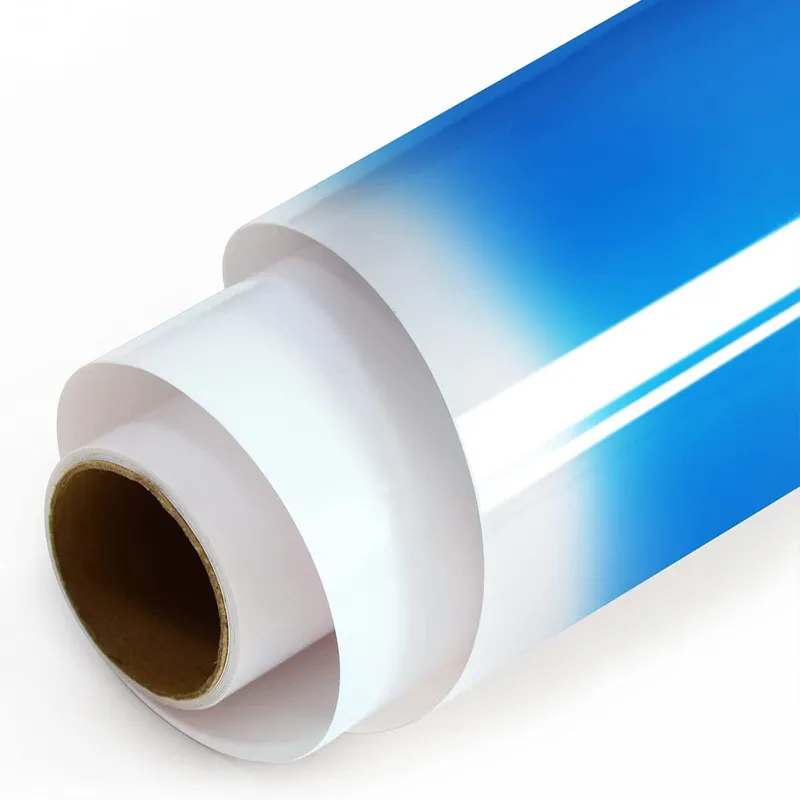

The appearance of the film changes color after contact with the object with temperature, and the original color is restored after cooling, which is also often called the temperature-sensitive thermochromic lettering film.

The appearance of the film changes color after contact with the object with temperature, and the original color is restored after cooling, which is also often called the temperature-sensitive thermochromic lettering film.

The film is mainly composed of color-changing dye, color developing agent and solvent, PVC film and glue. At high temperature, the color-changing dye and color developing agent dissolve and disperse in the solvent, and the system presents a white state. When the temperature decreases, the solvent gradually solidifies, the color-changing dye and the color developer are close to each other, and the structure of the color-changing dye changes under the action of the color developer, so that the system shows color. By adjusting the solidification temperature of the solvent, the thermotropic products that change color at different temperatures can be prepared.

Temperature Change Lettering Film Characteristics:

1、The essence of the discoloration process is physical heating and chemical reaction discoloration process, with reversibility, the number of cycles can reach thousands of times!

2、 Strong bonding, precise connection with the material, not easily degumming!

3、 UV resistance is good, long-term exposure to the sun will not lead to brittleness and discoloration disorders!

4、Washable and kneading resistance, normal machine wash hand wash, do not worry about damage to discoloration material can not change color!

5、 Stable coloring, environmental protection and non-toxic, all materials are harmless to the human body!

6、 Good elasticity, can be used in sports clothing with high elasticity requirements

7、Easy to cut, easy to carve, after stamping edge delicate and clear, good appearance!

Temperature Sensitive Color-changing Adhesive Material

Temperature change lettering film application

The film can be matched with laser cutting, marking, engraving machine and other equipment to cut it into patterns, graphics, text, letters, lines, etc., mainly used in the clothing industry.

Temperature change lettering film can bring more possibilities to clothing, hot environment, indoor it is calm black, go to the sun is gorgeous color, seamless switch a variety of styles, giving people a unique experience!

Storage Period:

Cool and ventilated at room temperature, avoid sunlight, the temperature is 25±3℃, the relative humidity is 50±5%, the use of well-sealed and moisture-proof packaging, the shelf life can be up to 12 months.

Applications:

Such as pipeline identification, direction arrow labeling, warehouse identification, warning signs, safety signs, power signs and so on. Strong adhesive, suitable for pipes, walls, equipment, Windows and other most clean and dry surfaces; It is also suitable for curved, rough and other irregular surfaces, and can even resist oil and most industrial chemicals. This material can also be used indoors.

Others:

Acrylic water-based pressure sensitive adhesive, suitable for adhesive substrates: various paper, film, steel, glass, glue products, etc. If the customer needs to paste on PP or PE, it should be tried in the corresponding environment first. Not suitable for pasting under -5 ° C.

Instructions for Use:

All descriptions of OwnLikes materials are based on our current knowledge and the results of repeated testing. Customer in the use and production process, there are other external factors, resulting in the impact of the product, the company will not bear the consequences. Therefore, we recommend that customers conduct various tests in the application environment before using. The range of our refund will not exceed the selling price of the corresponding material. Our company has the right to technical improvement and final interpretation.

If you have any questions about our head Stickers material products, please feel free to contact us.