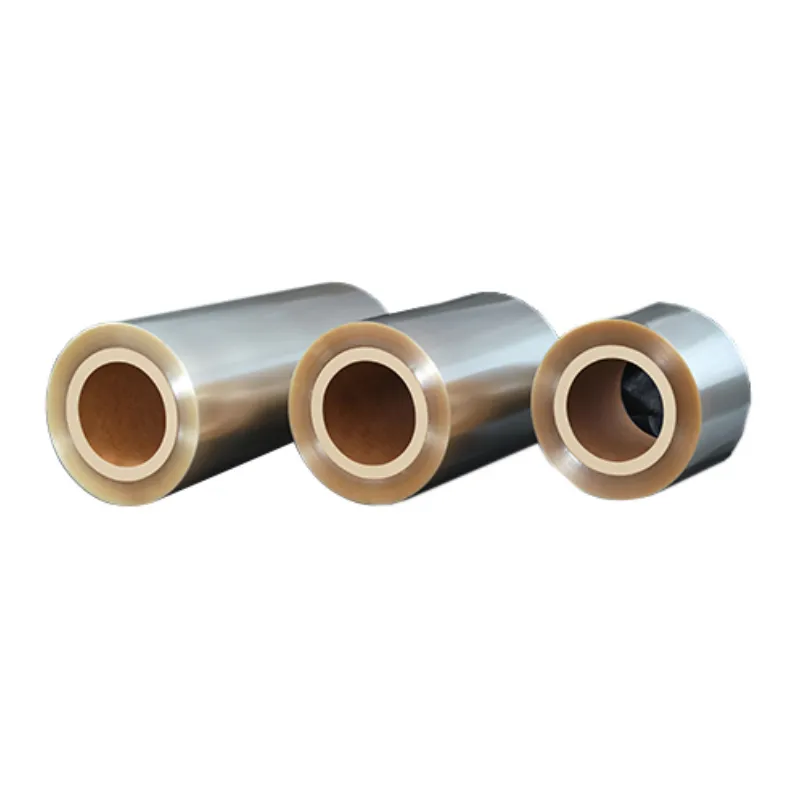

Semi-barrier regenerated cellulose film is a high-performance and sustainable transparent packaging film, made from natural wood pulp through advanced technology. It perfectly combines the outstanding optical performance, excellent mechanical strength and natural biodegradability of traditional regenerated cellulose membranes (such as cellophen), and significantly enhances its barrier performance against oxygen, aroma and oil for specific application requirements, reaching a "semi-barrier" level. This film represents the ideal balance between eco-friendly packaging and functional requirements.

Product Review:Regenerated cellulose film is a degradable material made from natural cellulose such as wood pulp and cotton pulp. t goes through a seriesof chemical changes such as alkaization, xanthation and casting and change into another regenerated cellulose film. Compared with paperregenerated cellulose film not only has better flexibility, but also has the same transparency as glass.

Regenerated cellulose film has the advantages of non-toxic and tasteless, high-temperature resistance, anti-static, and direct contact withfood, making it widely used in fields such as food, medicine, labeling, tape, cosmetics, precision instruments, etc.

In recent vears, the global polution problem has become increasingly severe, in order to control the continuous deterioration ofthe environment, a series of environmental protection policies and requlalions have been introduced at home and abroad.

With the deepening of policiesenvironmenlal polution has become an undeniable issue and has become the focus of alobal altention foday, As a nalural and environmentallfriendly material, regenerated cellulose film can quickly degrade in soi without causing secondary pollution to the environment, it is a natural'fertilizer" that alians with today's human vision for a better living environment.With the increasing globalization of"plastic restricion", regenerated cellulose films will become the backbone of buiding a "green home" in the future.

Semi-barrier regenerated cellulose film is a high-performance and sustainable transparent packaging film, made from natural wood pulp through advanced technology. It perfectly combines the outstanding optical performance, excellent mechanical strength and natural biodegradability of traditional regenerated cellulose membranes (such as cellophen), and significantly enhances its barrier performance against oxygen, aroma and oil for specific application requirements, reaching a "semi-barrier" level. This film represents the ideal balance between eco-friendly packaging and functional requirements.

Regular Specifications and Technical Indicators (Typical Value)

The commonly used weight range is 30g, etc The specific width and length can be negotiated with the customer.

| Characteristic | Test Method | Unit | DOUBLE-BIO-RCM-MK-FILM | ||

| 350 | 500 | ||||

|

Substance |

OwnLikes Testmethod |

g/m² | 35 | 50 | |

| Thickness | OwnLikes Testmethod | um | 23 | 33 | |

| Water Vapor Permeability | ASTM E 96 | g/m².24h | 200-900 | ||

| Coefficient Offriction | ASTM D 1894 | Static/Dynamic | 0.4 / 0.28 | ||

| Tensile Strength | ASTM D 882 | N/15mm | MD | 57 | 73 |

| TD | 31 | 39 | |||

| Elongationat Break | ASTM D 882 | % | MD | 18 | 18 |

| TD | 41 | 42 | |||

| Heat Seal Temperature Range |

OwnLikes Testmethod |

℃ | 120-160 | ||

| Heat Sealing Strength |

OwnLikes Testmethod 120°C, 0.07Mpa 1 second |

g/37mm | 595 | ||

| N/15mm | 2.36 | ||||

All technical data is tested under laboratory standard conditions: 23 ± 2℃; 50±5% RH.

Similar Biodegradable Cellulose Film Products

Biodegradable Cellulose Film Core Advantages Characteristics:

Oxygen barrier (OTR) : Significantly superior to standard regenerated cellulose membranes, it can effectively slow down the oxidation and deterioration of the contents, and extend the shelf life and flavor stability of foods (such as dried goods, nuts, baked goods, some candies, and cheeses).

Aroma barrier: It can effectively lock in the inherent aroma of the product and prevent the invasion of external odors, maintaining the pure flavor of the product.

Oil barrier: It offers excellent oil-proof performance and is suitable for foods with moderate oil content (such as biscuits and fried snacks) as well as some cosmetics and personal care products, preventing oil stains from seeping out and contaminating the packaging.

Renewable raw materials: The main raw material is sustainably managed forest wood pulp, which is a renewable resource.

Biodegradable & compostable: It can be completely biodegraded under industrial composting and household composting conditions, eventually converting into water, carbon dioxide and biomass, significantly reducing plastic pollution and landfill burden.

Non-plasticized: Free of plastic micro-particles, it avoids long-term harm to the environment.

Transparency & High Gloss: With crystal-like transparency and high gloss, it perfectly showcases the product's appearance and enhances the shelf's appeal.

High strength and toughness: It has excellent tensile strength and tear resistance (especially in a wet state), ensuring reliability during processing and transportation.

Dimensional stability: Maintain stable dimensions under normal temperature and humidity conditions to reduce the risk of packaging deformation.

Heat sealing property (usually requiring coating) : It can be combined with suitable coatings (such as nitrocellulost, PVDC, acrylic or bio-based coatings) to achieve reliable heat sealing and meet the requirements of automated packaging. The selection of coatings has also further optimized its barrier performance.

Good printability: The surface is easy to be printed in high quality, presenting bright colors and clear patterns.

Maintaining the relatively high water vapor transmission rate inherent in regenerated cellulose membranes (compared to high-barrier plastic membranes) is beneficial for products that require "breathing" to prevent condensation or maintain specific humidity, such as fresh produce and some baked goods. This is also one of the reasons why it is defined as "semi-barrier" rather than "high-barrier".

Biodegradable Cellulose Film Application Scenarios

It can be applied to single-layer direct packaging, or the overall wrapping or sealing packaging of objects after compounding. For example,31-35g/n can be used for cigarette packs, non-load-bearing dry gift bags, accessory packaging, etc., and can also be used for food packaging bags or the inner layer oxygen barrier layer of multi-layer composite materials. 45-60g/㎡ can be used for cigar packaging, food baking bag making, snack, candy, grain food packaging, clothing, labels (white opaque label film can be customized), and envelope Windows, etc.

Biodegradable Cellulose Film Specification parameters (example, specific details need to be confirmed according to the product model) :

Thickness range: typically 28-45 micrometers (μm) or 1.1-1.8 mil

Oxygen transmission rate (OTR) : Approximately within the range of 10-100 cc/m²/day/atm (23°C, 0%RH), significantly lower than that of standard regenerated cellulose membranes (typically > 1000), but higher than that of high-barrier materials such as EVOH (< 1).

Water vapor transmission rate (MVTR) : approximately 300-1000 g/m²/day (38°C, 90%RH), which is higher than that of high-barrier plastic films.

Tensile strength (MD/TD) : High, with specific values depending on thickness and grade.

Elongation at break (MD/TD) : Moderate.

Glossiness: Extremely high (> 80%).

Haze: Very low (< 2%).

Application

Food packaging

Non-food packaging

Biodegradable Cellulose Film Value Proposition:

Biodegradable cellulose film is not merely a packaging material; it is a strategic choice for you to fulfill your brand's environmental commitment, meet consumers' green demands, and actively address the global plastic pollution challenge. It integrates high performance, safety, aesthetics and ultimate environmental responsibility, providing you with a complete sustainable packaging solution from "cradle" to "return to the soil", and helping to build a cleaner and greener future.

Semi-barrier regenerated cellulose film is designed for packaging solutions that seek sustainability, excellent product display effects and targeted functional protection. It transcends the limitations of standard regenerated cellulose membranes, providing effective protection for products that are prone to oxidation, require fragrance retention or contain oils, while adhering to its core environmental commitment of being biodegradable and derived from nature. It is an ideal choice for brands to enhance their environmental protection image, meet consumers' green demands and ensure product quality.

Choose OwnLikes, choose the power of nature, choose a responsible future.

Usage Tips:

The specific barrier properties (oxygen, water vapor, aroma, oil) may vary depending on the base film formula, coating type and thickness. When making a selection, it is necessary to match the specific application requirements.

Its excellent oxygen barrier property is optimal under dry conditions. A high humidity environment may have a certain impact on its oxygen barrier property (but it is usually still better than standard regenerated cellulose membranes).

Applications that require heat sealing must select models with appropriate heat sealing coatings.

This description can be fine-tuned according to the specific product brand, target market and application focus.

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(1)

This semi-barrier heat-sealing regenerated cellulose film works well. Good clarity, seals tightly with heat, and offers decent protection. Eco-friendly plus, which we love. Worth it for our packaging needs.