Beverage and cold chain food adhesive label materials

adhesive labels are widely used in daily life, such as beverage and alcoholic beverages, daily chemical and washing products, pharmaceuticals, cold chain food, and supermarket logistics. Here, we will focus on the common beverage and low-temperature supermarket labels in daily life

1. Beverage label

Beverage label packaging is increasingly pursuing personalization, and labels usually require excellent printing effects, short-term reapplication on PET material without residue, short-term water resistance without whitening, super transparency, moisture resistance, safety and environmental protection functions

From the perspective of safety and environmental protection, water-based adhesives can meet such applications. However, in terms of the characteristics of water-based adhesives, water whiteness and anti residue adhesive performance are the difficulties in material design. Zhejiang Guanhao designed the F4300 product from the formula and adopted a unique production process, which has excellent anti residue adhesive performance, low odor, and water whitening resistance in terms of viscosity and PET material

(Water Whiteness: Water based pressure-sensitive adhesives contain hydrophilic substances. After water enters the adhesive layer, light transmits and forms a refraction phenomenon. From a macroscopic perspective, the label will turn white after being soaked in water for a certain period of time. Due to the humid filling environment of beverages, there may be some overflow situations. Therefore, in order to ensure the appearance of the product, the label adhesive needs to have a certain degree of water whitening resistance.)

Testing method:

1. After tearing off the bottom paper of the label, soak the adhesive surface directly in room temperature water

2. After leaving it for a period of time, observe the whitening of the adhesive surface

It can be seen that ordinary glue has a serious whitening phenomenon after being soaked in water. Ordinary water-resistant glue has a certain effect, and the best material is specially treated for this problem

Poor UV curing leads to ink loss

Ink shedding is also closely related to the curing effect of UV ink. If the power of the UV lamp is insufficient or the printing speed is too fast, a "false dry" phenomenon may occur, which can easily lead to ink loss. The so-called 'false drying' refers to the situation where the surface of the ink has already dried/solidified, while the interior has not completely dried/solidified. It should be noted that ink drop caused by this phenomenon often occurs in printing large areas of solid patterns. This is because the solid pattern requires a large amount of ink, and the interior of the ink layer is not easily completely cured. In addition, sometimes only one color of ink printed at the same time has noticeable ink loss, with the most common being severe ink loss in black ink. This is because UV light is difficult to penetrate the black ink layer, and in most cases, black ink is arranged in the last color group for printing, with the shortest total curing time and difficult to completely cure.

When encountering such problems, you can first check whether the UV lamp has exceeded its rated service life. If it has, the lamp needs to be replaced. If the UV lamp is in normal service life, it should be due to insufficient power of the UV lamp. You can increase the power of the UV lamp appropriately or reduce the printing speed.

However, for thin film adhesive materials, this treatment may lead to new problems - when the printing speed is too low or the UV lamp power is too high, it is likely to cause deformation of the thin film adhesive materials due to significant heat exposure per unit time. When encountering such problems, it is advisable to reduce the ink supply appropriately and increase the printing speed or UV lamp power moderately to ensure thorough ink curing. If reducing the ink supply leads to virtual printing on the spot, it is necessary to use a two-stage printing method to solve the problem.

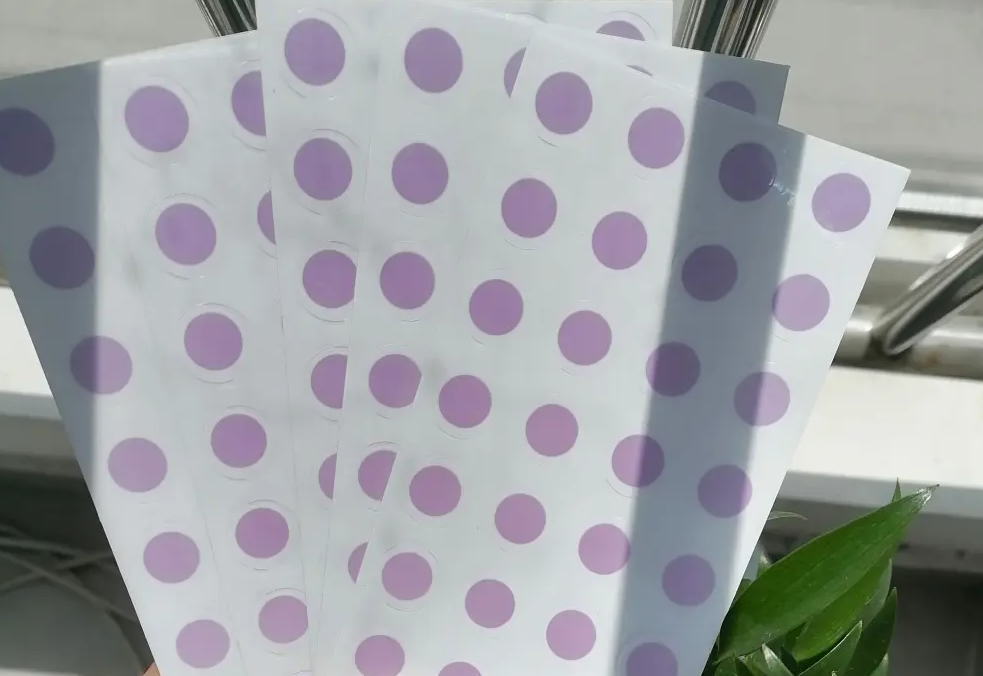

UV color changing label

The initial color of the UV irradiation color changing indicator label sticker is yellow before being irradiated. After being irradiated with UV light at around 365nm, the color begins to change when the irradiation dose reaches about 250-400mJ/cm2. The larger the UV irradiation dose, the darker the color and gradually approaches deep purple. The label color after UV irradiation can remain stable under normal conditions for a long time.

The UV irradiation color changing indicator label sticker is designed for detecting and monitoring UV irradiation processing management and process quality control, such as UV curing and UV sterilization process quality control, providing additional visual inspection methods for quality detection and monitoring indicators, thereby eliminating uncertainty factors. The depth of color can be used to roughly determine the amount of UV exposure or to determine whether the UV lamp needs to be replaced; By using this UV color changing indicator label, it is possible to reliably visually determine whether the product has undergone UV irradiation, thereby enabling rapid verification of product irradiation quality and effectively reducing costs. This self-adhesive label has strong adhesion and can firmly adhere to the surface of most items, but it is still recommended that users conduct adhesive performance testing before use to ensure that the adhesive position is appropriate. When using this product for applications in unconventional environments, users should conduct relevant performance tests in advance.

Laser film adhesive label

In the labeling industry, laser film adhesive labels have gradually become the new favorite of the market due to their unique visual effects and wide application fields. This type of label uses a special laser film as the surface material, and through laser engraving technology, various exquisite patterns and text are formed on the surface of the film, presenting a unique laser effect, making the label more eye-catching and attractive.

Laser film adhesive labels not only have a beautiful appearance, but also excellent performance. Its surface material has good weather resistance, water resistance, and chemical stability, and can maintain clear patterns and text in various environments. At the same time, the adhesive part of the label has been specially designed to have excellent adhesion and peel resistance, ensuring that the label can be firmly attached to the surface of the product and is not easily peeled off.

This type of label is widely used in various industries and fields such as food, beverage, medicine, daily chemical, electronics, etc. In the food industry, laser film adhesive labels can be used to label information such as production date and shelf life on packaging; In the pharmaceutical industry, it can be used for anti-counterfeiting labeling on drug packaging; In the electronics industry, it can be used for labeling information such as serial numbers and barcodes on products.

Fragile stickers

Fragile paper adhesive labels are an important type of adhesive label, and their fabric fracture strength is much lower than the adhesive bonding ability. They have the characteristics of being unable to be completely peeled off and cannot be reused after being pasted. Fragile paper adhesive surface materials are processed through printing, die-cutting and other processes to produce fragile labels or fragile stickers, also known as product fragile warranty stickers. It is mainly used for unconventional product identification methods that are difficult to accurately guarantee with formal warranty methods.

Fragile paper adhesive surface material is suitable for printing and processing in the form of roll barrel paper on label machines. Due to the low strength of the surface material, fragile paper only needs to be printed and die cut without waste disposal; The finished product label is only sliced and not rewound. So fragile paper adhesive labels cannot be automatically labeled and are all manually labeled.

Fragile paper: transparent fragile, laser fragile, white fragile

Widely used in the quality assurance of high-end products such as mobile phones, telephones, computer accessories, automotive appliances, alcohol, drugs, food, cosmetics, and performance tickets, it can also be applied to anti-theft and tamper proof products in shopping malls. The characteristics of the guaranteed products are high price, large warranty responsibility, and high requirements for the accuracy of warranty dates. Therefore, the quality of fragile stickers is directly related to the quality of product after-sales service and the economic interests of merchants. The use of this anti-counterfeiting material can effectively avoid various losses and disputes.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.