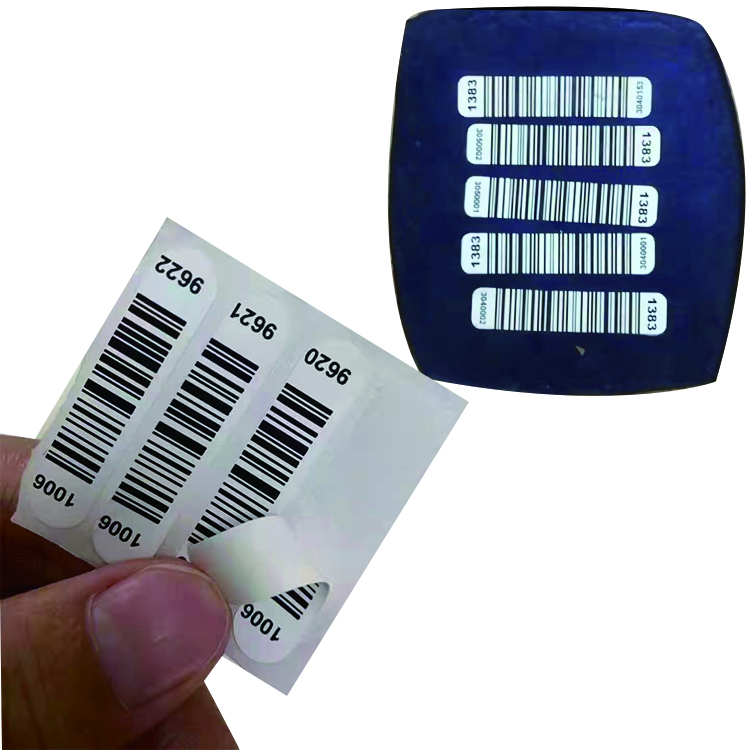

OwnLikes is specifically designed for all-steel tire barcode and tire number etching applications, and consists of a permanent rubber-based glue that is resistant to high temperatures and vulcanized with the tire for the entire life cycle of the tire. Features: • Excellent high temperature stability, withstand the heat and pressure of the tire when it is treated with high temperature and sulfur (up to 210℃) • Excellent durability and wear resistance • Excellent chemical resistance: strong water resistance, acid resistance, salt, alkali, most oil stains, oil and low-fat solvents, adhesives can penetrate into the concave surface, firmly combined with the tire surface penetration softener, when the car in the running bar code will not fall off, at the same time, artificial forced peeling will not destroy the tire surface rubber • Excellent barcode/heat transfer printing effect, with VR-30 carbon belt, to ensure 100% accurate reading and scanning on the high-speed transmission line before and after vulcanization. • Excellent adhesion: When the tire is removed from the mold, strong flexibility to withstand tire deformation

Product Review:Small Size..... But Powerful

Each tire manufacturer has its own different production process,But what they have in common is that they all need us to provide labels to help them trace the production process.

This tire label is designed for different vulcanization processes, it super stable performance will not disappoint.

Wear resistance - After a harsh vulcanization process, the bar code on the label still legible.

The bar code is readable throughout the life cycle of the tire. In a day by labeling it, it won't be scratched off and doesn't need to be labeled again.

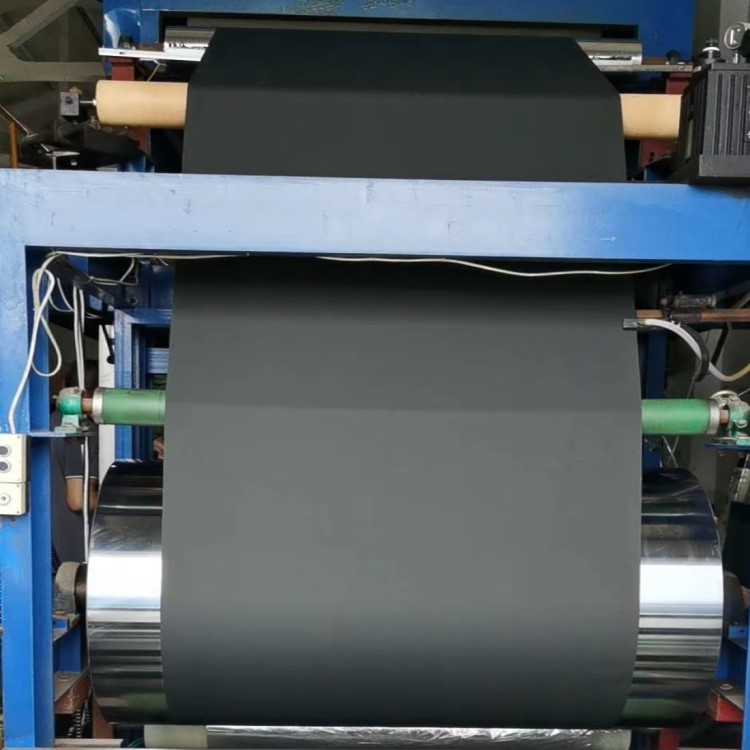

To reduce downtime, label materials and adhesives can be made from dynamic labeling machine or marking machine seamless operation, to maintain the continuous operation of the production line. No duplicates, a fixed quality inspection system will help detect any duplicate bead labels.

Vulcanization Purpose:

Through external shear, high temperature promotes the chain molecules in the rubber to cross-link into a network molecule, strengthening its tensile force, hardness, aging, elasticity and other properties to make it more valuable. In the vulcanizer, the tire will be at a high temperature of more than 145 degrees Celsius, depending on the size, the vulcanization time will vary to form the final shape and tread pattern. A hot die shapes and hardens the tire. When the machine is turned on, the tire will roll out of the mold and be sent through a long conveyor belt for final inspection.

What makes our products different?

Our labels are professionally designed.

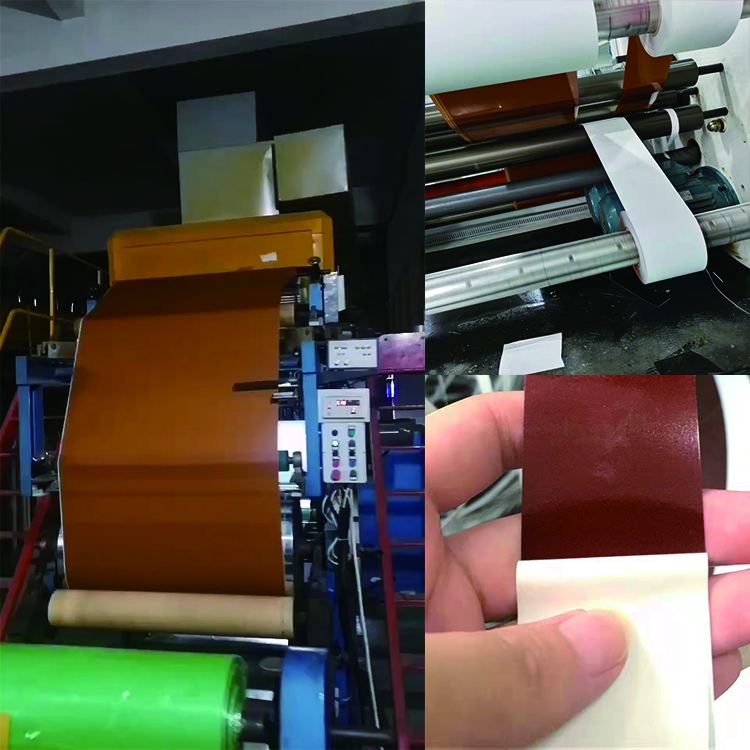

Our labels are made of our own blended adhesives. This means that we know exactly what constitutes the label, the adhesive help us glue the different layers together to produce labels that fit our needs. This label is particularly important for its significance suitable for different tire production processes and tire materials

The significance of vulcanization label in tire industry:

After the tire is formed, the barcode label is affixed to it and vulcanized so that it is kept throughout the life of the tire, and the production date, installation date and service date of the tire are fed back at any time, thus providing reliable raw data for quality assessment.

| Trait | Advantage |

| OwnLikes professional label materials and glue | High quality labels, after the vulcanization process, the barcode reading rate is very high |

| Labels are designed according to the customer's reading technology | Single-source inventory selection in the stock keeping Unit helps you plan your production needs |

| Custom shapes, pictures, design drawings | Make sure labels are kept intact during harsh deliveries and shipping |

| Global procurement | We try to make products to meet the needs of all factories, reduce your procurement costs |

| Precise location and traceability of the production process | The productivity of tyre factories requires OwnLikes reliable barcode traceability technology |

If there is any demand, please leave a message to inform the tire production cheng, we will produce suitable samples as soon as possible.

Order Size:

Reference Size: 530*500m (coil), 30mm*6mm 38mm*8mm 40mmX10mm and other specifications of die cut and prefabricated bar code coil

Certification: Rohs, halogen free

L/T: 10 days, according to the actual customization requirements

Regular Product Information:

| P/N | Materials | Thickness μm | Release Paper | Printing Mode | Temperature Resistance | Ribbon | Peculiarity |

| VL-75 | 75μPET | 100±10 | PET | Thermal transfer/Printing | 200℃ | VR-35 | Suitable for motorcycle tires |

| VL-100 | 100μPET | 125±10 | PET | Thermal transfer/Printing | 200℃ | VR-35 | Be common |

| VL-125 | 125μPET | 155±10 | PET | Thermal transfer/Printing | 200℃ | VR-35 | Be common |

| VL-250 | 250μPET | 270±10 | PET | Thermal transfer/Printing | 200℃ | VR-30 | Laser etching |

| VL-H50 | 50μPI | 70±10μ | PET | Thermal transfer/Printing | 200℃ | VR-30 | Vulcanized capsule |

Alternative Product Information:

| P/N | Materials | Adhesive | Release Paper | Printing Mode | Temperature Resistance | Ribbon | Labeling method | Fungible |

| VL-75 | 75μPET | 100±10 | Glazin paper | Thermal Transfer | 200℃ | VR-35 | Manual/Automatic | Kuramoto |

| VL-100 | 100μPET | 125±10 | PET Film Base | Thermal Transfer | 200℃ | VR-35 | Manual/Automatic | Computype |

| VL-125 | 125μPET | 155±10 | PET Film Base | Thermal Transfer | 200℃ | VR-35 | Manual/Automatic | United States /DATA 2 Hochang, Taiwan |

| VL-250 | 250μPET | 270±10 | PET Film Base | Thermal Transfer | 200℃ | VR-30 | Manual/Automatic | Nitto, Japan |

| VL-H50 | 50μPI | 70±10μ | Glazin paper | Thermal Transfer | 200℃ | VR-30 | Manual/Automatic | Japanese Linderaceae |

The combination of barcode machine printing and scanning gun recommended by OwnLikes constitutes a complete tire quality traceability system, providing the perfect tire vulcanization process tracking management solution the curing time of the manufacturers is different. Affected by the size, pattern type, vulcanization temperature, compound formula, tire structure and other factors, semi-steel car tires are generally 9-30 Minutes, the whole steel is generally 45-60 minutes, according to the size of the tire and vulcanization process to decide, please be sure that the customer to do field testing.

The specific price is determined according to the size of the label, the pattern, and the quantity ordered. Please consult your OwnLikes local sales and technical support team.

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(1)

Used the 300um Vulcanized Rubber Label Material for custom product labels. The material is thick and durable, with great adhesive strength. It holds up well even in tough environments, like high temperatures. A solid choice for heavy-duty labeling.