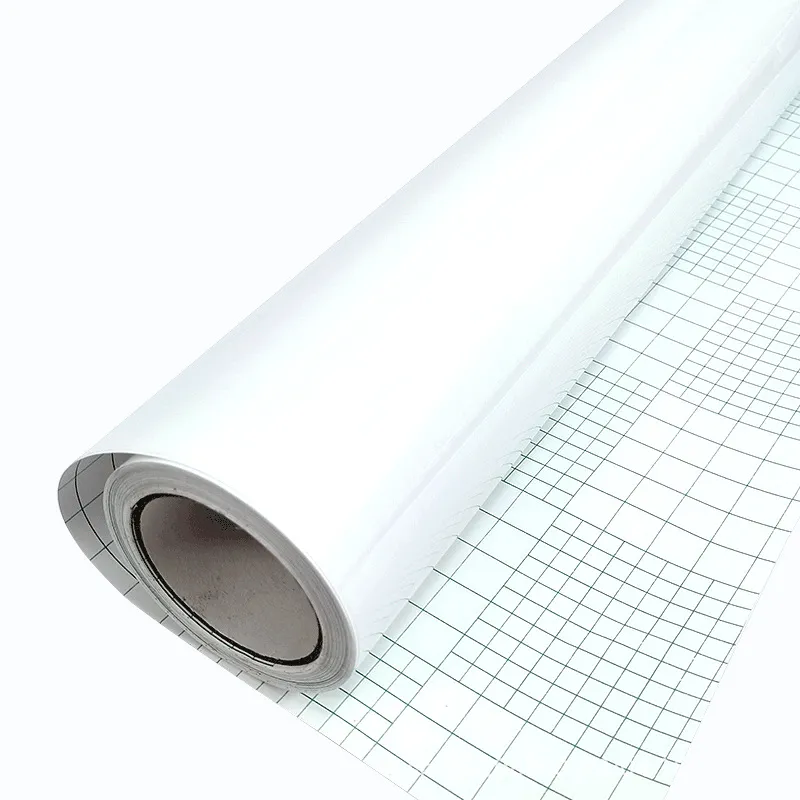

Vinyl film for lamination is made of high-quality transparent vinyl film, with a high-gloss surface treatment. Combined with professional-grade pressure-sensitive lamination and coating technology, it is specially designed to protect outdoor/indoor printed materials, enhance visual effects and significantly extend service life.

Product Review:Product Name: High-Transparency Weather-resistant Vinyl Film for Lamination

Clear Transparent Glass Vinyl Film for Lamination Core Description:

Provide excellent protection and a long-lasting bright optical-grade transparent protective layer for your graphic and text logos. Vinyl film for lamination is made of high-quality transparent vinyl film, with a high-gloss surface treatment. Combined with professional-grade pressure-sensitive lamination and coating technology, it is specially designed to protect outdoor/indoor printed materials, enhance visual effects and significantly extend service life.

Vinyl Film for Lamination Category

Vinyl Film for Lamination Core Features Advantages

High transparency: It offers a crystal-clear visual effect, perfectly showcasing the colors and details of the underlying printed patterns without any blurring or fogging.

Mirror-like luster: The surface has undergone special treatment, presenting a bright and sharp high-gloss effect, which greatly enhances the visual impact and professional texture of the printed matter, making the colors more vivid and full.

Excellent weather resistance: The transparent vinyl (PVC) film stabilized with high-grade plasticizers can effectively resist ultraviolet radiation (UV resistance), rain, moisture, temperature changes and erosion by general chemicals, preventing fading, cracking, shrinkage or curling.

High strength and toughness: It has excellent tear resistance, puncture resistance and wear resistance, providing a reliable physical protective layer for the adherend.

"Tear and stick immediately: Back-coated with high-performance pressure-sensitive adhesive, it has strong adhesion and excellent initial adhesion, making it easy to peel off the backing paper for quick and precise bonding."

Long-lasting adhesion: Specifically designed for long-term applications, it offers excellent final bonding strength, ensuring a firm bond on various flat or slightly curved substrate surfaces (such as acrylic, glass, metal, spray-painted images, etc.) without lifting edges or falling off.

Removal clean (optional) : Depending on the specific formula, some models can achieve no residue or low residue during removal (please confirm the specific product specifications).

Comprehensive protection: As a laminating layer, it can effectively block dust, stains, fingerprints, scratches and mild chemical contact (such as oil stains, cleaning agents), keeping printed materials looking as good as new for a long time.

Enhance durability: Significantly improve the scratch resistance and overall structural strength of the adhered materials (especially outdoor advertisements, car body stickers, window stickers, etc.).

Waterproof and moisture-proof: It provides a waterproof barrier for printed images, especially suitable for outdoor or humid environments.

Vinyl Film for Lamination Typical Application Scenarios

Outdoor advertising signs: body stickers, bus advertisements, outdoor light boxes, billboards, display boards, and film protection for banners and curtains.

Indoor display and decoration: window stickers, glass door stickers, floor stickers, wall decoration stickers, display cabinet films, protective lamination for large-format posters.

Industrial and product labeling: Durable equipment labels, instrument panel coverings, product casing protective films.

Photo and Artwork protection: Provide gloss protection and enhancement effects for large-format photos, posters, and printed artworks.

Temporary or permanent signs: All kinds of signs and stickers that require high transparency and excellent weather resistance.

Vinyl Film for Lamination Reasons for Selection

Enhance value: Significantly improve the visual grade and service life of printed materials in an economical and efficient way.

Peace of Mind Protection: Provide a strong environmental protection barrier for your investment (printed materials/logos).

Easy operation: The self-adhesive design simplifies the installation process, saving time and labor costs.

Professional presentation: The high-gloss and transparent effect brings a professional, high-end and eye-catching visual experience.

It is suitable for most solvent-based, water-based and UV inkjet printed products. It is recommended to ensure that the surface to be adhered is clean, dry and free of grease before bonding. Select the appropriate model (such as thickness, adhesive type) based on the specific application environment (such as extreme outdoor, curved surface bonding).

Vinyl Film for Lamination Instructions for Use (Optional)

Make sure the surface to be pasted is clean, dry, dust-free and oil-free.

Measure and cut the required size of the film (it is recommended to be slightly larger than the picture).

Start slowly peel off the backing paper from one corner, and at the same time use a scraper (or similar tool) to evenly and smoothly apply the film onto the picture to drive away the air bubbles.

Trim the excess parts at the edges.

(Optional) After lamination, apply a certain pressure or leave it for a period of time to achieve the best bonding strength.

Specification Notes: Multiple thickness (such as 2mil, 3mil, 5mil, etc.) and width options are provided to meet different application requirements. Comply with relevant environmental protection and safety standards (such as RoHS).

Vinyl Film for Lamination Description Emphasizes

Core materials: Transparent vinyl, self-adhesive, laminating function.

Key visual features: high gloss, high transparency.

Core performance advantages: Weather resistance (UV resistance, water resistance), protection (scratch resistance, stain resistance), strong adhesion, easy operation.

Value proposition: Enhance visual effects, extend lifespan, and protect investment.

Clear application scenarios: Let customers know where it can be used.

Professionalism: Industry terms are used, but the expression is clear and easy to understand.

You can make minor adjustments based on the specific brand of the product, the target customer group (professional printing factories vs. end users), or special selling points (such as removable, special environmental protection certifications).

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(1)

The Clear Transparent Glass Vinyl Film for Lamination is top-notch! It’s crystal clear, providing excellent protection without changing the look of my prints. The glossy finish adds a sleek, polished feel to everything