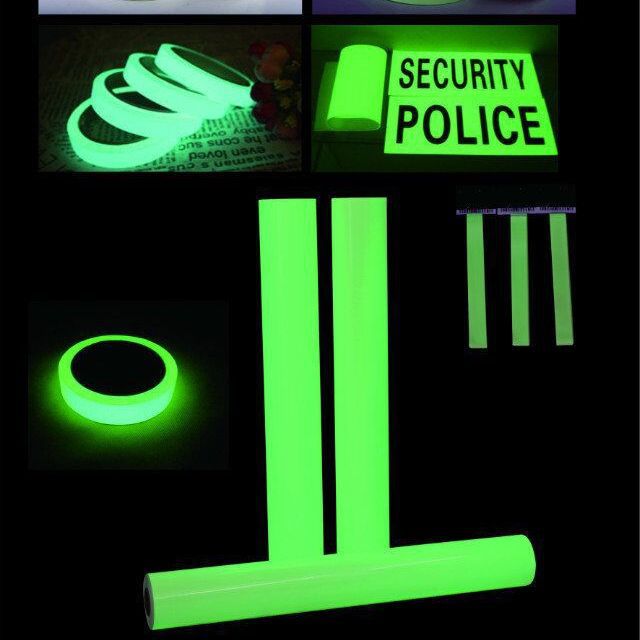

Polyester luminous film tape is a functional tape made of high-quality polyester film (PET) as the base material, coated with a special long afterglow light-accumulating luminous material layer, and combined with high-performance pressure-sensitive adhesive. It can continuously emit clear and bright visible light (usually yellowish green) in a dark environment after absorbing natural light or artificial light sources. It does not require power supply, is safe and environmentally friendly, and provides an ideal solution for various applications that need low-light or dark environment warnings, signs, and decorations.

Product Review:Product Name

High-performance PEt-based luminous warning tape

Luminous Film Core highlights

A long-lasting self-luminous warning sign solution in the dark, combining the excellent performance and strong adhesion of PET substrate.

Product Overview

Polyester luminous film tape is a functional tape made of high-quality polyester film (PET) as the base material, coated with a special long afterglow light-accumulating luminous material layer, and combined with high-performance pressure-sensitive adhesive. It can continuously emit clear and bright visible light (usually yellowish green) in a dark environment after absorbing natural light or artificial light sources. It does not require power supply, is safe and environmentally friendly, and provides an ideal solution for various applications that need low-light or dark environment warnings, signs, and decorations.

Luminous Film Core Features Advantages

High brightness & long afterglow: Utilizing high-efficiency rare earth or alkaline earth aluminate luminescent materials, it features fast light absorption, high initial brightness, and long afterglow duration (typically capable of emitting light for several hours or even longer).

Self-luminous & zero energy consumption: No need to connect to power supply. It can automatically emit light in the dark by absorbing ambient light, which is energy-saving, environmentally friendly and safe to use.

Clearly visible: Provides striking visual indication in low visibility environments such as darkness, smoke or power outages.

High strength & Tear resistance: PET material features excellent mechanical strength, tensile strength and tear resistance, is not easily damaged and is durable.

Strong weather resistance: Excellent temperature resistance (typically -20℃ to 70℃ or higher), UV resistance, moisture resistance, and anti-aging properties, suitable for use in various indoor and outdoor environments.

Dimensional stability: It is not prone to shrinkage or deformation, ensuring that the marking remains clear and accurate for a long time.

Smooth and flat surface: Easy to print, write or stick other labels.

Strong adhesion: High-quality pressure-sensitive adhesives (such as acrylic adhesives) are selected to provide firm initial adhesion and long-lasting bonding force to various common surfaces (such as metal, plastic, glass, wood, walls, etc.).

Strong cohesion: The adhesive layer has good cohesion and is less likely to leave residue when removed (depending on the specific surface and type of adhesive).

Convenient application: Tear and stick immediately, simple and easy to operate.

It contains no radioactive substances and is harmless to the human body and the environment (in compliance with environmental protection directives such as RoHS).

Phosphorus-free and heavy metal-free (specific details depend on the formula).

Luminous film adhesive material products

Luminous Film Typical Application Scenarios

Emergency exit route signs, safety passage guidance, and location markings for fire-fighting equipment (fire extinguishers, fire hydrants).

Anti-slip warnings at the edges of stairs, steps, slopes, and areas with height differences.

Warnings for dangerous parts of machinery and equipment (such as protrusions and near moving parts).

Position markings for distribution boxes, electrical control cabinets, and valve switches.

Anti-collision signs for the edges and columns of warehouse shelves.

Escape direction indicator arrows and evacuation routes within buildings (shopping malls, hotels, office buildings, cinemas, hospitals, schools, underground Spaces).

Emergency exit and route markings for ships, aircraft and other means of transportation.

Personalized DIY decoration (room, party, and festival atmosphere creation).

Luminous artworks and sign production.

Embellishments with toys, models and clothing accessories.

Temporary or permanent signs in environments with no or weak light such as mines, tunnels, and underground projects.

Nighttime positioning of camping equipment and outdoor gear (backpacks, tent zippers).

Low-light indication on the instrument panel and switch panel.

Optional specifications and parameters (Common range)

Width: Commonly available in 12mm, 18mm, 24mm, 36mm, 48mm, 50mm, 72mm, 100mm, etc. Customization is available.

Length: Standard rolls such as 10m, 20m, 33m, 50m, 100m, etc. Customization is available.

Thickness: approximately 0.08mm - 0.15mm (base material + coating + adhesive layer).

Color: The common luminous color is yellowish green (the most sensitive to the human eye, with the longest afterglow), and there are also options such as blue-green, sky blue, and purple.

Afterglow time: Depending on the material grade, the brightness can reach 50-200 mcd/m² or higher within 10 minutes, and the afterglow can last for 8-12 hours or more (attenuating to a level visible to the human eye).

Adhesion: Different adhesion levels (such as low adhesion, medium adhesion, and high adhesion) are provided based on different adhesive types and substrates.

Precautions for Use

Fully "charge" : Before use, ensure that the tape is exposed to a strong enough light source (sunlight or artificial light) for a period of time (usually a few minutes to half an hour) to reach the optimal initial luminance.

Surface cleaning: Before pasting, ensure that the surface to be pasted is dry, clean, free of oil stains and dust to guarantee the best bonding effect and durability.

Ambient light: The stronger the ambient light, the more energy is absorbed, the higher the luminous brightness, and the longer the afterglow time. Long-term exposure to a completely dark environment will affect its luminescent performance (regular "charging" is required).

Temperature influence: Extreme high temperatures may affect the performance of adhesives. Low temperatures may cause the tape to harden and its stickiness to temporarily decrease.

Chemical resistance: Avoid contact with strong solvents, acids, alkalis and other chemical substances, which may damage the surface or affect adhesion.

Summary

PET luminous film tape integrates luminous warning, durability, strong adhesion, safety and environmental protection. It is an ideal choice for enhancing safety, convenience and visibility in low-light environments. Whether for industrial safety, emergency evacuation, facility management or creative design, it can provide reliable, long-lasting and energy-free lighting solutions, bringing peace of mind and guidance to the dark.

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(2)

Ownlikes Polyester Luminous Film Tape Material sticks well and the glow lasts through the night. Practical and reliable for daily use.

I gave the Polyester Luminous Film Tape a try, and it works really well. It glows clearly after charging under light, and the tape sticks firmly. Super useful for marking spots around the house or workshop in the dark.