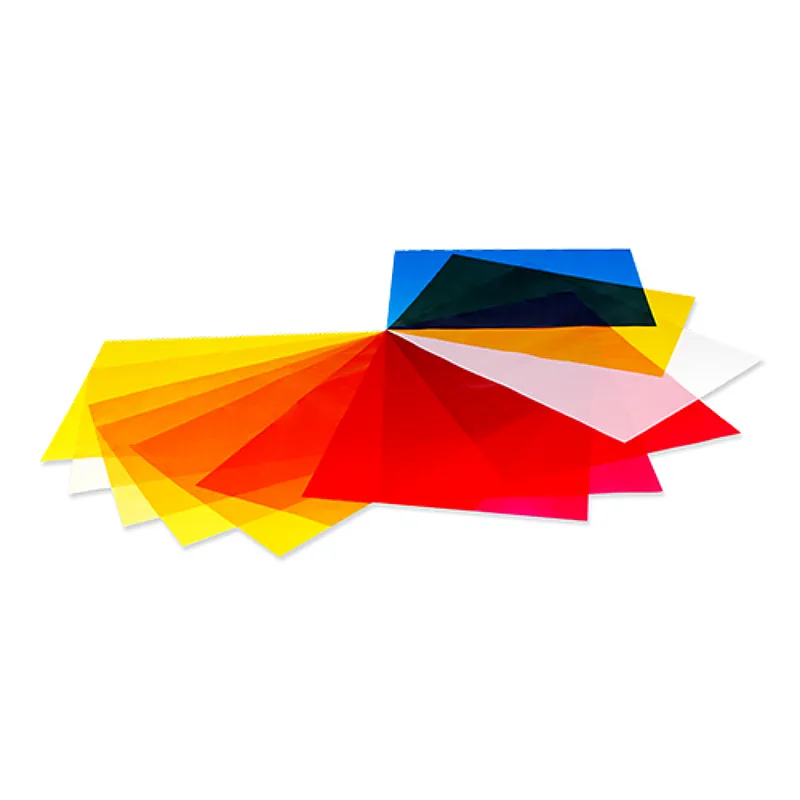

Colour biodegradable cellulose film is a revolutionary environmentally friendly packaging material. It is based on natural plant cellulose and made into a fully biodegradable high-performance film through innovative processes. The product combines bright and long-lasting colors with outstanding environmental protection features. While providing visual appeal, it completely bids farewell to plastic pollution and offers a perfect solution for sustainable consumption.

Product Review:Regenerated cellulose film is a degradable material made from natural cellulose such as wood pulp and cotton pulp. t goes through a seriesof chemical changes such as alkaization, xanthation and casting and change into another regenerated cellulose film. Compared with paperregenerated cellulose film not only has better flexibility, but also has the same transparency as glass.

Regenerated cellulose film has the advantages of non-toxic and tasteless, high-temperature resistance, anti-static, and direct contact withfood, making it widely used in fields such as food, medicine, labeling, tape, cosmetics, precision instruments, etc.

In recent vears, the global polution problem has become increasingly severe, in order to control the continuous deterioration ofthe environment, a series of environmental protection policies and requlalions have been introduced at home and abroad.

With the deepening of policiesenvironmenlal polution has become an undeniable issue and has become the focus of alobal altention foday, As a nalural and environmentallfriendly material, regenerated cellulose film can quickly degrade in soi without causing secondary pollution to the environment, it is a natural'fertilizer" that alians with today's human vision for a better living environment.With the increasing globalization of"plastic restricion", regenerated cellulose films will become the backbone of buiding a "green home" in the future.

Colour biodegradable cellulose film is a revolutionary environmentally friendly packaging material. It is based on natural plant cellulose and made into a fully biodegradable high-performance film through innovative processes. The product combines bright and long-lasting colors with outstanding environmental protection features. While providing visual appeal, it completely bids farewell to plastic pollution and offers a perfect solution for sustainable consumption.

Regular Specifications and Technical Indicators (Typical Value)

The commonly used weight range is 30g, etc The specific width and length can be negotiated with the customer.

| Item | Gran Weight/Unit | 30g | |

| Substance | g/m² | 30±1 | |

| Tensile Strength | MD | N/15mm | ≥40 |

| TD | ≥15 | ||

| Elongation | MD | % | ≥15 |

| TD | ≥40 | ||

| Antiblocking Property | 24-90RH% | ≥70 | |

| Moisture | % | 5.0-9.0 | |

All technical data is tested under laboratory standard conditions: 23 ± 2℃; 50±5% RH.

Similar Biodegradable Cellulose Film Products

Biodegradable Cellulose Film Core Advantages Characteristics:

It features high smoothness, excellent printing composite properties, accurate multi-color overprinting, anti-static properties, and small thickness and width differences. It is compatible with various printing techniques such as flexographic, gravure, and digital inkjet printing, with high color reproduction and fine, clear patterns.

Strong adhesion, the ink is not easy to smudge, ensuring that the brand logo and text information remain eye-catching for a long time.

Derived from plant cellulose (such as wood pulp, agricultural waste), it is completely decomposed within 180 days under industrial composting conditions to generate water, carbon dioxide and organic fertilizer (conforming to ASTM D6400 / EN 13432 standard).

Zero microplastic residue, return to nature without burden.

High transparency (≥90%), flexible and foldable, strong tear resistance, suitable for various packaging forms.

Excellent oxygen barrier property, extending the shelf life of sensitive products such as food and cosmetics.

Customizable thickness (20-100μm) and surface treatment (matte/glossy) to meet the requirements of different scenarios.

The raw material is food-grade cellulose and has passed the FDA and EU 10/2011 food contact material safety certifications.

Free of plasticizers and heavy metals, it is naturally anti-static, protecting the health of both the product and consumers.

Biodegradable Cellulose Film Application Scenarios

Food packaging: snack bags, tea bags, baking linings, fresh food trays with film coating

Cosmetics & Personal care: Mask base cloth, label stickers, outer layer of skin care tube

Cultural and creative printing: eco-friendly book covers, gift wrapping paper, degradable labels

Agricultural field: Seed belts, degradable seedling bags

Others: Medical dressing base materials, industrial cushioning packaging

Biodegradable Cellulose Film Technical Parameters

Attribute: Numerical value/Characteristic

Raw Material: Natural plant cellulose

Thickness Range :20-100 μm (Customizable)

Tensile Strength :≥40 MPa (longitudinal)

Degradation Conditions: Industrial composting (temperature 58±2°C, humidity 50-60%)

Printing Compatibility: water-based /UV ink, heat transfer printing, digital inkjet printing

Transparency :≥90%

Operating Temperature :-20°C to 120°C

Biodegradable Cellulose Film Value Proposition:

Biodegradable cellulose film is not merely a packaging material; it is a strategic choice for you to fulfill your brand's environmental commitment, meet consumers' green demands, and actively address the global plastic pollution challenge. It integrates high performance, safety, aesthetics and ultimate environmental responsibility, providing you with a complete sustainable packaging solution from "cradle" to "return to the soil", and helping to build a cleaner and greener future.

Choose OwnLikes, choose the power of nature, choose a responsible future.

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(1)

The Colour Biodegradable Cellulose Film is such a fantastic material! It’s got a unique feel and really stands out. Feels good to use something eco-friendly that also looks this great.