Intelligent color changing temperature measuring sticker

Performance and Usage

The intelligent temperature measurement patch has unique color changing temperature display, digital display, reversible color change, and recording functions. It comes with adhesive and is used on the indoor busbar contacts, isolation switch contacts, and the casings of transformers, motors, capacitors, and other equipment in substations. Used to monitor the temperature of busbar connections and electrical equipment enclosures

The three colors of the intelligent temperature measurement patch represent three different temperature conditions, with a large contrast in color changes, which is very clear and concise

① White indicates that the location has never reached the rated temperature

② Red indicates that it is currently in an over temperature state

③ Black indicates that it has reached the rated temperature before and has now fallen below the rated temperature

Features

It has reversible and recording functions, and can still be used after color change. It is exclusively produced in China and has color display and digital display functions. White, red, and black colors represent different temperature conditions, with large color contrast. It is equipped with a protective film and has good waterproof, dustproof, anti fouling, and oil proof properties

Irreversible special flashback sticker for car lights

The flashback sticker of the car lamp undergoes a color change due to electron transfer at a specific temperature, causing the molecular structure of the organic compound to change. When the temperature reaches the set temperature, it changes from colorless and transparent to the preset color, and it is irreversible

Temperature: 60 ℃ -100 ℃ C

Color rendering series (temperature 60 ℃): colorless red/colorless green/colorless blue

Conventional size: automotive parts universal spot stock 60 ℃/65 ℃/70 ℃/75 ℃/80 ℃/90 ℃/100 ℃ irreversible special car light tempering sticker

Low temperature color changing sticker

Low temperature color changing sticker, a temperature controlled color changing material that integrates advanced technology, can trigger magical color changes within a specific temperature range. The principle is that when the ambient temperature reaches 7-13 ℃, the clever transfer of electrons will guide the molecular structure of organic matter to rearrange, thereby triggering a change in color state.

The color expression of this color changing substance is amazing, not only with bright colors, but also with the ability to achieve flexible transitions from colored to colorless, or from colorless to colored, like a visual magic show. Imagine a sticker displaying different colors in front of your eyes as the temperature changes. This wonderful experience will undoubtedly add a sense of mystery and fun to your product.

Whether on the body of chilled beer bottles or on the packaging of cold drinks and red wine, low-temperature color changing stickers can become a beautiful scenery. When the ambient temperature drops to a specified range, stickers will be like a paintbrush in the artist's hand, depicting a brand new world of colors, attracting consumers' attention, and enhancing the attractiveness of the product.

The low-temperature color changing stickers we provide feature a colorless to red transformation, which is a striking color change that can be the focus of attention whether in refrigerated display cabinets or outdoor gatherings in summer. Let low-temperature color changing stickers bring the perfect combination of technology and art to your products, leading the trend and creating infinite possibilities.

Wrinkles and skewness issues in PE label labeling

Once, a labeling company reported to us that their daily chemical labels had serious wrinkles and skewness during the automatic labeling process. They hoped that the author could help analyze the reasons. So our colleagues conducted an on-site investigation at the customer's factory. In the investigation, it was found that the labeling production line speed of the daily chemical enterprise is quite fast, reaching 300 bottles/minute. The problematic labels in this batch are made of PE material, which is relatively soft. Under normal circumstances, even if the bottle body is compressed after labeling, the labels will not wrinkle. It is precisely for this reason that the label company chose PE material to process the labels.

But it is precisely because the material is too soft that the stiffness is not enough when labeling at high speed, resulting in wrinkles and skewness of the label. For customers who encounter high-speed labeling and have certain requirements for the stiffness and softness of the label material, it is recommended to choose PE/PP co extrusion material. This material has unidirectional stretchability, that is, one side is very soft while the other side is very strong. Eli Lilly's Fasen Clear and Plaimans materials are representatives of this material.

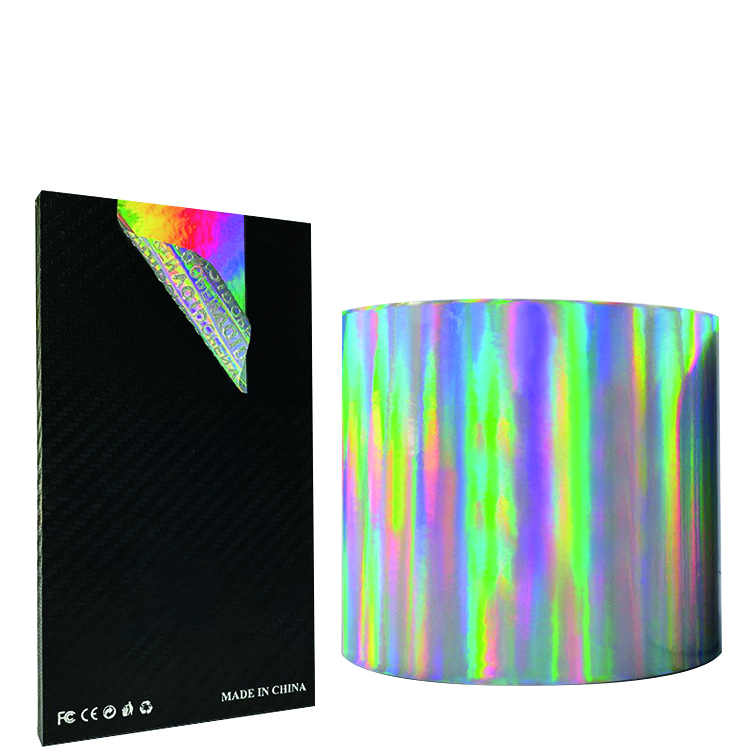

Hot stamping film

Hot stamping film, also known as aluminum foil (the term aluminum foil is more commonly used in the printing industry), is a hot stamping material made by coating and vacuum evaporating a thin film substrate with a layer of metal foil. The thickness of aluminum foil is generally (12, 16, 18, 20)μ m. 500-1500mm wide. Electrochemical aluminum foil is made by coating a release layer, a color layer, vacuum aluminum plating, and then coating a glue layer on a thin film, and finally rewinding the finished product

1. Specifications:

Thickness: 0.012mm Width: 0.64m, 1.28m

Length: 120m, 180m, 240m, 300m, 360m, 1000m, 3000m

Standard specification: 0.012mm * 0.64m * 120m

2. Colors: Gold, Silver, Red, Green, Blue, Black, Bronze, Coffee, Matte Gold, Matte Silver, Pearl, Laser, Pigment Foil, etc

3. Type: 1. Sheet 2. Over plastic type 3. Non adhesive type 4. Spray 5. Water pine paper 6. Pigment type 7. Pearl type 8. Hot cloth type

4. Application scope: Suitable for hot stamping various gift packaging boxes, food packaging boxes, tobacco and alcohol packaging boxes, labels, red envelopes, couplets, spring couplets, red envelopes, holiday greeting cards, invitation cards, festive supplies, calendars, written binding tags, trademarks, cosmetics lids, cosmetics hoses, handbags and other paper boxes as well as stationery

5. Hot stamping on various types of paper or cardboard, laminated paper, and plastics such as PC, PS,PP,PET,PVC,OPP,ABS, Imitation leather, etc

6. Product features: clear and beautiful patterns, bright colors, dazzling, wear-resistant, weather resistant, clear contours, suitable for fine patterns, large, medium and small area hot stamping, flat hot stamping and rolling hot stamping, as well as manual, semi-automatic, fully automatic and other hot stamping machines

7. Weight: Gross weight: 1.7KG/roll Net weight: 1.5KG/roll

8. Outer box size: according to customer requirements

9. Packing list: Inner packaging: PET packaging film Outer packaging: 15 standard rolls per box in cardboard boxes

10. Reference hot stamping temperature: Paper type/Over molded type/Spray type/Non adhesive type/Water pine paper type/Pigment type/Pearl type: 100 ℃ -130 ℃, Hot cloth type: 80 ℃ -145 ℃

11. Reference hot stamping time: 0.3S-0.8S

12. Storage conditions: anti pressure, moisture-proof, heat-resistant, sun proof, stored in a cool and ventilated place, with a shelf life of two years

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.