Golden onion flash cold laminating film is a multifunctional surface coating material specially designed for high-end packaging, labels, decoration and creative design. Its unique golden scallion glittering effect, combined with the cold lamination process, endows the product with a luxurious texture and visual impact. At the same time, it features excellent durability and convenient processing performance, and is widely used in printing and packaging, advertising production, gift decoration, brand identification and other fields.

Product Review:Matte cold laminating film - professional-level surface protection and texture upgrade solution

Product Overview

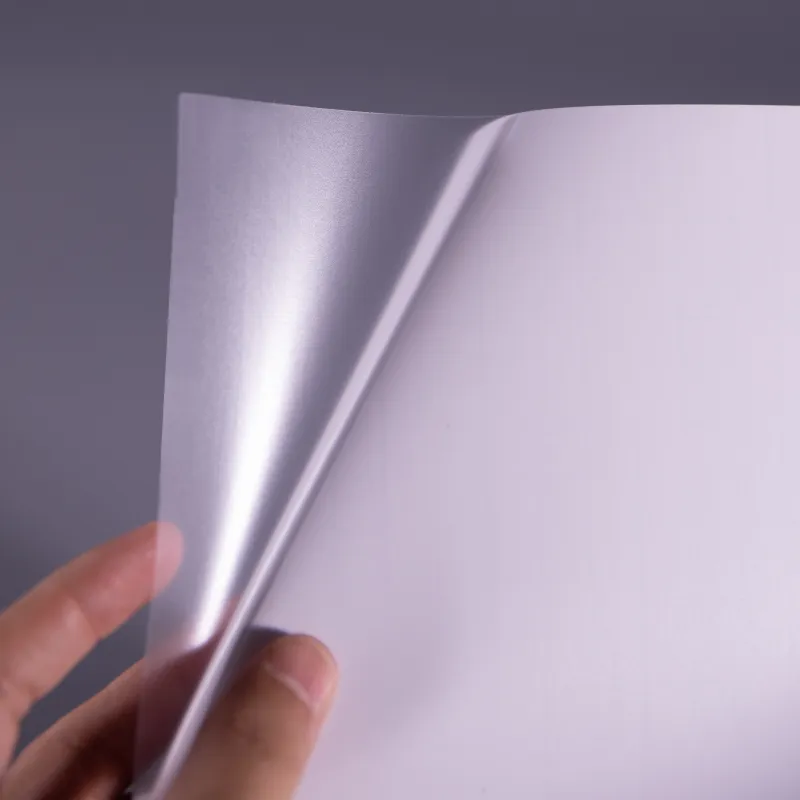

Matte cold laminating film is a functional laminating material specially designed for high-end printed matter, labels, signs and packaging design. Adopting advanced cold lamination technology, it can be easily bonded without high-temperature heating, endowing printed materials with a matte and frosted texture. At the same time, it provides comprehensive protection such as scratch resistance, anti-fingerprint, and weather resistance, making it an ideal choice for enhancing the grade and practicality of products.

Product categories of Laminating Film

Core characteristics

The surface is finely matte treated to eliminate reflective interference, presenting a soft visual effect with a smooth touch. It is suitable for scenarios such as high-end brand packaging, art posters, and luxury stickers.

Effectively hide minor flaws in the substrate and enhance the overall texture of the printed matter.

No heating equipment is required. It can be quickly laminated at room temperature either manually or with a laminating machine, saving energy and time costs and avoiding damage to sensitive materials caused by high temperatures.

The self-adhesive back adhesive design allows for precise adhesion by simply tearing off the backing paper, reducing air bubbles and wrinkles.

Scratch-resistant, stain-proof, water-resistant and moisture-proof, suitable for both indoor and outdoor environments, extending the service life of printed materials.

Anti-ultraviolet formula, delays fading, ensuring the color remains bright and new for a long time.

It is compatible with various substrates such as coated paper, synthetic paper, PET, and PVC, and is suitable for processes like inkjet printing, laser printing, and screen printing.

It supports post-processing such as die-cutting, hot stamping and local UV coating to meet personalized demands.

Application scenarios

Commercial printing: product labels, tags, promotional stickers, outdoor advertising stickers.

Packaging design: cosmetic boxes, electronic product packaging, food and beverage bottle bodies (in compliance with food contact safety standards).

Creative design: photo album lamination, notebook decoration, DIY handicrafts.

Industrial identification: equipment nameplates, barcode labels, warehouse shelf stickers.

Technical parameters (Example)

Thickness: 80μm/100μm (optional)

Viscosity strength: ≥ 3.5N /25mm

Temperature resistance range: -20℃ to 80℃

Base material width: Customizable (Standard 30cm/50cm/1m roll)

Usage Tips

Before bonding, ensure that the surface of the base material is clean, dry, free of grease and dust.

When adhering, press slowly from one end to avoid air residue.

Store in a cool and dry place, away from direct sunlight.

Packaging and Service

A4 and A3 sizes are supported, and slitting customization is available.

Free sample trials are provided, and a professional technical team supports customized solutions.

Enhance brand quality, starting with a film!

Matte cold-laminated self-adhesive film - Let your design stand out in a low-key way.

(Note: Further adjustments and optimizations can be made based on actual product parameters, certification standards or customer requirements.)"

Cold Laminating Film Common Question Treatment

1. Insufficient film pressure -- adjust the pressure of the cold mounting machine;

2. The two ends of the cold laminating machine are not smooth -- adjust the adjusting screws of the distance between the cold laminating machines to achieve equal distance;

3. Over-photo paper - the surface of the photo paper is uneven, generally about 25 degrees, placed 2-3 hours will automatically disappear, the higher the temperature will disappear faster;

4. Over PP glue --A. hand touch PP glue screen if there is no "rough" feeling, then according to the above method; B. There is a "rough" feeling that requires more PP backing glue;

5. Glue viscosity is not good at low temperature --A. Improve the use of ambient temperature. B. Replace the cold mounting film

1. The glue is not sticky enough --A. Increase the ambient temperature,B. Replace the cold mounting film;

2. Thin glue - the general distance is not long, the probability of greater before and after shutdown, generally pull off a few meters;

3.PP adhesive surface hand touch "rough" feeling --A. Replace PP adhesive,B. Or use studio film over the picture;

4. There is dust in the air --A. Purify the operating environment,B. Close the blower or air inlet source;

5. Water droplets (such as saliva) inadvertently splash on the surface of the spray painting --A. Pay attention when operating, especially when speaking, do not face the picture,B. Air temperature in dry environment, such as air conditioning, hot fan or ventilation.

1. The glue does not "mature" -- change the cold mounting film

1. The glue is not "matured" thoroughly -- open the cold mounting film

Pack and place in the air for 2-5 days to allow the glue to fully "mature" under natural conditions;

2. The picture is not sufficiently dry, especially in winter, because there are antifreeze components in the winter ink, which is not easy to volatilize completely.- Let the picture be fully dry, the general winter time is twice as long as summer and autumn above, and then over the painting (must pay attention to dust);

3. Large area single color such as: all black/all red, etc. --A. Light color,B. Replace ink,C. Fully dry the picture (completely dry),D. heat the picture,E. replace the more viscous cold mounting film, the thinner the better.

4. The ambient temperature is low, so that the cold laminating film surface is too hard -- improve the ambient temperature when using;

5. Cold mounting film is too thick -- replace it with a thin cold mounting film;

6. Roll up immediately after painting, the glue and the picture are not fully integrated - after painting, place it flat for more than 45 minutes and then roll it up.

7. Aging glue -- Replace the cold mounting film.

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(1)

Used the Matte Cold Laminating Film for a recent print job — smooth application and no bubbles. The matte finish reduces glare and gives everything a clean, professional look. It’s a solid option for protecting prints without the shine