Product Overview

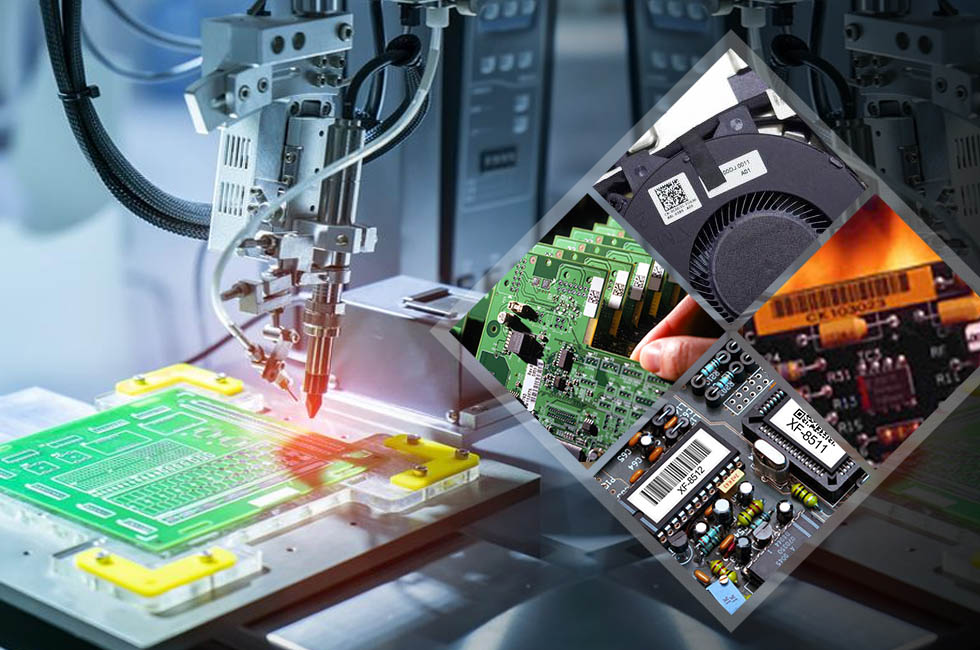

Electronic product manufacturing label stickers are specialized identification solutions designed for the electronics industry, used for product information labeling, safety warnings, traceability management, and brand display. These labels must meet requirements such as high-precision printing, durability, and compliance, and are widely used in scenarios such as PCB boards, cables, enclosures, and packaging.

Core Application Scenarios

- Product Identification

Model/Specification Label: Indicates key parameters such as product model, voltage, and power.

Serial number sticker: The sole identification mark, used for production traceability and after-sales service.

Compliance certification stickers: such as CE, FCC, RoHS, etc., which are mandatory certification marks.

- Safety Warning

High Pressure/Temperature Warning Label: Indicates operational risks and complies with safety regulations.

Anti-tampering sticker: Ensures product integrity and prevents unauthorized disassembly.

- Production process management

Barcode/QR code stickers: Used for warehouse logistics and production batch tracking.

Anti-static stickers: Used for sensitive electronic components to prevent interference from static electricity.

- Brand and User Experience

Decorative stickers: Enhance the appearance texture of the product (such as metal polishing effect, transparent UV effect).

Multilingual stickers: Meeting the language demands of the global market.

Materials and Process Characteristics

- Base Material Selection

High-temperature resistant materials: Polyimide (PI) and polyester (PET) films, suitable for reflow soldering and high-temperature environments.

Anti-static materials: Prevent stickers from attracting dust or damaging delicate components.

Flexible materials: Suitable for curved surface application (such as silicone, PVC).

- Adhesive technology

Permanent bonding: High adhesion, suitable for metal, plastic and other surfaces.

Removable adhesive: No residue adhesive left after replacement or upgrade.

Chemical resistance: Resistant to corrosion from alcohol, solvents and other cleaning agents.

- Printing and Protection

High-resolution printing: Supports small fonts and clear presentation of QR codes.

Coating/Sealing: Anti-scratch, waterproof, UV-resistant, extending the lifespan of the label.

Special techniques: Fluorescence, laser engraving, embossing and other customized effects.

Industry Compliance Requirements

The stickers must comply with international standards:

Environmental protection certification: Complies with RoHS and REACH standards, free of harmful substances.

Safety standards: UL certification, flame retardant grade (such as UL94 V-0).

Traceability: Complies with ISO 9001 and IATF 16949 quality management systems.

Customized Services

We can provide the following based on customer requirements:

Personalized designs for size, shape and color.

Variable data printing (serial numbers and batch numbers generated in real time).

Special environment adaptation (extreme temperatures, outdoor durability).

Advantages of Choosing OwnLikes

Professional Experience: With 10 years of in-depth experience in the electronic industry's tagging field, providing services to global Fortune 500 companies.

One-stop service: Full support from design, prototyping to mass production.

Fast delivery: Supports rush orders and expedited processing to ensure supply chain efficiency.