Cold laminated film is made of transparent BOPP by adhesive processing, according to the texture of the film surface can be divided into light film, matte film, frosted film, star phantom film, holographic film and special texture of the protective film, in the production of advertising is a large number of light film, matte film, frosted film. The cold-pressed film is overlaid on the photo printed picture by hand or cold press, to avoid the picture (printing surface) being scratched, contaminated or wet, and to protect the picture.

Product Review:Cold laminated film is made of transparent BOPP by adhesive processing, according to the texture of the film surface can be divided into light film, matte film, frosted film, star phantom film, holographic film and special texture of the protective film, in the production of advertising is a large number of light film, matte film, frosted film. The cold-pressed film is overlaid on the photo printed picture by hand or cold press, to avoid the picture (printing surface) being scratched, contaminated or wet, and to protect the picture.

Cold laminated film can increase the texture of the picture, and protect the picture, scratch and water resistant. However, the photo image can not be highly anti-corrosion and anti-ultraviolet erosion, ultraviolet light will penetrate the cold laminated film to fade the picture, and for a long time, the cold laminated film will also embrittlement. Can be widely used in wedding photos, oil painting production, calligraphy and painting, outdoor posters, advertising, all kinds of pictures, documents, materials... And so on. Used in large-scale advertising, architectural decoration renderings, background decoration, etc., the use of cold laminated film protection effect is better.

Model Selection

|

|

|

|

|

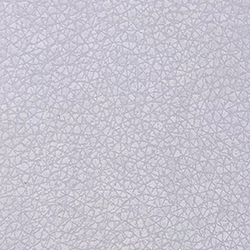

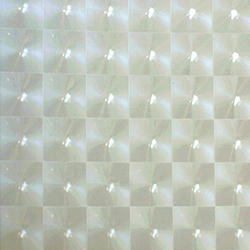

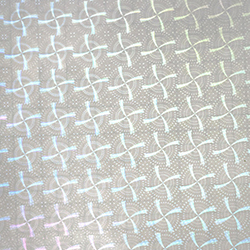

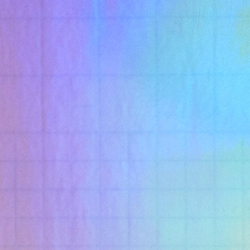

| Glossy Transparent Film | Matte Transparent Film | Frosted Film | Tinotron Film | Star Film |

|

|

|

|

|

| Cross Cloth Film | Skin Grain Film | Cat Eye Mask | Blower Film | Butterfly Film |

|

|

|

|

|

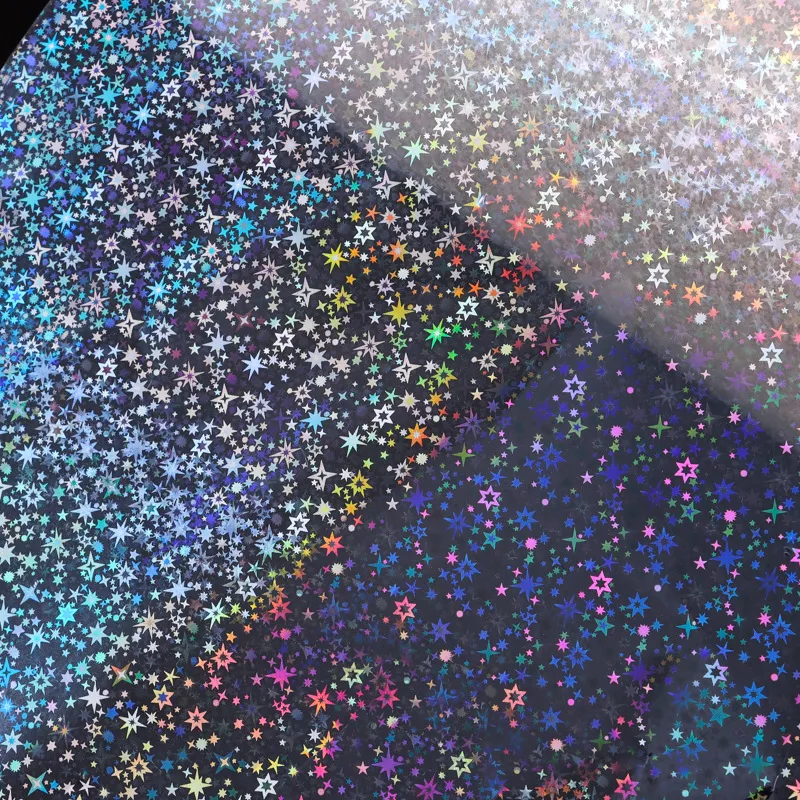

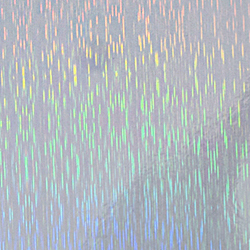

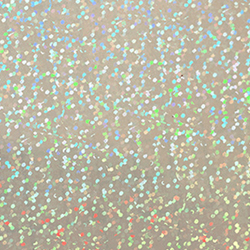

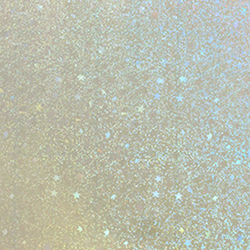

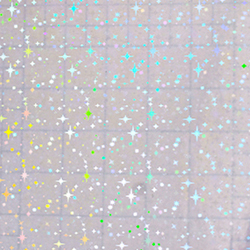

| Holography | Holographic Line | Holographic Dot | Holographic Meteor Film | Holographic Star Film |

|

|

|

|

|

| Holographic Circle Film | Shattered Glass Film | Holographic Snow Film | Holographic Fireworks Film | Holographic Love Film |

|

|

|

|

|

| Holographic Grid | Small Square Film | Holographic Flower | Holographic Pentagram | Christmas Ribbon |

|

|

Custom base pattern is available, Due to shooting lighting, effect map difference, please contact customer service real video/picture。 |

||

| Holographic Radius | Holographic Rice Pattern | |||

If Using:

1. Turn the pressure regulator handle on the box on both sides of the cold press machine, separate the upper and lower two axes, put the picture to be mounted and the cold press film into the two axes at the same time, turn the pressure regulator handle, so that the upper axis moves parallel down, when the pressure regulator handle feels suddenly relaxed, it means that the upper and lower two axes have been in contact, please do not continue to press down. Simply tighten the pressure regulator gently. If the pressure continues, the shaft will be deformed and the operation will fail

2. After the pressure is adjusted, the graph between the two axes and the cold-pressed film are withdrawn from between the two axes. Prepare to press the film.

Cold Laminated Film Common Question Treatment

Question 1. When a large area of the screen has the feeling of "fog"

1. Insufficient film pressure -- adjust the pressure of the cold mounting machine;

2. The two ends of the cold laminating machine are not smooth -- adjust the adjusting screws of the distance between the cold laminating machines to achieve equal distance;

3. Over-photo paper - the surface of the photo paper is uneven, generally about 25 degrees, placed 2-3 hours will automatically disappear, the higher the temperature will disappear faster;

4. Over PP glue --A. hand touch PP glue screen if there is no "rough" feeling, then according to the above method; B. There is a "rough" feeling that requires more PP backing glue;

5. Glue viscosity is not good at low temperature --A. Improve the use of ambient temperature. B. Replace the cold mounting film

Question 2. When there is a "white spot" behind the screen

1. The glue is not sticky enough --A. Increase the ambient temperature,B. Replace the cold mounting film;

2. Thin glue - the general distance is not long, the probability of greater before and after shutdown, generally pull off a few meters;

3.PP adhesive surface hand touch "rough" feeling --A. Replace PP adhesive,B. Or use studio film over the picture;

4. There is dust in the air --A. Purify the operating environment,B. Close the blower or air inlet source;

5. Water droplets (such as saliva) inadvertently splash on the surface of the spray painting --A. Pay attention when operating, especially when speaking, do not face the picture,B. Air temperature in dry environment, such as air conditioning, hot fan or ventilation.

Question 3. When there are "bubbles" immediately after painting

1. The glue does not "mature" -- change the cold mounting film

Question 4. It is fine after painting, but there are "bubbles" after leaving it for a while (or the next day).

1. The glue is not "matured" thoroughly -- open the cold mounting film

Pack and place in the air for 2-5 days to allow the glue to fully "mature" under natural conditions;

2. The picture is not sufficiently dry, especially in winter, because there are antifreeze components in the winter ink, which is not easy to volatilize completely.- Let the picture be fully dry, the general winter time is twice as long as summer and autumn above, and then over the painting (must pay attention to dust);

3. Large area single color such as: all black/all red, etc. --A. Light color,B. Replace ink,C. Fully dry the picture (completely dry),D. heat the picture,E. replace the more viscous cold mounting film, the thinner the better.

4. The ambient temperature is low, so that the cold laminating film surface is too hard -- improve the ambient temperature when using;

5. Cold mounting film is too thick -- replace it with a thin cold mounting film;

6. Roll up immediately after painting, the glue and the picture are not fully integrated - after painting, place it flat for more than 45 minutes and then roll it up.

7. Aging glue -- Replace the cold mounting film.

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(1)

Ownlikes Holographic Transparent Star Cold Laminated Film is very easy to work with and handles smoothly during application. It’s a reliable material that I keep coming back to.