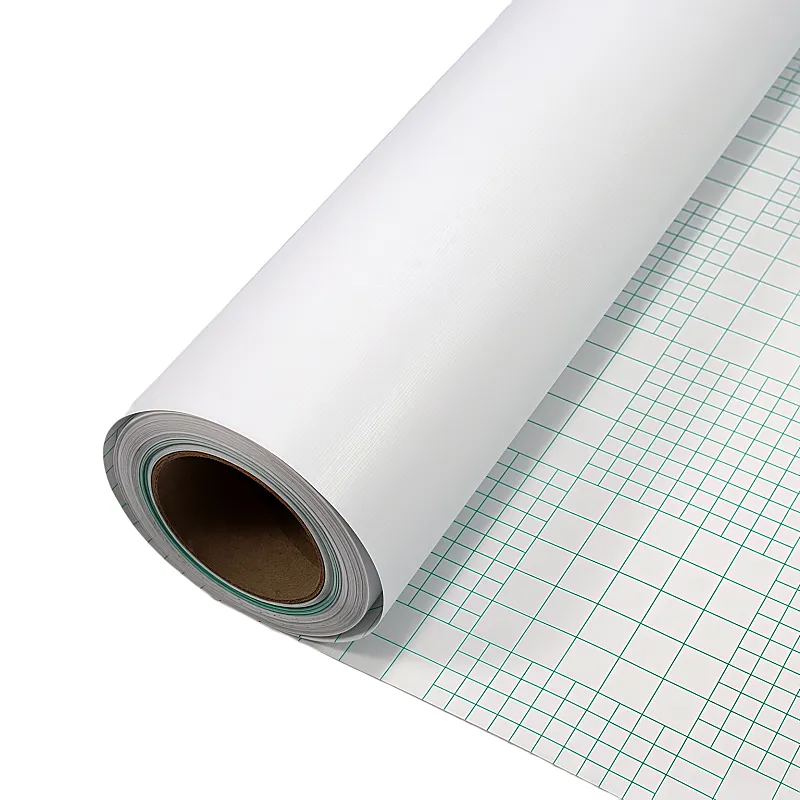

Cross Texture Vinyl Film for Lamination is a high-end laminating material that combines outstanding aesthetic effects, strong durability and convenient construction features. Designed specifically for signage, advertising, decoration and packaging applications that pursue unique texture and long-term protection.

Product Review:Product Description: Cross Texture Vinyl Film for Lamination

Professional-grade surface texture and long-lasting protection are perfectly presented

Cross Texture Vinyl Film for Lamination is a high-end laminating material that combines outstanding aesthetic effects, strong durability and convenient construction features. Designed specifically for signage, advertising, decoration and packaging applications that pursue unique texture and long-term protection.

Vinyl Film for Lamination Category

Vinyl Film for Lamination Core Features Advantages

The surface presents a fine and three-dimensional cross-woven texture, endowing the image or background color with a high-end fabric-like touch and visual layering.

It effectively enhances the texture and professional image of design works, and is more artistically expressive than ordinary smooth or matte facial masks.

It can effectively hide minor flaws (such as bubbles and dust particles) that may occur during the substrate or the bonding process.

Made of high-quality, flexible PVC vinyl film, it features excellent tear resistance, scratch resistance and wear resistance.

It provides good dimensional stability, is not prone to shrinkage or deformation, and ensures a smooth and beautiful appearance for long-term use.

Excellent UV resistance performance effectively delays image fading and extends outdoor service life.

Apply industrial-grade permanent or removable pressure-sensitive adhesive (depending on the specific model) to provide strong and long-lasting adhesive force.

It is suitable for various smooth and clean surfaces (such as glass, metal, plastic, acrylic, spray-painted coatings, etc.).

The carefully designed adhesive layer ensures easy operation during pasting (with moderate initial adhesion), good air release, and is less likely to produce air bubbles, ultimately achieving a firm bond (with strong final adhesion). The removable version is less likely to leave residual glue after removal.

As a surface coating layer, it provides comprehensive physical protection for the printed materials below (such as posters, photos, labels, stickers, menus, engineering drawings) or the substrate.

Effectively resist daily scratches, stains, fingerprints, water splashes and mild chemical erosion, keeping the picture clean and as good as new.

Enhance the overall thickness and stiffness of the substrate material to improve the hand feel and durability.

The film surface has good flexibility and is easy to cut, die-cut and edge wrap.

The construction is relatively simple, and it has certain stretchability and plasticity. It is especially suitable for scenarios that require covering curved surfaces or corners (which have certain requirements for construction skills).

Compatible with common inkjet printing (specific model matching needs to be confirmed) and lamination processes.

Vinyl Film for Lamination Typical Application Scenarios

High-end indoor and outdoor signage: shop signs, light box panels, display boards, notice boards, directional signs (especially suitable for occasions that need to show texture or hide flaws).

Vehicle decoration: Body advertising stickers, window stickers (for some models), motorcycle/electric vehicle decals (with unique textures provided).

Commercial space decoration: Wall decoration film, glass partition decoration, counter finish, elevator car decoration.

Advertising display: High-end self-adhesive poster lamination, display stand images, pull-up banner images, X-stand images.

Durable labels and stickers: Equipment labels, asset labels, product labels, and promotional stickers that require long-term durability and quality.

Menus and catalogues: The covers of restaurant menus, wine lists, and product catalogues are laminated to enhance texture and durability.

Protective lamination: Provides a textured protective layer for important documents, maps, engineering drawings, photos, etc.

Vinyl Film for Lamination Reasons for Selection

Enhance the sense of value: The unique cross-shaped fabric texture significantly elevates the visual and tactile grade of the product.

Durable: Excellent weather resistance, scratch resistance and tear resistance ensure long-term usage effect.

Comprehensive protection: As a protective layer, it effectively extends the service life of the internal printed matter or substrate.

Reliable adhesion: High-performance adhesive back provides a strong and long-lasting bonding effect.

Wide application: Suitable for various fields ranging from professional advertising signs to creative decoration.

Provide your high-quality projects with ideal surface solutions that are both aesthetically pleasing, protective and durable!

Vinyl Film for Lamination Usage Tips

Before pasting, ensure that the construction surface is absolutely clean, dry and free of grease. This is the key to achieving the best bonding effect.

It is recommended to use a scraper or a scraper card during construction to assist in venting and compaction to achieve a smooth and bubble-free effect.

For long-term outdoor use, choose models that are clearly marked as having high UV resistance.

Choose the type of permanent adhesive or removable adhesive based on the final use (whether it needs to be removed or not).

You can further supplement the details based on parameters such as the brand, thickness, type of glue (permanent/removable), and UV resistance level of the specific product.

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(1)

The Cross Texture Vinyl Film for Lamination looks great! The texture adds a nice touch, and the finish feels smooth and strong. It sticks well and gives projects a clean, stylish look