Introduction to Self-Adhesive Vinyl in Packaging

When one thinks of packaging, the immediate images that spring to mind are cardboard boxes, plastic wraps, and adhesive tapes. However, within this seemingly straightforward realm lies a universe of innovative materials, each serving a unique purpose. Self-adhesive vinyl material, in particular, has emerged as a versatile player in the packaging industry. Unlike traditional packaging components, this material offers durability, flexibility, and sustainability. Our high-tech enterprise, specializing in industrial labeling and identification adhesives, brings forth this unique product, designed to address both functional and environmental needs.

A Leap Towards Sustainability: The Eco-Friendly Angle

Each year, approximately 80 billion pieces of clothing are manufactured, with an astonishing 90 percent relying on plastic for affixing price tags and product information labels. The fashion industry's pivot towards sustainable practices has driven innovation in eco-friendly packaging materials. Enter self-adhesive vinyl materials, which are not only biodegradable but also leverage renewable resources. Our flagship product, the biodegradable cellulose paper film, sets a new benchmark in this arena.

Understanding the Composition and Lifecycle

Our cellulose film, dubbed "cellophane," begins its journey from wood pulp fiber. This raw material, derived from sustainably managed forests, is transformed through a series of advanced processes into a flexible, transparent medium. This innovative material isn't just another packaging accessory; it embodies a biodegradable and sustainable lifecycle. With certifications like FSC and SGS Biodegradation, it aligns with the ethos of a circular economy and environmental deplasticizing.

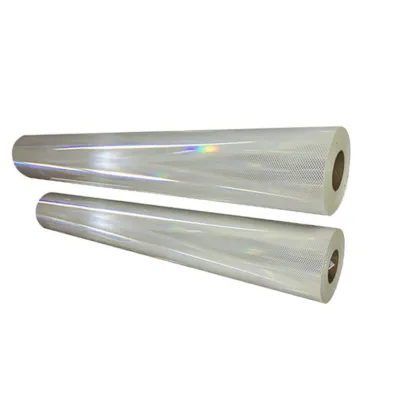

Customization: Meeting Diverse Industry Needs

In today’s consumer-driven market, customization is key. OwnLikes provides an extensive range of customizable options for self-adhesive vinyl materials. From selecting surface material weight to dyeing, laser shading, and inkjet coating, the possibilities are endless. Our offerings extend to glue coating selections, including water-based, hot melt, oil-based, and removable adhesives, tailored to meet specific customer needs. Furthermore, customers can print logos and choose from various thicknesses and specifications, ensuring the material fits seamlessly into their packaging strategies.

Tailored Solutions for Adhesive Needs

Recognizing that one size does not fit all, we present three bespoke solutions for adhesive requirements:

- Biodegradable cellulose paper film (25-40u thickness) + water-based glue + substrate (grid or transparent bottom)

- Biodegradable cellulose paper film (25-40u thickness) + oil adhesive (grid or transparent bottom)

- Biodegradable cellulose paper film (25-40u thickness) + movable adhesive (grid or transparent bottom)

These configurations cater to different application scenarios, ensuring optimal performance and adherence.

Customization Capabilities and Options

Our commitment to meeting customer demands extends beyond adhesive solutions. Size specifications can be selected, and logos or patterns can be printed with precision. We also offer automated labeling roll material and cutting services, further showcasing our adaptability and customer-centric approach.

Addressing Practical Concerns and Misconceptions

With innovation comes questions. To address common inquiries:

- Quick Verification Methods: Through ignition (fast combustion, no dripping), smell (paper-like), and tear tests (longitudinal ease), one can verify that our material is not a conventional plastic membrane.

- Supporting Documents: Certifications such as EU Industrial Composting, FSC Forest, RoHS, and FDA food grade, among others, validate our product's credentials.

- Moisture Resistance: Despite being a paper-based product, our material is moisture-proof, ensuring protection against environmental factors.

- Durability and Degradation: The product requires specific conditions for degradation, ensuring it remains robust throughout its lifecycle.

- Special Advantages Over OPP/PET Films: From biodegradability and antistatic properties to high transparency and rupture resistance, our material stands out in numerous ways.

- Post-Degradation Residue: After degradation, our material converts into harmless substances like protein and glucose, contributing to a cleaner environment.

- Recycling Feasibility: Our materials can be recycled alongside paper, making them an excellent choice for eco-conscious brands.

The Evolution of Consumer Demand and Our Response

The post-pandemic era has reshaped consumer priorities. Health, safety, and sustainability have become paramount. As human vulnerability became more pronounced, so did the expectation for brands to uphold environmental and social responsibilities. OwnLikes is at the forefront of this shift, offering integrated solutions like bio-based materials, degradable films, and moisture barrier coatings, all while maintaining performance metrics akin to traditional materials like nylon and polyester.

Embracing the Circular Economy and Reduction Goals

Our cellulose paper film product, OL008, exemplifies the integration of advanced domestic and international technologies to support sustainable development. Recycled and renewable resources form the crux of this material, aimed at reducing reliance on oil-based products. Through innovative processes, we achieve product thinning and weight reduction, significantly cutting down on raw material usage and promoting a monomer structure over composite ones.

Unmatched Versatility and Innovation

The inherent qualities of our self-adhesive vinyl materials provide unmatched versatility. From high barrier properties and odorless characteristics to ease of tear and high width consistency, they cater to a wide array of packaging needs. Furthermore, they are fully compliant with environmental protection mandates, making them an attractive proposition for brands aiming to circumvent plastic tariffs and contribute to a greener planet.

A Vision for the Future

Imagine a world where the oceans are devoid of non-degradable plastics, and marine life thrives without the threat of mutilation or ingestion. Our biodegradable materials are a step towards this vision, ensuring that in more than 90 days, what remains are harmless natural substances rather than persistent pollutants.

Navigating Challenges and Seizing Opportunities

While the path towards sustainability is fraught with challenges, OwnLikes embraces the opportunity to lead by example. Through continuous research and development, we strive to offer products that not only meet market demands but also exceed environmental expectations. Our rigorous testing protocols ensure that each product is suited for various post-processes, from high-frequency heat sealing to drop tests, maintaining integrity across diverse applications.

Conclusion

The transformative potential of self-adhesive vinyl materials in packaging cannot be overstated. From serving as an eco-friendly alternative to traditional plastics to offering high performance and versatility, these materials herald a new era in sustainable packaging solutions. As we continue to refine our products and expand our offerings, OwnLikes remains dedicated to supporting the global shift towards sustainability, one adhesive solution at a time.

This comprehensive exploration of self-adhesive vinyl materials showcases their pivotal role in modern packaging, highlighting the intersection of innovation, sustainability, and customer satisfaction. As industries worldwide embrace greener practices, our products stand ready to meet and exceed these evolving demands, embodying the essence of environmental stewardship and technological advancement.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.