Belt vulcanization label material

Used for belts, hoses, air springs, and other rubber products. Print real-time variable data on pre printed materials using a heat transfer printer, and then transfer it to rubber materials through heat transfer and pressure transfer. The heat and pressure generated by vulcanization can permanently transfer the identification onto the rubber. It can also be applied after vulcanization, and different colors can further distinguish the type and production line of the product. Provide efficient product management solutions for belt and rubber enterprises

Features and Advantages

There are multiple colors that can be used before and after vulcanization. It can be used for low-temperature printing of EPDM rubber and fluoroprene rubber. Real time variable data can be printed on pre printed materials, and the barcode and visible text recognition rate are high after vulcanization

Material List for Belt Vulcanization Labels

High temperature resistant steel label material

The steel industry identification is specifically used for coating metal label materials on steel formed parts such as plates, coils, wires, and bars. At the same time, excellent coating technology makes barcode printing and printing feasible. Due to the special nature of the industry, label materials must withstand extreme high temperatures, acid and alkali, oil stains, and friction during production and transportation, as well as various impacts such as harsh weather conditions

High temperature resistant steel labels are used in extremely harsh production environments for steel and aluminum materials. Excellent coating technology makes them suitable for heat transfer printing, with an extreme temperature resistance of 1300 ° C; C。 Used for tracing information such as steel grade, production batch, production flow, specifications, weight, etc. throughout the entire heat treatment process

Application

Marking of plates, wires, rods, coils, and pipes

Steel wire, steel coil, and section steel

Aluminum products

Continuous casting production, die-casting molds

High pressure gas cylinder

Inventory management, process management

Features and Advantages

Multiple materials and different thicknesses

Polyacrylic acid adhesive and silicone, halogen-free

Excellent printing and printing effect

Can withstand 1300 ° C; High temperature, high-strength substrate, tear resistant

Super adhesive, resistant to chemicals, moisture, and dirt

Thermal transfer printing coating, compliant with REACH and ROHS standards

Printable ceramic barcode label material

Glass ceramic bathroom label materials can be used for identification and barcode management of ceramics, glass, light bulbs, steel, and wheel products. After permanent curing, the label and printed image can withstand 1300 degrees Celsius; High temperature and excellent friction resistance

Used for belt and ceramic bathroom label materials, it can be used for metal and ceramic product identification and barcode surface, 300° C or above can be permanently cured in 30 minutes, and after curing, it can withstand 1300 degrees Celsius; High temperature, excellent wear resistance, water washing resistance, and scratch resistance

Features and Advantages

There are two types of coatings: transparent and white Easy to print and print

300° C or above, permanently cured for 30 minutes, and can withstand 1300 ° C after curing; C high temperature

Can be used on the surface of ceramics, glass, and light bulbs

Wear resistant and scratch resistant

Can withstand the harsh production environment of the ceramic bathroom and glass industry

Ultra high temperature resistance and good performance

The substrate is made of inorganic materials Waterproof, acid-base, most oil stains, and low-fat solvents

Usage

1. Immerse the label in water and remove the backing paper. The label will curl up in the water, and after a while, the water will penetrate into the label. After 5-10 seconds, the backing paper can be torn off< br /> 2. When applying labels, it is necessary to slowly slide one side of the label onto the object to attach the label. Avoid label wrinkles and air ingress. If the label is wrinkled or air enters, it may be easily peeled off

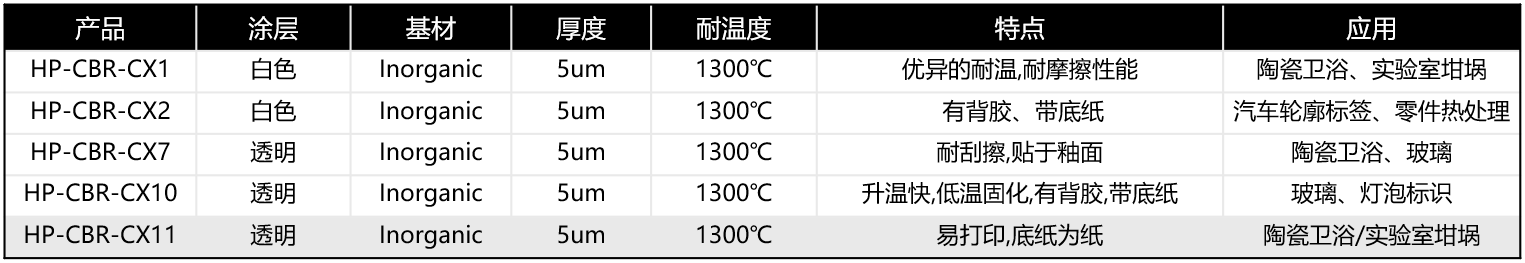

Material List for Printing Ceramic Barcode Labels

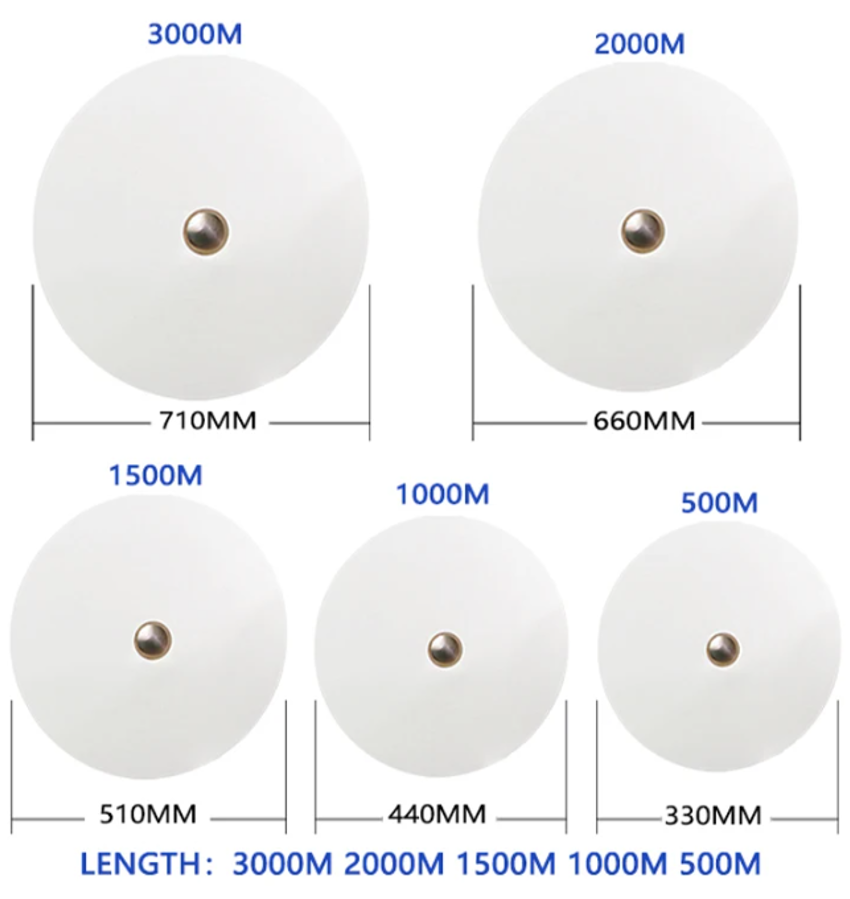

About Material Roll Packaging Information

Material width: 530mm, 1070mm (can be cut into any width size)

Substrate thickness: 25um, 50um, 75um, 100um optional

Release paper: 80g Gracin base, 120g offset paper base

Material Core: Paper Core Wall Thickness 5mm * Inner Diameter 75um

Packaging method:

500M-1000M length: first wrap with wrapping film and foam, then wrap the edge products with corrugated paper, and then fix the material roll with packing rope to the card board

1500M-3000M length: wrap with wrapping film and foam, add a plug to the shaft core, and then fix the wood plate on the side of the material roll with wrapping rope

Material roll diameter: as shown in the figure

Regarding the transportation information of material rolls

20 foot container: internal dimensions 5.69 meters X 2.13 meters X 2.18 meters/gross weight of goods generally 17.5 tons/volume 24-26 cubic meters

Card size: 15mm * 1M * 1.1M * 1.5M

Number of cardboards: Maximum number of rolls 52 rolls 1.07M * 1500M

Applicable Material Rolls: Length 500M, 1000M, 1500M, Cut Material Rolls

40 foot container: internal dimensions of 11.8 meters X 2.13 meters X 2.72 meters/gross weight of goods generally 22 tons/volume of 68 cubic meters

Card size: 15mm * 1M * 1.1M * 1.5M

Number of cardboards: Maximum number of rolls 55 rolls 1.07M * 3000M

Applicable Material Rolls: Length 2000M, 3000M, 5000M

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.