Precision Laser etching protective tape is a special shielding and protective material specially designed for high-precision laser etching/engraving processing. It adopts advanced polymer substrates and special adhesive formulas, providing excellent shielding protection and clear etched contours for the non-target areas of the processed workpiece while withstanding the impact of high-energy laser beams.

Product Review:A leading supplier of specialty tape for industrial applications recently introduced a cost-effective alternative to laser marking, engraving or etching and found that polyphenylene sulfone (PPSU) films are suitable for Structobond labels for medical device and device applications. PPSU films are sandwiczed between layers of S+P Samson's epoxy material, a thin, tough strip with very good vapor and gamma-sterilization compatibility, strong chemical resistance, and high contrast of imprinted data for improved product identification and surgical instrument traceability.

The laser-etched tape material is a specialty 2.4 mil matte black/white acrylic face paper coated with 1.2 mil 350 permanent acrylic adhesive on 55 pounds of dense craft paper board. Thin film tape material, the laser can ablate the top layer of the double layer material to form a certain pattern. The same laser also allows tape to be semi-perforated to specific sizes, increasing the flexibility to manufacture a wide range of durable labels.

Double acrylic paper can be laser etched. Excellent temperature resistance, chemical resistance and environmental resistance. Good bonding properties on many substrates, including low surface energy plastics. The fragile face paper is easily removed after being attached to some substrate. UL and CSA certified laser marking paper used in nameplates has excellent durability, resistance to automotive chemicals and wear resistance.

Product Name: PrecisionLaser EtchGuard Tape

Product Overview

Precision Laser etching protective tape is a special shielding and protective material specially designed for high-precision laser etching/engraving processing. It adopts advanced polymer substrates and special adhesive formulas, providing excellent shielding protection and clear etched contours for the non-target areas of the processed workpiece while withstanding the impact of high-energy laser beams.

Core advantages and characteristics

Designed specifically for absorbing or reflecting laser energy of specific wavelengths (such as CO2, Fiber, UV, etc.), it effectively resists burning, carbonization or melting.

Maintain structural stability under laser irradiation to prevent the generation of smoke, residual glue or damage to the optical components of the laser equipment.

Ensure that the laser energy precisely acts on the target etching area to avoid causing thermal damage or accidental marking to the surrounding areas.

Provide clear and sharp etched edges. The tape itself can form clean and neat cutting lines under the action of laser, thus achieving precise transfer of fine patterns and text.

It is an ideal choice for applications such as micro-engraving, serial number marking, QR code generation, and precise pattern etching.

The adhesive formula has been optimized to provide strong and removable adhesion (usually medium adhesion), ensuring no displacement or edge lifting during processing.

Residue-free removal: After processing, the tape can be easily and cleanlessly peeled off without leaving any residue, protecting expensive metal, plastic, glass, coated surfaces and other substrates from scratches, contamination or laser scattering damage.

Simplify the masking process: Compared with traditional liquid coating or manual masking, the application is faster and more uniform.

Reduce post-processing: The step of cleaning the protective coating is omitted, significantly shortening the production cycle and reducing labor costs.

Improving the yield rate: Reliable protection reduces the scrap rate caused by the failure of shielding.

Applicable to a wide range of processed materials, including but not limited to:

Metals: Stainless steel, aluminium, copper, titanium and their alloys.

Plastics: ABS, PC, PMMA (acrylic), PET, engineering plastics, etc.

Coating surfaces: spray-painted parts, anodized aluminum, electroplated parts.

Glass, ceramics, composite materials, etc.

Multiple thicknesses are available (commonly 50μm - 120μm) to meet the requirements of different laser powers and etching depths.

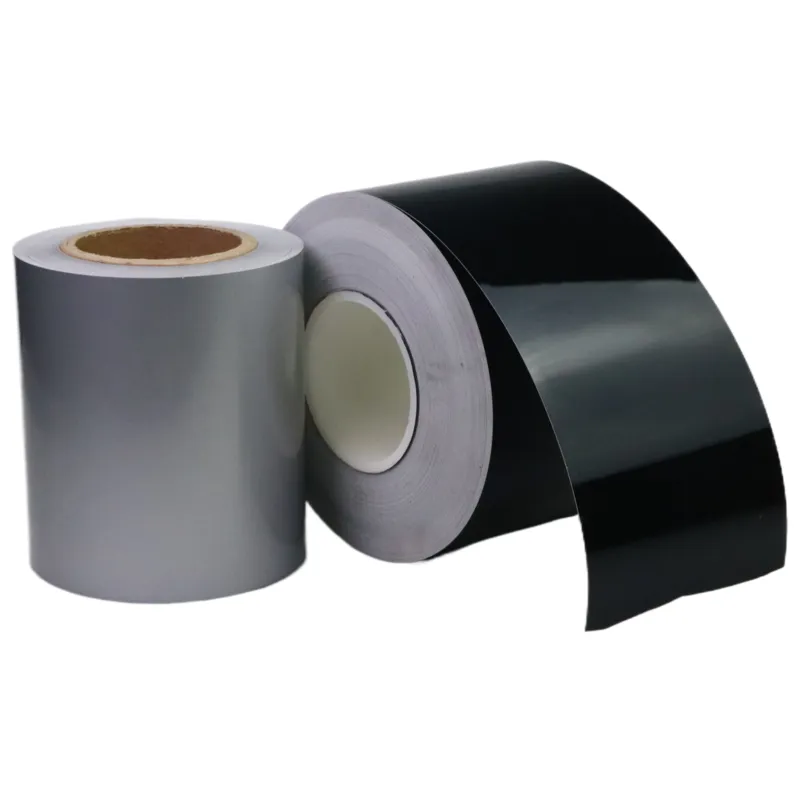

Multiple colors are available (common beige, white, transparent, black, etc.), providing good processing visibility or specific wavelength absorption characteristics.

We offer rolls of different widths to suit both automated mounting and manual operation.

Other types of laser etching tapes

Typical application scenarios

Laser marking/etching protection for precision parts identification: serial numbers, barcodes, QR codes, logos, and production batch numbers.

Decorative etching: Fine patterns and text engraving protection on metal business cards, gifts, trophies, and instrument panels.

Electronics industry: Marking protection for PCB boards (non-soldering areas) and electronic component casings.

Medical devices: Permanent marking etching protection on surgical instruments and implants.

Tools and molds: Model and specification marks on cutting tools and molds.

Automotive parts: Marking and decorative etching on engine components, sensors, and decorative parts.

Sign production: Fine graphic etching of metal and acrylic signs.

Anti-counterfeiting mark: It requires the production of anti-counterfeiting features through high-precision laser etching.

Reasons for choosing Seiko laser etching protective Tape

Guarantee quality: Ensure that the laser-etched patterns are clear and precise, and protect the workpiece surface from being flawless.

Improve efficiency: Simplify processes, reduce waste, and accelerate production.

Reduce costs: Save masking time, cleaning costs and material waste.

Reliable process: Specifically designed for harsh laser processing environments, it features stable and reliable performance.

Seiko Laser Etching Protective Tape - Your reliable guardian of high-precision laser etching technology!

Contact us immediately to obtain samples or customize the solution that best suits your laser parameters and processing requirements!

Instructions for Use (Can be added as needed

Ensure that the surface to be coated is clean, dry and free of oil stains.

Apply the tape evenly according to the shape of the workpiece to avoid bubbles and wrinkles.

It is recommended to conduct small-scale parameter tests to optimize Settings such as laser power, speed, and frequency, and achieve the best etching and protection effects.

After processing, it is recommended to carefully peel off the tape along the edge.

Customized tips

If you have specific laser wavelengths (such as 1064nm, 10.6μm, 355nm, etc.), power ranges, substrate types or special requirements (such as ultra-thin, high-temperature resistance, specific peel strength), we can provide customized products.

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(1)

This Black Silver Laser Etched Label Tape is absolutely fantastic! The etched letters are super clear and crisp, and that black-silver combo looks so sleek and premium. Stuck it on my equipment, and not only is it super easy to read, but it’s held up perfectly—no peeling or fading at all after weeks of use. Totally exceeded my expectations, worth every penny!