Clear Biodegradable Cellophane Tape are products made of cellulose paper and glue; It has the functions and characteristics of traditional plastics, and can be degraded under natural conditions (such as soil, sand, sea water, etc.) or under specific conditions (such as composting conditions, anaerobic digestion conditions or water-based culture solution, etc.) by microbial action (such as bacteria, mold, fungi, algae, etc.) after reaching the service life. And eventually completely degrade into carbon dioxide, water, methane, mineralized inorganic salts.

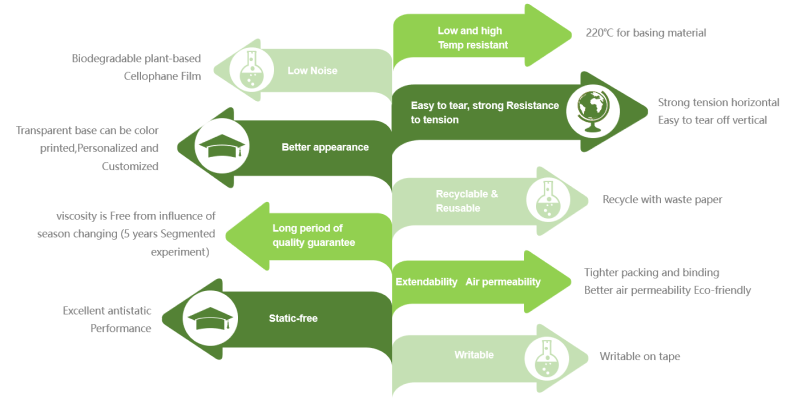

Product Review:Biodegradable Cellophane Tape: The basing material of this product is called “cellulose film” which is a kind of natural materials. Cellulose film is made from cotton pulp or wood paddle as raw material and regenerated cellulose membrane after special processing. It is different from ordinary paper. It is not only flexible, but also transparent, just like glass, so it is called "cellophane". It is different from ordinary paper. It is not only flexible, but also transparent, just like glass, so it is called "cellophane". Environmental friendly pressure-sensitive glue, both biodegradable and water-based, is emulsified with butyl acrylate, water, rosin resin and additives. It can be biodegraded into water and carbon dioxide, and can be recycled together with waste cartons. It can be colored as required, such as white, red, blue, coffee, beige, etc. it can print various logos and customize different specifications as required.

"About 80 billion pieces of clothing are manufactured every year, and 90 percent of them use plastic to fix price tags and product information labels. The main driving force behind this innovation is the growing emphasis on environmental protection and sustainability in the apparel market among brands, retailers and consumers, and we will continue to develop more eco-label solutions in the future."

In the post-pandemic era, new consumer demand is taking shape, and a new consumption structure is accelerating. People are paying more attention to maintaining a healthy and strong body, and paying more attention to the safety, comfort and environmental sustainability of clothing itself. The epidemic has made people more aware of human vulnerability, and more and more consumers have more expectations for brands in terms of environmental protection and social responsibility.

OwnLikes offers integrated solutions for cellulose paper films, bio-based materials, degradable films, moisture barrier coatings and a wide range of high performance pressure sensitive adhesives Excellent fibers and films with roughly the same strength as nylon and polyester fibers.

In order to meet the requirements of sustainable development/circular economy/environmental deplasticizing in the packaging market, our company combines advanced technology at home and abroad to develop Cellulose paper film product OL008.

• The raw material is wood pulp fiber, derived from sustainable forest resources

• Biodegradable and sustainable product life cycle

• High transparency, good tensile strength • Innovative coating process to enhance printability and moisture resistance

• FSC Certification (Certificate No. RINA COC-001475)

• SGS Biodegradation Certification (ISO Certificate No. : GZIN2111064903MR)

Market Demand Matching/Sustainable Development/Circular Economy Recycle

Recycling: The raw material of the product comes from the recycled ingredient Renew

Renewable Resources: The raw materials of the products are derived from biomass resources, such as forests, plants, etc., rather than oil reduction

Reduction: product thinning, weight reduction, plastic reduction, the use of less raw materials, monomer structure instead of composite structure Degrade

Degradable: biodegradable, industrial degradable, oxygen degradable, photodegradable

About Custom :

OwnLikes can provide customized processing of various materials and surface material weight selection, dyeing, laser shading, inkjet coating and other processes.

OwnLikes can provide glue coating selection: custom processing of water glue, hot melt glue, oil glue, removable glue and other processes.

OwnLikes can provide customized processing such as printing LOGO on release paper and choosing the thickness of release paper.

According To Customer's Adhesive Needs Can Be Customized, There Are Three Schemes

1、biodegradable cellulose paper film (thickness of any 25-40u) + water glue + substrate (according to customer requirements, grid or transparent bottom)

2、 biodegradable cellulose paper film (thickness of any 25-40u) + oil adhesive (according to customer requirements, grid or transparent bottom)

3、 biodegradable cellulose paper film (thickness of any 25-40u) + movable adhesive (according to customer requirements, grid or transparent bottom)

About Customization

1. Size specifications can be selected

2, can be printed LOGO pattern

4, can be customized automatic labeling roll material, cutting, etc

Q: Your material is visually indistinguishable from membrane. What quick way to verify that it is not membrane?

A: Three quick verification methods:

1 Ignition: In a safe environment, ignite it: fast combustion, no dripping, residue is paper ash

2 Smell: The smell of burning paper products is the same

3 Tear: longitudinal easy to tear.

PS: She is a transparent paper, not a plastic film

Q: Are there any supporting documents? What are they?

A: We have completed multiple tests and certifications, and obtained certificates:

1. Eu Industrial Composting Certificate

2. Eu Home Composting Certificate

3.FSC Forest Certificate

4.Rohs report

5.FDA food grade certification

6. Halogen reports

Q:If it's paper, is it moisture-proof?

A: Moisture-proof

Q: What tests were done? Which post-process is it suitable for?

A: We through the special process, after numerous rigorous tests: finally at 60% high temperature and 85% high humidity, 48 hours in a confined space and at the same time through the coating, shallow bump, shallow embossing, UV, gold, screen printing, pressure wire, high frequency heat sealing bag, drop test in color box packaging, handbags, books, labels and so on successfully completed

Q: Since it can be completely degraded in more than 90 days, will the finished product be degraded before it reaches the customer's hands?

A: This question is very imaginative, please don't worry! Degradation requires a specific, sustained stay in the same environment for more than 90 days, requiring microorganisms, temperature and humidity, etc., to degrade

Q: What are the special advantages compared with OPP/PET films?

A: 1. Biodegradable

2. with antistatic function

3. the corona value after stability is not less than 41 Dahn value

4. high transparency, good color reproduction

5. Strong rupture resistance

6. high barrier

7. odorless and non-toxic after burning

8. Easy to tear longitudinally. Meet special needs

9· The same thickness is high in width

10. Fully meet customer environmental protection needs. Free from tariffs under the plastic order and contribute to creating a better home!

Q: What is the residue after degradation?

A: Sunsong ECM biodegradable materials are converted into harmless substances such as protein and glucose after degradation.

Can imagine a beautiful picture, in the beautiful seashore, when we swim in the sea · no longer have to worry about meeting: 100 years will not decompose the plastic bag; No longer have to worry about sea creatures mutating or even dying from eating plastic.

Q: Can your products be recycled?

A: When sunsongECM regenerates degradable cellulose materials, the proportion of finished products is not more than 20%, no separation processing is required, and it can be recycled together with paper.

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(2)

I’ve used the Biodegradable Cellophane Tape, and it’s great for everyday use. It sticks well and feels just like regular tape, but it’s better for the environment. Nice to have an eco-friendly option that actually works.

Used the Biodegradable Cellophane Tape for gift wrapping—it holds well and looks just like regular tape. Nice to know it breaks down over time. A small switch, but feels like a better choice for the environment.