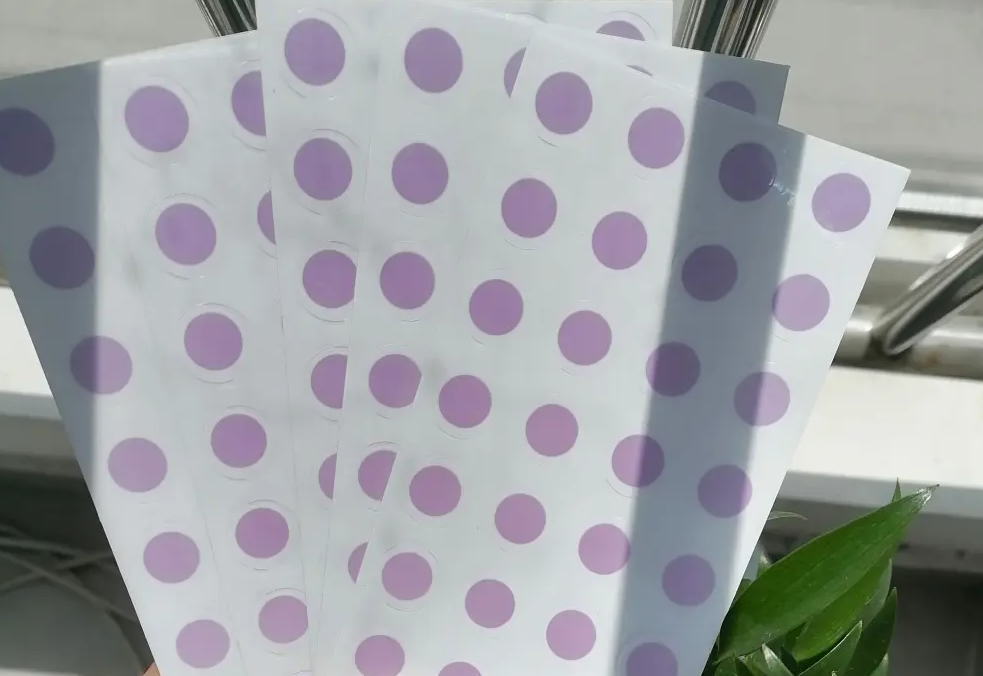

UV color changing label

The initial color of the UV irradiation color changing indicator label sticker is yellow before being irradiated. After being irradiated with UV light at around 365nm, the color begins to change when the irradiation dose reaches about 250-400mJ/cm2. The larger the UV irradiation dose, the darker the color and gradually approaches deep purple. The label color after UV irradiation can remain stable under normal conditions for a long time.

The UV irradiation color changing indicator label sticker is designed for detecting and monitoring UV irradiation processing management and process quality control, such as UV curing and UV sterilization process quality control, providing additional visual inspection methods for quality detection and monitoring indicators, thereby eliminating uncertainty factors. The depth of color can be used to roughly determine the amount of UV exposure or to determine whether the UV lamp needs to be replaced; By using this UV color changing indicator label, it is possible to reliably visually determine whether the product has undergone UV irradiation, thereby enabling rapid verification of product irradiation quality and effectively reducing costs. This self-adhesive label has strong adhesion and can firmly adhere to the surface of most items, but it is still recommended that users conduct adhesive performance testing before use to ensure that the adhesive position is appropriate. When using this product for applications in unconventional environments, users should conduct relevant performance tests in advance.

Laser film adhesive label

In the labeling industry, laser film adhesive labels have gradually become the new favorite of the market due to their unique visual effects and wide application fields. This type of label uses a special laser film as the surface material, and through laser engraving technology, various exquisite patterns and text are formed on the surface of the film, presenting a unique laser effect, making the label more eye-catching and attractive.

Laser film adhesive labels not only have a beautiful appearance, but also excellent performance. Its surface material has good weather resistance, water resistance, and chemical stability, and can maintain clear patterns and text in various environments. At the same time, the adhesive part of the label has been specially designed to have excellent adhesion and peel resistance, ensuring that the label can be firmly attached to the surface of the product and is not easily peeled off.

This type of label is widely used in various industries and fields such as food, beverage, medicine, daily chemical, electronics, etc. In the food industry, laser film adhesive labels can be used to label information such as production date and shelf life on packaging; In the pharmaceutical industry, it can be used for anti-counterfeiting labeling on drug packaging; In the electronics industry, it can be used for labeling information such as serial numbers and barcodes on products.

Fragile stickers

Fragile paper adhesive labels are an important type of adhesive label, and their fabric fracture strength is much lower than the adhesive bonding ability. They have the characteristics of being unable to be completely peeled off and cannot be reused after being pasted. Fragile paper adhesive surface materials are processed through printing, die-cutting and other processes to produce fragile labels or fragile stickers, also known as product fragile warranty stickers. It is mainly used for unconventional product identification methods that are difficult to accurately guarantee with formal warranty methods.

Fragile paper adhesive surface material is suitable for printing and processing in the form of roll barrel paper on label machines. Due to the low strength of the surface material, fragile paper only needs to be printed and die cut without waste disposal; The finished product label is only sliced and not rewound. So fragile paper adhesive labels cannot be automatically labeled and are all manually labeled.

Fragile paper: transparent fragile, laser fragile, white fragile

Widely used in the quality assurance of high-end products such as mobile phones, telephones, computer accessories, automotive appliances, alcohol, drugs, food, cosmetics, and performance tickets, it can also be applied to anti-theft and tamper proof products in shopping malls. The characteristics of the guaranteed products are high price, large warranty responsibility, and high requirements for the accuracy of warranty dates. Therefore, the quality of fragile stickers is directly related to the quality of product after-sales service and the economic interests of merchants. The use of this anti-counterfeiting material can effectively avoid various losses and disputes.

Mirror coated paper adhesive label

Mirror coated paper adhesive labels, as a shining pearl in the label industry, have won wide market favor with their unique elegant luster and excellent practical functions. This type of label uses high-quality mirrored copperplate paper as the surface material, which has undergone special processing to present a glossy effect like a mirror, making the label visually more attractive and instantly enhancing the product's grade and texture.

In addition to its eye-catching appearance, mirror coated paper adhesive labels also have excellent performance. Its surface material has good weather resistance, water resistance, and chemical stability, which can maintain the integrity and clarity of the label in various harsh environments. At the same time, the adhesive part of the label has been carefully designed to have strong adhesion and long-lasting retention, ensuring that the label can be firmly attached to the surface of the product without easily falling off or lifting.

This type of label is widely used in high-end cosmetics, alcohol products, electronic products, and other fields that require showcasing an elegant image and a sense of quality. In the cosmetics industry, mirror coated paper adhesive labels are commonly used on bottle bodies or packaging boxes to highlight the luxurious feel of products; In the liquor industry, it is commonly used for label making, adding a unique shine to the bottle; In the electronics industry, it can be used to label product information, serial numbers, etc., while enhancing the overall image of the product.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.