Hot stamping film, also known as electrolytic aluminum (the name of electrolytic aluminum is used more in the printing industry), is a hot stamping material made of a layer of metal foil on the film substrate by coating and vacuum evaporation. The thickness of electrochemical aluminum is generally (12, 16, 18, 20) μm, 500 ~ 1500mm wide. Electrochemical aluminum foil is coated on the film sheet with a separation layer, a color layer, vacuum aluminum plating and then coated with adhesive layer, and finally made by the finished product rewinding,OwnLikes electrochemical aluminum foil is generally 4~5 layers.

Product Review:Hot stamping film, also known as electrolytic aluminum (the name of electrolytic aluminum is used more in the printing industry), is a hot stamping material made of a layer of metal foil on the film substrate by coating and vacuum evaporation. The thickness of electrochemical aluminum is generally (12, 16, 18, 20) μm, 500 ~ 1500mm wide. Electrochemical aluminum foil is coated on the film sheet with a separation layer, a color layer, vacuum aluminum plating and then coated with adhesive layer, and finally made by the finished product rewinding,OwnLikes electrochemical aluminum foil is generally 4~5 layers.

Basal film layer

The domestic general use of 16μm thick bidirectional tensile polyester film; The main function is to support the continuous action attached to the above coating and facilitate the pressing working time. In this way, it is clear that the base film can not be deformed due to temperature rise during the hot stamping process, and should have high strength, tensile strength, high temperature resistance and other properties.

Abscission layer

Generally, it is mainly coated with organic silicone resin. The main component of the second layer of separation layer in electrochemical aluminum foil is silicone resin, its main role is after hot stamping, whether it is before heating or pressurizing, it will make the color, aluminum, adhesive layer, can quickly be removed from the film and transferred to bond on the surface of the hot stamping object, so that there is a process in the electrochemical aluminum and composition is the separation layer, And in the detached layer there is a chemical (silicone resin). It is mainly to help the material transfer well, and the main role of the finished bronzing materials we do is to put a variety of bronzing materials should be or is printed on a variety of items, but also to achieve the effect of printing on it. The main component in the base film layer is (polyester film). It is mainly to prevent the stretching and change of hot stamping in the process of hot stamping, so that the process of hot stamping is intact. It doesn't change at all because of the high temperature. And high strength, high temperature resistance, tensile properties. The separation layer should have better separation performance, otherwise it will make the pictures and images after hot printing blurred, exposing the bottom hair, affecting the product quality of hot printing.

Chromatophore

The main component of the color layer

Synthetic resins and dyes suitable for film forming, heat resistance and transparency.

The color layer has two main functions

1. Display color.

2. Protect the aluminized layer of images printed on the surface of articles from oxidation.

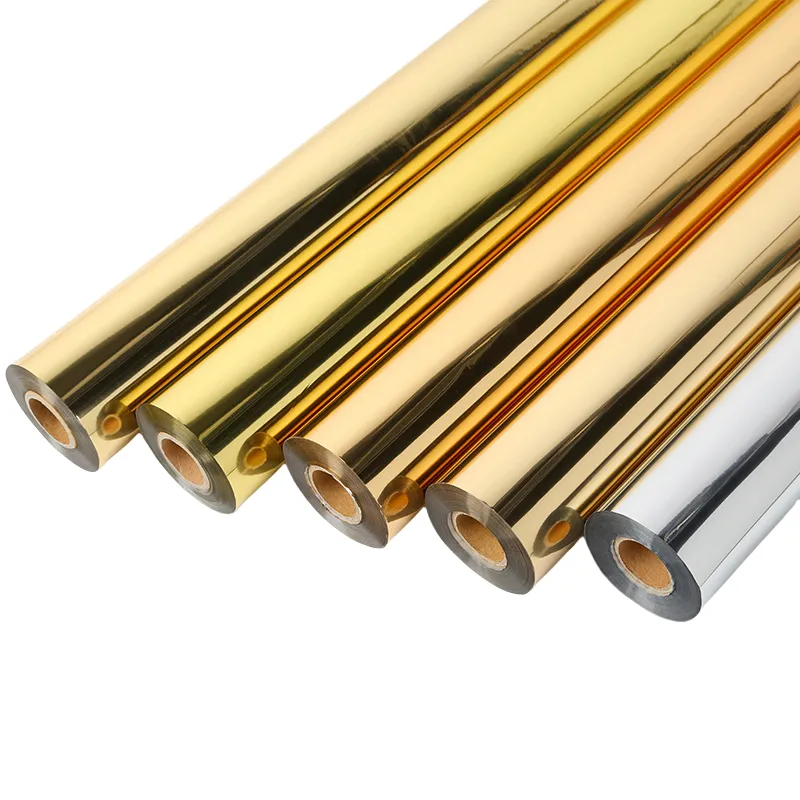

The color of the electrochemical aluminum foil is orange, yellow, gray, red, green and so on. The color of the color layer is endowed with luster after the aluminum plating layer, and the color has a certain change, such as yellow after aluminum plating for gold, colorless after aluminum plating for silver and so on. The requirements for the color coating are fine without any small particles, so as to avoid the appearance of sand holes and damage the uniformity of the coating.

3.Color classification

Aluminized coating

Aluminum plating layer is the colored layer of film, placed in the vacuum chamber of continuous aluminum plating machine, under a certain vacuum degree, through resistance heating, the aluminum wire melting and continuous evaporation to the color of the film, the formation of aluminum plating layer, the main role is to reflect the light, change the color of the color of the layer, and make it shine.

Adhesive layer

The adhesive layer is generally fusible thermoplastic resin (there are many kinds of it) through the coating machine on the aluminum layer, which is dried into the adhesive layer. The main function of the adhesive layer is to bond the hot printing material to the hot object.

Product Category:

Cold Pressing Series:

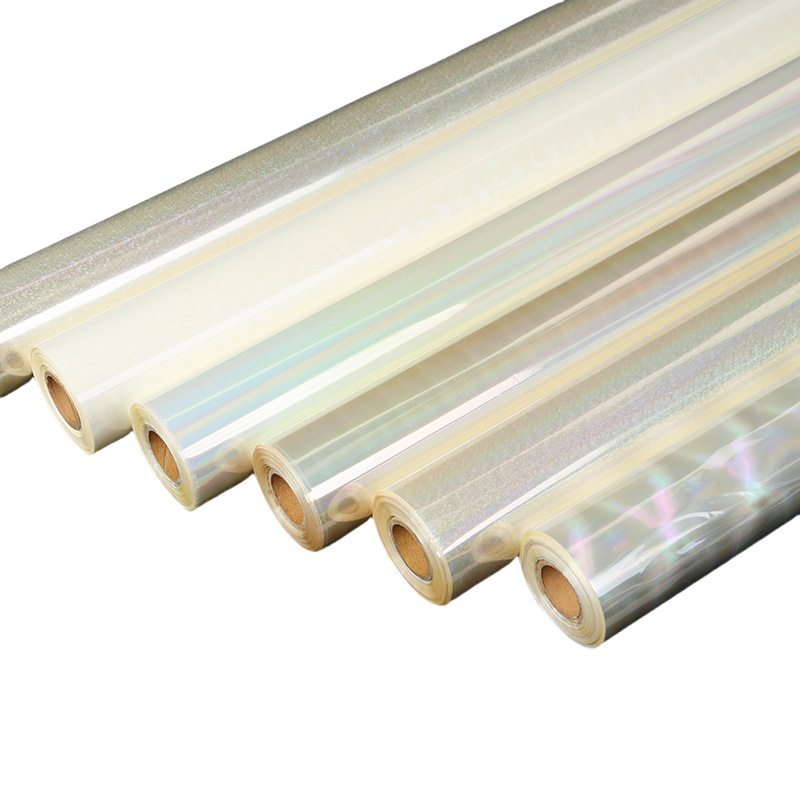

1. Flexographic cold ironing film (uv light solid) is suitable for quick ironing of letterpress drum, diffused film, ordinary film, color release.

2. Offset printing cold stamping film: suitable for offset printing cold stamping, fast speed, clear dot, laser film and ordinary film, color variety.

Hot Stamping Series: Hot stamping covers paper, fabric (high temperature and washable)PE,PPPVC ABS and other substrates

Transfer Film Series: Transfer including paper, fabric leather and other substrates.

Gold film Series: including manual stripping and machine stripping of gold foil. Suitable for manual pasting process. Such as: Buddha, plaque gold technology

Electrolytic Aluminum Foil Paper Film Product

Frequently Asked Questions

Question 1: What do you have in stock?

A: There are generally common colors. About the purchase of stock need to consult customer service in advance, do not rule out some color models just out of stock.

Question 2: What is the MOQ if I want to make it to order?

A: The minimum order quantity is generally about 10000M, less than 10,000 meters depending on the situation to order, the delivery time is generally about 10 days, urgent orders need to be explained in advance.

Question 3: There are several prices of your gold stamping paper, what is the difference in quality?

A: The price of different colors is not the same, the normal gold stamping effect will be more beautiful, you can according to the use of their own products, subscribe for your products.

Question 4: Can you provide samples if we need them?

A: Small roll sample and sample book can be provided free of charge, UPS/ federal /DHL express delivery.

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(2)

I tried the Gold Silver Hot Stamping Film, and it came out looking really clean. The shine is just right—not too flashy but still eye-catching. It sticks well and adds a premium touch to labels or packaging.

Used the Gold Silver Hot Stamping Film—adds a nice metallic shine without being over-the-top. Pressed clean and stuck well. Great for labels or gift packaging when you want that extra pop.