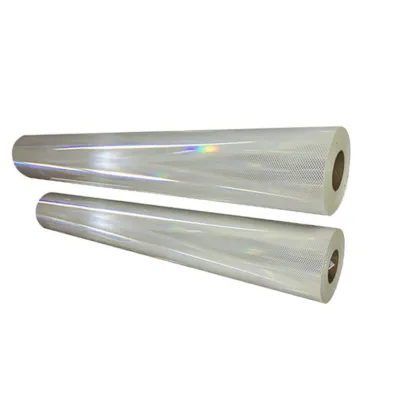

Customization is at the heart of OwnLikes’ offerings. The company can tailor products based on size specifications, logo prints, and even the thickness of release paper. They offer versatile glue coating options, including water glue, hot melt glue, oil glue, and removable glue, ensuring there is a solution for every industrial need.

Furthermore, OwnLikes provides three distinct adhesive schemes, giving clients the freedom to select:

- Biodegradable cellulose paper film (25-40u) + water glue + substrate (grid or transparent bottom).

- Biodegradable cellulose paper film (25-40u) + oil adhesive (grid or transparent bottom).

- Biodegradable cellulose paper film (25-40u) + movable adhesive (grid or transparent bottom).

This flexibility allows businesses to choose what works best for their unique applications while adhering to their own sustainability goals. Whether it's for automatic labeling, roll material, or custom cutting, OwnLikes ensures that every solution can be tailor-made.

Debunking Myths: Cellulose Film vs. Plastic Membrane

A frequent question many clients ask is, “How can we be sure this material isn’t just another plastic membrane?” While cellulose film may visually resemble plastic, it’s worlds apart in terms of composition and environmental impact. Here are three quick ways to verify the authenticity of cellulose film:

- Ignition Test: When safely ignited, cellulose film burns rapidly without dripping, leaving behind paper ash.

- Smell Test: Upon burning, the material emits the same smell as burning paper, not plastic.

- Tear Test: Cellulose film is easy to tear longitudinally, unlike plastic which is more resistant.

OwnLikes cellulose film stands out as transparent paper—environmentally friendly, recyclable, and fundamentally different from plastic in its life cycle and impact.

Supporting Documents and Certifications: The Proof Is in the Paperwork

OwnLikes doesn’t just make empty promises. Their products come backed by a range of certifications, assuring clients that they are adhering to global standards of sustainability and quality. Some of the prominent certifications include:

- EU Industrial Composting Certificate

- EU Home Composting Certificate

- FSC Forest Certificate

- RoHS Report

- FDA Food Grade Certification

- Halogen Reports

These certifications underline their commitment to both environmental responsibility and safety. Whether it's a question of food safety or biodegradability, OwnLikes ensures that each product passes rigorous testing.

Performance That Speaks for Itself

One may wonder how these eco-friendly products hold up in real-world conditions. Through extensive testing, OwnLikes’ cellulose paper films have proven themselves in high-temperature (60%) and high-humidity (85%) environments over 48 hours. These films have successfully endured processes like coating, shallow bumping, UV printing, and high-frequency heat sealing, showing they can thrive under even the toughest conditions.

Biodegradability: Not Just a Buzzword

It’s crucial to note that biodegradation only occurs under specific conditions over an extended period (more than 90 days). This requires the right balance of microorganisms, temperature, and humidity—conditions not typically encountered during regular use or transportation. Thus, consumers can confidently use these materials without worrying about premature degradation.

The Advantages Over OPP/PET Films

When compared to traditional OPP and PET films, OwnLikes’ cellulose-based materials showcase multiple advantages:

- Biodegradability: Naturally degrades without leaving harmful residues.

- Antistatic Properties: Reduces dust and particle attraction.

- High Transparency and Color Reproduction: Delivers impeccable print quality.

- Strong Rupture Resistance: Handles rigorous use and environmental stress.

- Odorless and Non-toxic: Safe for both consumers and the environment.

- Easily Tearable: For custom applications requiring manual adjustments.

By transitioning to cellulose-based films, businesses are not only meeting environmental goals but also gaining access to high-performance materials that outperform conventional options.

Conclusion: Convenience Meets Innovation

As industries shift towards more sustainable practices, the demand for Self Adhesive Vinyl Materials that can adapt to these changing landscapes grows. Whether it’s through the use of biodegradable cellulose films or eco-friendly adhesives, OwnLikes continues to offer products that represent the ultimate convenience in design—versatile, customizable, durable, and sustainable. These solutions not only help companies reduce their environmental footprint but also offer unparalleled performance for labels, packaging, and a wide range of industrial applications.

The story of Self Adhesive Vinyl Material is one of continual innovation and eco-responsibility. By choosing materials like biodegradable cellulose paper films, businesses make a stand for sustainability without sacrificing quality, functionality, or aesthetics. In this brave new world of industrial design, the convenience of Self Adhesive Vinyl Material isn't just a bonus—it's an essential.

With a robust combination of advanced technology, eco-certifications, and endless customization options, OwnLikes proves that when convenience and innovation meet, the result is nothing short of transformative.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.