Say goodbye to traditional labels that are prone to wear, fading or peeling! OwnLikes' laser etched labels utilize high-precision laser technology to permanently mark the material surface directly, creating clear, sharp and indelible identifiers. This non-contact and consumable process provides your products with a lifetime traceable identity proof, maintaining excellent readability even in the harshest environments.

Product Review:A leading supplier of specialty labels for industrial applications recently introduced a cost-effective alternative to laser marking, engraving or etching and found that polyphenylene sulfone (PPSU) films are suitable for Structobond labels for medical device and device applications. PPSU films are sandwiczed between layers of S+P Samson's epoxy material, a thin, tough strip with very good vapor and gamma-sterilization compatibility, strong chemical resistance, and high contrast of imprinted data for improved product identification and surgical instrument traceability.

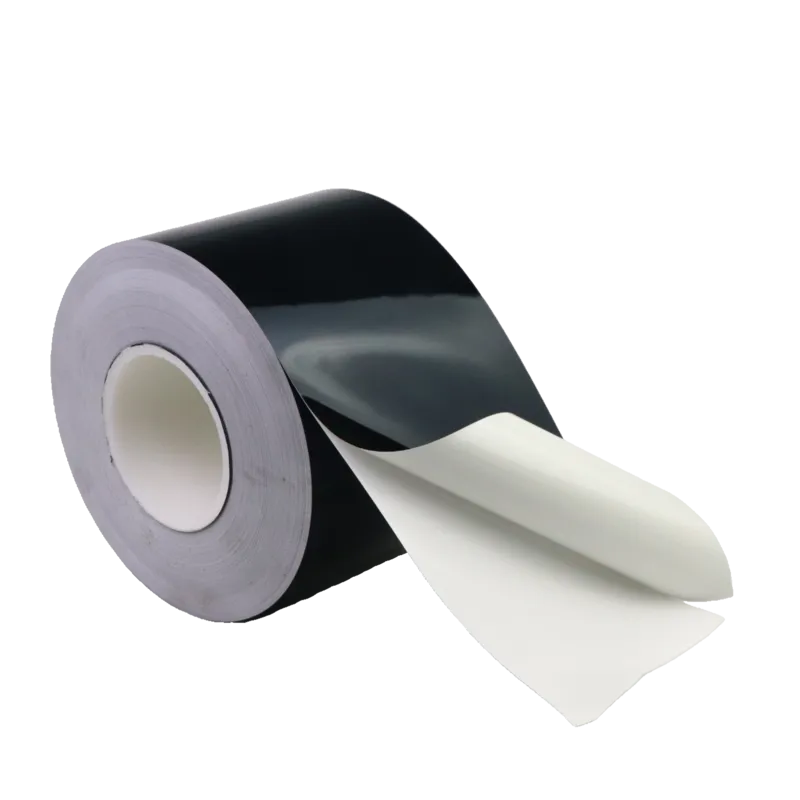

The laser-etched label material is a specialty 2.4 mil matte black/white acrylic face paper coated with 1.2 mil 350 permanent acrylic adhesive on 55 pounds of dense craft paper board. Thin film label material, the laser can ablate the top layer of the double layer material to form a certain pattern. The same laser also allows labels to be semi-perforated to specific sizes, increasing the flexibility to manufacture a wide range of durable labels.

Double acrylic paper can be laser etched. Excellent temperature resistance, chemical resistance and environmental resistance. Good bonding properties on many substrates, including low surface energy plastics. The fragile face paper is easily removed after being attached to some substrate. UL and CSA certified laser marking paper used in nameplates has excellent durability, resistance to automotive chemicals and wear resistance.

Core advantage

Laser etching directly forms physical indentations on the material surface or changes the color of the coating. The patterns and characters will never fade, fall off or become blurred.

Outstanding weather resistance: Resistant to harsh environmental challenges such as ultraviolet rays, high and low temperatures, humidity, chemical corrosion, and solvent wiping, suitable for long-term use both indoors and outdoors.

Outstanding scratch resistance and wear resistance: The surface markings are not easily scratched or worn off, ensuring long-lasting clarity and legibility.

Laser beams can be precisely controlled to achieve micron-level precision in detail engraving, easily presenting fine lines, tiny characters, complex graphics and barcodes (including high-density QR codes), ensuring high readability.

The edges are sharp and clear, with high contrast (usually a dark mark is formed on a light background after etching, or vice versa), and excellent visual recognition.

No ink or printing plates required: Eliminating the traditional printing processes such as plate making, ink mixing, and cleaning, it reduces material waste and chemical usage, making it more environmentally friendly.

Instant variable data: Seamlessly integrated with digital laser systems, it easily enables real-time online variable marking of information such as serial numbers, unique codes, and date batches, with extremely high efficiency.

Fast processing: Laser engraving is fast, especially suitable for small-batch, multi-batch or immediate marking scenarios.

High-quality base materials: Durable polyester film (PET) or special synthetic paper is usually used as the base material, providing excellent dimensional stability, tear resistance and temperature resistance.

Strong adhesive: Equipped with industrial-grade permanent adhesive, it ensures strong adhesion, high initial adhesion and long-lasting bonding firmness on various smooth and clean surfaces (such as metal, plastic, glass, coated surfaces).

Strong temperature resistance: The base material and adhesive can usually withstand a wide temperature range (such as -40°C to +150°C or higher, depending on the model), making it suitable for high-temperature application environments.

It is applicable to a variety of hard materials: metals (stainless steel, aluminum, titanium, copper alloys, etc.), hard plastics (ABS, PC, PEEK, nylon, etc.), ceramics, glass, and some coated/anodized surfaces.

It offers a variety of effects such as deep engraving (clear indentation), shallow engraving (surface color change), and even color marking (for specific materials).

Non-contact process: No physical pressure, no damage to the material matrix.

No consumables: No ink, ribbons, stickers or chemical reagents are needed, significantly reducing long-term operating costs and being more environmentally friendly.

High-speed automation: Easy to integrate into automated production lines to achieve high-speed, large-scale, and consistent marking operations.

Marking is part of the material itself and is extremely difficult to be tampered with or forged, enhancing product security.

It is applicable to key components, medical devices, aerospace components, etc. that require anti-counterfeiting and traceability.

Other types of laser etched label materials

Typical application scenarios

Industrial manufacturing: Equipment nameplates, tool identification, pipeline and valve marking, mechanical parts traceability.

Automotive and aerospace: Engine parts, Chassis number (VIN), wiring harness labels, high-temperature resistant/oil stain labels.

Electronics and electrical engineering: PCB board identification, component traceability, shell labels (solvent-resistant cleaning).

Medical devices: surgical instruments, implants, equipment labels (resistant to repeated high-temperature and high-pressure sterilization and disinfection).

Energy and outdoor equipment: Solar panels, battery modules, instruments and meters (weather resistance).

High-end consumer goods: Limited edition serial numbers, brand logos (enhancing texture and permanence).

Technical features:

Process type: Fiber laser, CO2 laser (select the optimal solution based on the material).

Marking contents: text, serial number, batch number, date Code, one-dimensional/two-dimensional code (DataMatrix, QR Code), Logo, graphics.

Accuracy: Sub-millimeter level accuracy, supporting ultra-small fonts and fine patterns.

Speed: High-speed marking, meeting the production line rhythm requirements.

Customization: The size, shape, marking content, depth and effect can be customized according to customer requirements.

Why choose our laser etched labels?

We possess advanced laser equipment and professional process knowledge, and are committed to providing customers with the most reliable, highest-quality and most cost-effective permanent marking solutions. From material selection consultation to marking effect optimization, we offer comprehensive support to ensure that your labels perfectly meet application requirements and enhance product value.

Give your key products an unbreakable identity!

[Contact us Now] Get samples or customize your laser etching label solution!

Usage Tips

Parameters such as laser power, speed and frequency need to be optimized and tested according to the specific material model and laser equipment.

A small amount of smoke may be produced during engraving. It is recommended to operate in a well-ventilated environment or with a ventilation device.

Make sure the pasting surface is clean, dry and free of oil stains.

This description highlights the core features that distinguish laser-etched self-adhesive labels from ordinary printed labels: permanence, weather resistance, high precision, ink-free environmental friendliness, and suitability for variable data. You can further refine and supplement based on your specific product parameters (such as base material color, thickness, specific temperature resistance value, compliance with standards, etc.).

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(1)

I used the 120mic Black Laser Etched Label Material and it works really well. The quality is consistent and it’s easy to apply, making it a dependable choice from this shop.